SS Pipe Fittings, SS Flange, Stainless steel Socket weld, Threaded Pipe Fittings

A403 Stainless Steel Pipe Fittings are versatile components designed to ensure seamless flow and connection in piping systems across various industries. Known for their exceptional resistance to corrosion, heat, and chemical exposure. Available in a wide array of designs like elbows, tees, reducers, and caps, they accommodate complex piping layouts with ease. Crafted from premium stainless steel grades such as 304, 316, and duplex variants, these fittings combine durability with precision engineering. Whether for high-pressure systems or environments requiring strict hygiene standards, SS Pipe Fittings deliver unmatched performance, reliability, and longevity.

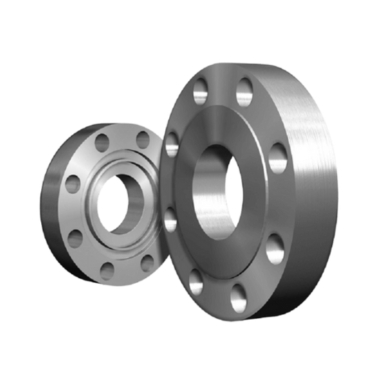

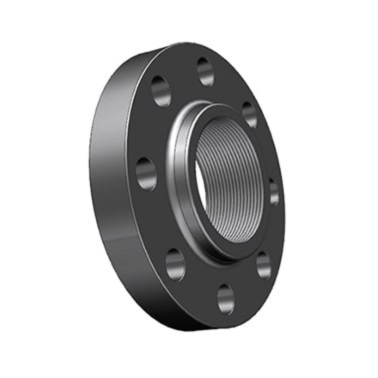

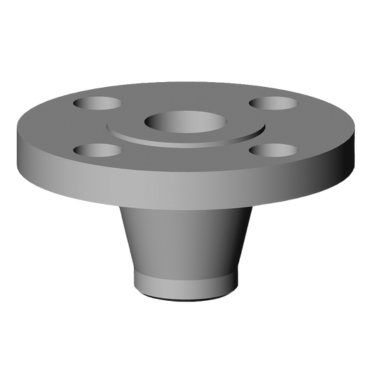

A182 Stainless Steel Flanges are critical components used to connect pipes, valves, pumps, and other equipment in a piping system, ensuring secure and leak-proof joints. Renowned for their excellent resistance to corrosion, high temperatures, and mechanical stress. They come in various types, including slip-on, weld neck, blind, socket weld, threaded, and lap joint flanges, catering to diverse application needs. Manufactured from high-grade stainless steel such as 304/304L, 316L, 321/321h, 310/310S these flanges meet rigorous standards like ASME, ANSI, DIN, and EN. Their robust design and precision engineering enable them to withstand challenging environments, delivering reliable performance in both standard and custom configurations.

Ample Alloys is a trusted manufacturer and supplier of premium-quality stainless steel products. We specialize in pipe fittings, flanges, and other industrial components tailored to diverse applications.

ASTM A403 pipe fittings, ASTM A182 Flange, A182 Forged Fittings, SS 304/304L pipe fittings & flange, SS 316/316L pipe fittings & flange, SS 321/321h pipe fittings & flange, SS 310/310S pipe fittings & flange

A403 SS Pipe Fittings Specifications

Size Range

Seamless Fittings: 1/2" - 24"

Welded Fittings: 4" - 72"

Standards / Dimension

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10, ASTM A403, ASME SA403

Schedule

Schedule 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS

A182 SS Pipe Flange Specifications

Size Range

1/2″ (15 NB) to 48″ (1200NB)

Standards / Dimension

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API-605, ASA, AWWA, Custom Drawings

