ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43 Long Radius Bend Manufacturers

A Long Radius Pipe Bends is a critical component in piping systems, designed to facilitate smooth directional changes while minimizing pressure drop and turbulence. Characterized by its large bending radius—typically 1.5 times the pipe's diameter—this bend ensures an efficient flow of fluids, gases, or slurries. Its seamless curvature reduces stress and wear, making it ideal for high-pressure or high-temperature applications across industries such as oil and gas, petrochemical, power generation, and water treatment. Crafted from materials like carbon steel, stainless steel, or alloys, long radius pipe bends offer excellent durability and corrosion resistance, ensuring reliability in demanding environments.

Ample Alloys is a trusted manufacturer and supplier, known for its expertise in delivering high-quality piping solutions worldwide. The company emphasizes precision engineering and superior craftsmanship, ensuring every product meets the highest standards of quality and performance. With a strong commitment to innovation and customer satisfaction, We provides tailored solutions to meet the unique needs of its clients. Its dedication to excellence and reliability has established it as a preferred choice across various industries.

High-Quality Long Radius Bends, Seamless Long Radius Bends, Custom Long Radius Bends, Precision Engineered Pipe Bends, Durable Long Radius Bends, Pipe Bend with 1.5D Radius, High-Pressure Pipe Bends, 1.5D Long Radius Pipe Bends, Long Radius Bends for Oil and Gas

Long Radius Bends Specifications

Size Range

1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Wall Thickness

Sch 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, XS, 100, 120, 140, 160, Sch XXS

Stainless Steel

ASTM A403 WP 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME B16.9, ASME B16.28, MSS SP-43, MSS SP-75, ASTM A234, ASTM A403, DIN 2605, 2615, 2616, 2617, 10253.

Type / Form

1.5D, 3D, 5D, Seamless, Welded Pipe Bends.

Alloy Steel

ASTM A234, WP1, WP5, WP9, WP11, WP22, WP91, etc.

Bending Radius

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Carbon Steel

ASTM A234, A420, MSS-SP-75, WPB, WPL3, WPL6, WPHY 42, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

Duplex & Super Duplex

ASTM A815 / A815M, UNS S31803 / 2205, UNS S32205, UNS S32101 / LDX 2101, UNS S32750 / 2507, UNS S32760, UNS S32550 / Ferralium 255.

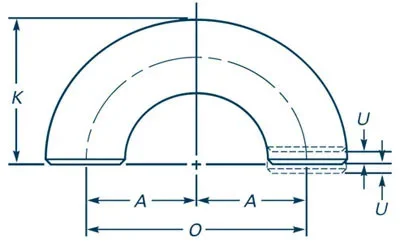

180 Degree Long Radius Pipe Bends Dimensions

| Nominal Pipe Size | Outside Diameter at Bevel | Center to Center, O | Back To Face, K |

|---|---|---|---|

| 1/2 | 21.3 | 76 | 48 |

| 3/4 | 26.7 | 76 | 51 |

| 1 | 33.4 | 76 | 56 |

| 1 1/4 | 42.2 | 95 | 70 |

| 1 1/2 | 48.3 | 114 | 83 |

| 2 | 60.3 | 152 | 106 |

| 2 1/2 | 73 | 190 | 132 |

| 3 | 88.9 | 229 | 159 |

| 3 1/2 | 101.6 | 267 | 184 |

| 4 | 114.3 | 305 | 210 |

| 5 | 141.3 | 381 | 262 |

| 6 | 168.3 | 457 | 313 |

| 8 | 219.1 | 610 | 414 |

| 10 | 273 | 762 | 518 |

| 12 | 323.8 | 914 | 619 |

| 14 | 355.6 | 1067 | 711 |

| 16 | 406.4 | 1219 | 813 |

| 18 | 457 | 1372 | 914 |

| 20 | 508 | 1524 | 1016 |

| 22 | 559 | 1676 | 1118 |

| 24 | 610 | 1829 | 1219 |

Long Radius Pipe Bends Standard Sizes

| Nominal Pipe Size |

Outside Diameter |

Inside Diameter |

Wall Thickness |

Center To End |

Pipe Schedule |

Weight Pounds |

|---|---|---|---|---|---|---|

| 1/2 | 0.84 | 0.622 | 0.109 | 1.5 | 40 | 0.16 |

| 3/4 | 1.05 | 0.824 | 0.113 | 1.5 | 40 | 0.17 |

| 1 | 1.32 | 1.049 | 0.133 | 1.5 | 40 | 0.4 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 1.88 | 40 | 0.55 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 2.25 | 40 | 0.8 |

