ASME/ANSI B16.48 Spectacle Blind Flange Supplier

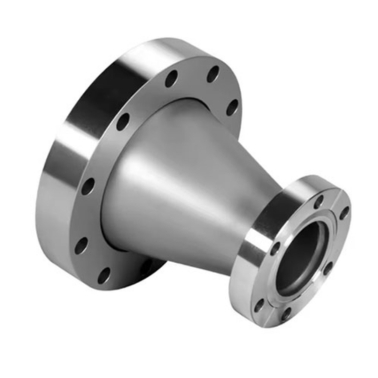

A spectacle blind flange, often referred to simply as a "spectacle blind," is a specialized piping component used to seal off a pipeline for maintenance or system isolation. It consists of two metal discs: one solid and one with a hole. The solid disc is used to block the flow of fluid, while the perforated disc can be used when flow is required. The name "spectacle" comes from the shape of the two discs, resembling a pair of spectacles or glasses when viewed from the side. Typically made from materials like carbon steel, stainless steel, or alloy steels, spectacle blind flanges are used in industries such as oil and gas, chemical processing, and water treatment, providing a reliable method of controlling flow and ensuring safety during system shutdowns or maintenance. They are designed to be bolted between two flanges and are available in various pressure ratings and sizes to suit different operational requirements.

Ample Alloys is a trusted supplier known for its commitment to quality, reliability, and exceptional customer service. With a focus on meeting industry standards, We ensures timely deliveries and precise solutions tailored to customer needs. Our attention to detail and technical expertise have earned them a strong reputation as a dependable partner in the metal industry.

High-Pressure Spectacle Blind Flange, ANSI Spectacle Blind Flange, Forged Spectacle Blind Flange, Piping Isolation Flange, Blind Flange with Hole, Carbon Steel, Stainless Steel Spectacle Blind Flange, Perforated Spectacle Blind Flange

Spectacle Blind Flange

Size Range

15mm ( 1/2" NPS ) up to 600mm ( 24" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

Flange Face Type

FF—Flat Face, RF—Raised Face, FM—Female Face, M—Male Face, T—Tongue Face, G—Groove Face, RJ—Ring Joint.

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ANSI/ASME B16.48, BS4504, BS 10, EN-1092, DIN

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64.