Pressure Rating

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

| Standard | Grade | UNS | EN | DIN | JIS | GOST | BS | AFNOR |

|---|---|---|---|---|---|---|---|---|

| ASTM A182 / A403 | 304 | S30400 | 1.4301 (X5CrNi18-10) | 1.4301 | SUS304 | 08Х18Н10 | 304S15 | Z6CN18-09 |

| ASTM A182 / A403 | 304L | S30403 | 1.4307 (X2CrNi18-9) | 1.4307 | SUS304L | 03Х18Н11 | 304S11 | Z3CN18-09 |

| ASTM A182 / A403 | 304H | S30409 | 1.4948 | 1.4948 | SUS304H | 08Х18Н10Т | 304S51 | Z6CN18-10 |

| ASTM A182 / A403 | 316 | S31600 | 1.4401 (X5CrNiMo17-12-2) | 1.4401 | SUS316 | 08Х17Н13М2 | 316S31 | Z6CND17-11 |

| ASTM A182 / A403 | 316L | S31603 | 1.4404 (X2CrNiMo17-12-2) | 1.4404 | SUS316L | 03Х17Н14М3 | 316S11 | Z2CND17-12 |

| ASTM A182 / A403 | 316H | S31609 | 1.4919 | 1.4919 | SUS316H | 08Х17Н13М2Т | 316S51 | Z6CND17-12T |

| ASTM A182 / A403 | 316Ti | S31635 | 1.4571 (X6CrNiMoTi17-12-2) | 1.4571 | SUS316Ti | 10Х17Н13М2Т | 320S31 | Z6CNDT17-12 |

| ASTM A182 / A403 | 317 | S31700 | 1.4449 (X6CrNiMo18-12-3) | 1.4449 | SUS317 | 08Х18Н12М3 | 317S16 | Z3CND18-13-04 |

| ASTM A182 / A403 | 317L | S31703 | 1.4438 (X2CrNiMo18-15-3) | 1.4438 | SUS317L | 03Х18Н12М3 | 317S12 | Z2CND18-14-03 |

| ASTM A182 / A403 | 321 | S32100 | 1.4541 (X6CrNiTi18-10) | 1.4541 | SUS321 | 08Х18Н10Т | 321S12 | Z6CNT18-10 |

| ASTM A182 / A403 | 321H | S32109 | 1.4878 | 1.4878 | SUS321H | 08Х18Н10Т | 321S51 | Z6CNT18-10T |

| ASTM A182 / A403 | 347 | S34700 | 1.4550 (X6CrNiNb18-10) | 1.4550 | SUS347 | 08Х18Н12Б | 347S17 | Z6CNNb18-10 |

| ASTM A182 / A403 | 347H | S34709 | 1.4961 | 1.4961 | SUS347H | 08Х18Н12БТ | 347S51 | Z6CNNb18-12T |

| ASTM A182 / A403 | 310 | S31000 | 1.4840 (X15CrNi25-20) | 1.4840 | SUS310 | 20Х25Н20С2 | 310S24 | Z20CN25-20 |

| ASTM A182 / A403 | 310S | S31008 | 1.4845 (X8CrNi25-21) | 1.4845 | SUS310S | 20Х23Н18 | 310S16 | Z8CN25-21 |

| ASTM A182 / A403 | 904L | N08904 | 1.4539 (X1NiCrMoCu25-20-5) | 1.4539 | SUS890L | ХН35МДТ | 904S13 | Z2CNDU25-20-05 |

| Grade | C (max) | Mn (max) | Si (max) | P (max) | S (max) | Cr | Ni | Mo | N (max) | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 0.75 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 | - | - | - |

| 304L | 0.03 | 2.00 | 0.75 | 0.045 | 0.03 | 18.0-20.0 | 8.0-12.0 | - | - | - |

| 304H | 0.04-0.10 | 2.00 | 0.75 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 | - | - | - |

| 316 | 0.08 | 2.00 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - | - |

| 316L | 0.03 | 2.00 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - | - |

| 316H | 0.04-0.10 | 2.00 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - | - |

| 316Ti | 0.08 | 2.00 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.5-14.0 | 2.0-3.0 | - | Ti: ≥5xC |

| 317 | 0.08 | 2.00 | 0.75 | 0.045 | 0.03 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | - | - |

| 317L | 0.03 | 2.00 | 0.75 | 0.045 | 0.03 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | - | - |

| 321 | 0.08 | 2.00 | 0.75 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 | - | - | Ti: ≥5xC |

| 321H | 0.04-0.10 | 2.00 | 0.75 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 | - | - | Ti: ≥4xC |

| 347 | 0.08 | 2.00 | 0.75 | 0.045 | 0.03 | 17.0-19.0 | 9.0-13.0 | - | - | Nb: ≥10xC |

| 347H | 0.04-0.10 | 2.00 | 0.75 | 0.045 | 0.03 | 17.0-19.0 | 9.0-13.0 | - | - | Nb: ≥10xC |

| 310 | 0.25 | 2.00 | 1.50 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | - | - | - |

| 310S | 0.08 | 2.00 | 1.50 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | - | - | - |

| 904L | 0.02 | 2.00 | 1.00 | 0.045 | 0.035 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | - | Cu: 1.0-2.0 |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (% min) | Hardness (HB max) | Impact Toughness (J) |

|---|---|---|---|---|---|

| 304 | 515 min | 205 min | 40 | 201 | High |

| 304L | 485 min | 170 min | 40 | 201 | High |

| 304H | 515 min | 205 min | 40 | 201 | High |

| 316 | 515 min | 205 min | 40 | 217 | High |

| 316L | 485 min | 170 min | 40 | 217 | High |

| 316H | 515 min | 205 min | 40 | 217 | High |

| 316Ti | 515 min | 205 min | 40 | 217 | High |

| 317 | 515 min | 205 min | 40 | 217 | High |

| 317L | 485 min | 170 min | 40 | 217 | High |

| 321 | 515 min | 205 min | 40 | 217 | High |

| 321H | 515 min | 205 min | 40 | 217 | High |

| 347 | 515 min | 205 min | 40 | 217 | High |

| 347H | 515 min | 205 min | 40 | 217 | High |

| 310 | 520 min | 205 min | 40 | 217 | High |

| 310S | 520 min | 205 min | 40 | 217 | High |

| 904L | 490 min | 220 min | 35 | 192 | High |

Available Products of Stainless Steel Buttweld Fittings

Stainless Steel Tee

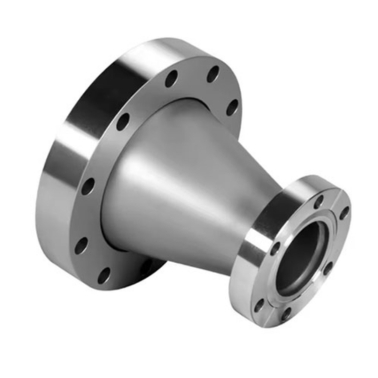

A182 SS Reducer

Stainless Steel Cross

Stainless Steel Stub End

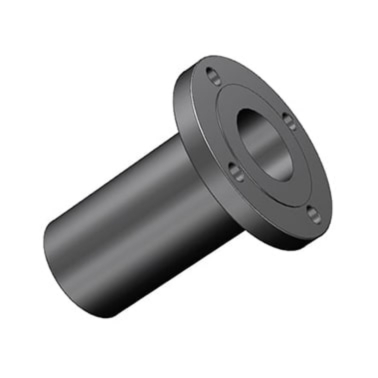

Available Products of Stainless Steel Forged Fittinhgs

SS Socket Weld & Thredaed Tee

SS Socket Weld & Thredaed Coupling

SS Socket Weld & Thredaed Cap

SS Socket Weld & Thredaed Boss

SS Socket Weld & Thredaed Pipe Nipple

SS Socket Weld & Thredaed Plug

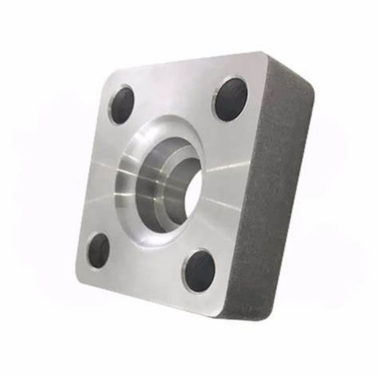

Available Products of Stainless Steel Flange

Why Ample Alloys Stainless Steel Fittings!

Choose Ample Alloys for SS Fittings and Flanges to experience exceptional quality, precision engineering, and reliable performance. We deliver tailored solutions, meeting international standards, for diverse industrial applications.

Superior Quality

Products crafted from premium-grade stainless steel ensuring excellent durability and corrosion resistance.

Wide Range of Offerings

Comprehensive selection of fittings, including buttweld, socket weld, threaded fittings, slip-on, weld neck, blind flanges.

Industry Standards Compliance

Adherence to international standards such as ASTM, ASME, DIN, and EN for assured reliability.

Trusted Expertise

A proven track record of excellence and reliability in manufacturing stainless steel products.

Stainless steel fittings and flanges are used to connect, redirect, and seal piping systems in industries like oil and gas, petrochemicals, water treatment, and food processing.

They are widely used in industries like oil and gas, petrochemicals, power plants, water treatment, food and beverage, and pharmaceuticals.

They typically meet standards such as ASTM, ASME, ANSI, DIN, and EN for quality and performance.