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

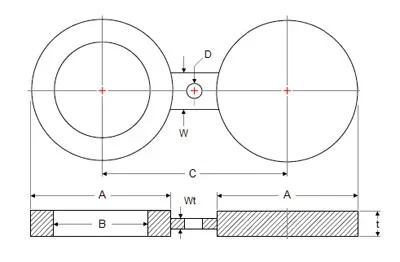

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 45 | 16 | 60 | 3 | 38 |

| 3/4 | 54 | 21 | 70 | 3 | 38 |

| 1 | 64 | 27 | 80 | 3 | 38 |

| 1.1/4 | 73 | 42 | 90 | 6.4 | 38 |

| 1.1/2 | 83 | 48 | 100 | 6.4 | 38 |

| 2 | 102 | 61 | 120 | 6.4 | 51 |

| 2.1/2 | 107 | 73 | 140 | 6.4 | 51 |

| 3 | 133 | 89 | 150 | 6.4 | 64 |

| 3.1/2 | 159 | 102 | 175 | 9.7 | 64 |

| 4 | 172 | 114 | 190 | 9.7 | 64 |

| 5 | 194 | 141 | 215 | 9.7 | 76 |

| 6 | 219 | 168 | 240 | 12.7 | 76 |

| 8 | 276 | 219 | 300 | 12.7 | 76 |

| 10 | 337 | 273 | 360 | 15.7 | 102 |

| 12 | 406 | 324 | 430 | 19.1 | 102 |

| 14 | 448 | 356 | 475 | 19.1 | 108 |

| 16 | 511 | 406 | 460 | 22.4 | 108 |

| 18 | 546 | 457 | 580 | 25.4 | 114 |

| 20 | 603 | 508 | 635 | 28.4 | 121 |

| 24 | 714 | 610 | 750 | 31.8 | 140 |

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 38 |

| 1.1/4 | 79 | 42 | 100 | 6.4 | 38 |

| 1.1/2 | 92 | 48 | 115 | 6.4 | 38 |

| 2 | 108 | 61 | 125 | 9.7 | 51 |

| 2.1/2 | 127 | 73 | 150 | 9.7 | 51 |

| 3 | 146 | 89 | 170 | 9.7 | 64 |

| 3.1/2 | 162 | 102 | 185 | 12.7 | 64 |

| 4 | 178 | 114 | 200 | 12.7 | 64 |

| 5 | 213 | 141 | 235 | 15.7 | 76 |

| 6 | 248 | 168 | 270 | 15.7 | 76 |

| 8 | 305 | 219 | 330 | 22.4 | 76 |

| 10 | 359 | 273 | 385 | 25.4 | 102 |

| 12 | 419 | 324 | 450 | 28.4 | 102 |

| 14 | 483 | 356 | 515 | 31.8 | 108 |

| 16 | 536 | 406 | 570 | 38.1 | 108 |

| 18 | 594 | 457 | 630 | 41.1 | 114 |

| 20 | 651 | 508 | 685 | 44.5 | 121 |

| 24 | 772 | 610 | 810 | 50.8 | 140 |

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 57 |

| 1.1/4 | 79 | 37 | 100 | 9.7 | 57 |

| 1.1/2 | 92 | 43 | 115 | 9.7 | 67 |

| 2 | 108 | 55 | 125 | 9.7 | 57 |

| 2.1/2 | 127 | 67 | 150 | 12.7 | 67 |

| 3 | 146 | 83 | 170 | 12.7 | 67 |

| 3.1/2 | 159 | 96 | 185 | 15.7 | 76 |

| 4 | 191 | 108 | 215 | 15.7 | 76 |

| 5 | 238 | 135 | 265 | 19.1 | 86 |

| 6 | 264 | 162 | 290 | 22.4 | 86 |

| 8 | 318 | 212 | 350 | 28.4 | 95 |

| 10 | 397 | 265 | 430 | 35.1 | 105 |

| 12 | 454 | 315 | 490 | 41.1 | 105 |

| 14 | 489 | 346 | 525 | 44.5 | 114 |

| 16 | 562 | 397 | 605 | 50.8 | 124 |

| 18 | 610 | 448 | 655 | 53.8 | 133 |

| 20 | 679 | 497 | 725 | 63.5 | 133 |

| 24 | 787 | 597 | 840 | 73.2 | 152 |

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 60 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 6.4 | 41 |

| 1 | 76 | 27 | 100 | 6.4 | 57 |

| 1.1/4 | 86 | 37 | 110 | 9.7 | 57 |

| 1.1/2 | 95 | 43 | 125 | 9.7 | 67 |

| 2 | 140 | 55 | 165 | 12.7 | 57 |

| 2.1/2 | 162 | 67 | 190 | 12.7 | 67 |

| 3 | 165 | 83 | 190 | 15.7 | 67 |

| 4 | 203 | 108 | 235 | 19.1 | 76 |

| 5 | 244 | 135 | 280 | 22.4 | 86 |

| 6 | 286 | 162 | 320 | 25.4 | 86 |

| 8 | 356 | 212 | 395 | 35.1 | 95 |

| 10 | 432 | 265 | 470 | 41.1 | 105 |

| 12 | 495 | 315 | 535 | 47.8 | 105 |

| 14 | 518 | 346 | 560 | 53.8 | 114 |

| 16 | 572 | 397 | 615 | 60.5 | 124 |

| 18 | 635 | 448 | 685 | 66.5 | 133 |

| 20 | 696 | 497 | 750 | 73.2 | 133 |

| 24 | 835 | 597 | 900 | 88.9 | 152 |

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 61 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 9.7 | 41 |

| 1 | 76 | 27 | 100 | 9.7 | 64 |

| 1.1/4 | 86 | 35 | 110 | 9.7 | 64 |

| 1.1/2 | 95 | 41 | 125 | 12.7 | 70 |

| 2 | 140 | 53 | 165 | 12.7 | 70 |

| 2.1/2 | 162 | 63 | 190 | 15.7 | 76 |

| 3 | 172 | 78 | 205 | 19.1 | 76 |

| 4 | 206 | 102 | 240 | 22.4 | 89 |

| 5 | 251 | 128 | 290 | 28.4 | 89 |

| 6 | 279 | 154 | 320 | 35.1 | 89 |

| 8 | 349 | 203 | 395 | 41.1 | 102 |

| 10 | 432 | 255 | 480 | 50.8 | 114 |

| 12 | 518 | 303 | 570 | 60.5 | 114 |

| 14 | 575 | 333 | 635 | 66.5 | 127 |

| 16 | 638 | 381 | 705 | 76.2 | 133 |

| 18 | 702 | 429 | 775 | 85.9 | 146 |

| 20 | 752 | 478 | 830 | 95.3 | 152 |

| 24 | 899 | 575 | 990 | 111.3 | 178 |

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 67 | 16 | 90 | 9.7 | 38 |

| 3/4 | 73 | 21 | 95 | 9.7 | 41 |

| 1 | 83 | 27 | 110 | 9.7 | 64 |

| 1.1/4 | 102 | 35 | 130 | 12.7 | 64 |

| 1.1/2 | 114 | 41 | 145 | 15.7 | 70 |

| 2 | 143 | 53 | 170 | 15.7 | 70 |

| 2.1/2 | 165 | 63 | 195 | 19.1 | 76 |

| 3 | 194 | 78 | 230 | 22.4 | 76 |

| 4 | 232 | 102 | 275 | 28.4 | 89 |

| 5 | 276 | 128 | 325 | 35.1 | 89 |

| 6 | 314 | 154 | 370 | 41.1 | 89 |

| 8 | 384 | 198 | 440 | 53.8 | 102 |

| 10 | 473 | 248 | 540 | 66.5 | 114 |

| 12 | 546 | 289 | 620 | 79.2 | 114 |

Blind Spectacle Flange Standards

The standards for blind spectacle flanges ensure that these components meet the necessary requirements for performance, safety, and compatibility in piping systems. Some key standards for blind spectacle flanges include:

- ASME/ANSI Standards (American):

- ASME B16.5 – Pipe Flanges and Flanged Fittings (NPS 1/2" to 24").

- ASME B16.47 – Large Diameter Steel Flanges (Series A & B, NPS 26" to 60").

- ASME B16.36 – Orifice Flanges.

- ASME B16.48 – Line Blanks (Spectacle, Spade, and Spacer Flanges).

- ANSI B16.1 – Cast Iron Flanges and Flanged Fittings.

- ANSI B16.42 – Ductile Iron Pipe Flanges and Flanged Fittings.

- ISO Standards (International)

- ISO 7005-1 – Steel Flanges for General Applications.

- ISO 7005-2 – Cast Iron Flanges.

- ISO 7005-3 – Copper Alloy Flanges.

- EN Standards (European)

- EN 1092-1 – Steel Flanges.

- EN 1092-2 – Cast Iron Flanges.

- EN 1092-3 – Copper Alloy Flanges.

- EN 1092-4 – Aluminium Alloy Flanges.

- DIN Standards (German)

- DIN 2527 – Blind Flanges.

- DIN 2576 – Slip-On Flanges (PN 10).

- DIN 2633 – Weld Neck Flanges (PN 16).

- DIN 2634 – Weld Neck Flanges (PN 25).

- DIN 2635 – Weld Neck Flanges (PN 40).

- JIS Standards (Japanese)

- JIS B2220 – Steel Pipe Flanges.

- GOST Standards (Russian)

- GOST 12820 – Flat Flanges for Steel Pipe Joints.

- GOST 12821 – Steel Welded Flanges for High-Pressure Applications.

- GOST 33259 – Flange Connections for Industrial Equipment and Pipelines.

- BS Standards (British)

- BS 4504 – Circular Flanges for Pipes, Valves, and Fittings.

- BS 10 – Specification for Flanges and Bolting.

- API Standards (Oil & Gas)

- API 6A – Wellhead and Christmas Tree Equipment Flanges.

- API 605 – Large-Diameter Carbon Steel Flanges (merged into ASME B16.47 Series B).

- AWWA Standards (Waterworks)

- AWWA C207 – Steel Ring Flanges for Waterworks Service.

- MSS Standards (Manufacturer's Standardization Society)

- MSS SP-44 – Steel Pipe Flanges (merged into ASME B16.47 Series A).

- MSS SP-51 – Flanges for Glass-Lined Equipment.

- Material-Specific Standards (ASTM)

- ASTM A105 – Carbon Steel Forged Flanges.

- ASTM A182 – Alloy and Stainless Steel Forged Flanges.

- ASTM A350 – Carbon and Low-Alloy Steel Flanges for Low-Temperature Service.

- ASTM A694 – High-Strength Carbon and Alloy Steel Flanges for High-Pressure Applications.

- Other Regional and Specialized Standards

- KS B1511 – Korean Standard Flanges.

- NF E29-206 – French Standard Flanges.

- SANS 1123 – South African Standard for Steel Flanges.

Why Ample Alloys For Spectacle Blind Flange!

Ample Alloys provides competitive pricing, on-time delivery, and exceptional after-sales support, making it the preferred choice for high-quality Spectacle Blind Flanges worldwide.

High-Quality Products

Ensures durable and precisely engineered spectacle blind flanges.

Industry Standards Compliance

Meets the highest standards for performance and reliability.

Strict Quality Control

Adheres to rigorous quality control processes to deliver top-tier products.

Technical Expertise

Provides expert guidance and support for selecting the right spectacle blind flange.

The main purpose of a spectacle blind flange is to isolate a section of the piping system for maintenance, inspection, or safety purposes. The solid disc blocks flow, while the perforated disc allows flow when required.

A regular blind flange is a solid disc used to seal off the end of a pipe, while a spectacle blind flange consists of two discs (solid and perforated) that can either isolate or allow flow in a piping system depending on the configuration.

Spectacle blind flanges provide a cost-effective and efficient way to isolate or allow flow in a piping system. They are reusable, reduce downtime, and eliminate the need for additional maintenance work, making them ideal for temporary or periodic shutdowns.