| 2 | 2.38 | 2.07 | 0.154 | 3 | 40 | 1.6 |

| 2 1/2 | 2.88 | 2.47 | 0.203 | 3.75 | 40 | 3.2 |

| 3 | 3.5 | 3.07 | 0.216 | 4.5 | 40 | 4.8 |

| 3 1/2 | 4 | 3.55 | 0.226 | 5.25 | 40 | 6.6 |

| 4 | 4.5 | 4.03 | 0.237 | 6 | 40 | 8.9 |

| 5 | 5.56 | 5.05 | 0.258 | 7.5 | 40 | 15.1 |

| 6 | 6.62 | 6.07 | 0.28 | 9 | 40 | 24 |

| 8 | 8.62 | 7.98 | 0.322 | 12 | 40 | 47.8 |

| 10 | 10.75 | 10.02 | 0.365 | 15 | 40 | 83.4 |

| 12 | 12.75 | 12 | 0.375 | 18 | * | 123 |

| 14 | 14 | 13.25 | 0.375 | 21 | 30 | 155 |

| 16 | 16 | 15.25 | 0.375 | 24 | 30 | 206 |

| 18 | 18 | 17.25 | 0.375 | 27 | * | 262 |

| 20 | 20 | 19.25 | 0.375 | 30 | 20 | 324 |

| 24 | 24 | 23.25 | 0.375 | 36 | 20 | 466 |

| 30 | 30 | 29.25 | 0.375 | 45 | * | 720 |

| 36 | 36 | 35.25 | 0.375 | 54 | * | 1,039 |

| 42 | 42 | 41.25 | 0.375 | 63 | * | 1,420 |

| 48 | 48 | 47.25 | 0.375 | 72 | * | 2,000 |

Long Radius Pipe Bends Extra Strong Sizes

| Nominal Pipe Size |

Outside Diameter |

Inside Diameter |

Wall Thickness |

Center To End |

Pipe Schedule |

Weight Pounds |

|---|---|---|---|---|---|---|

| 1/2 | 0.84 | 0.546 | 0.147 | 1.5 | 80 | 0.26 |

| 3/4 | 1.05 | 0.742 | 0.154 | 1.5 | 80 | 0.29 |

| 1 | 1.32 | 0.957 | 0.179 | 1.5 | 80 | 0.48 |

| 1 1/4 | 1.66 | 1.27 | 0.191 | 1.88 | 80 | 0.79 |

| 1 1/2 | 1.9 | 1.5 | 0.2 | 2.25 | 80 | 1.2 |

| 2 | 2.37 | 1.93 | 0.218 | 3 | 80 | 2.1 |

| 2 1/2 | 2.88 | 2.32 | 0.276 | 3.75 | 80 | 3.8 |

| 3 | 3.5 | 2.9 | 0.3 | 4.5 | 80 | 6.3 |

| 3 1/2 | 4 | 3.36 | 0.318 | 5.25 | 80 | 8.6 |

| 4 | 4.5 | 3.82 | 0.337 | 6 | 80 | 12.5 |

| 5 | 5.56 | 4.81 | 0.375 | 7.5 | 80 | 21.2 |

| 6 | 6.63 | 5.76 | 0.432 | 9 | 80 | 34.4 |

| 8 | 8.63 | 7.63 | 0.5 | 12 | 80 | 71.3 |

| 10 | 10.75 | 9.75 | 0.5 | 15 | 60 | 111 |

| 12 | 12.75 | 11.75 | 0.5 | 18 | * | 158 |

| 14 | 14 | 13 | 0.5 | 21 | * | 201 |

| 16 | 16 | 15 | 0.5 | 24 | 40 | 270 |

| 18 | 18 | 17 | 0.5 | 27 | * | 348 |

| 20 | 20 | 19 | 0.5 | 30 | 30 | 422 |

| 24 | 24 | 23 | 0.5 | 36 | * | 604 |

| 30 | 30 | 29 | 0.5 | 45 | 20 | 997 |

| 36 | 36 | 35 | 0.5 | 54 | 20 | 1,380 |

| 42 | 42 | 41 | 0.5 | 63 | * | 1,880 |

| 48 | 48 | 47 | 0.5 | 72 | * | 2,502 |

Buttweld Long Radius Bends - Standard Specifications

Long radius bends are a crucial component of industrial piping systems, designed to change direction with minimal disruption to flow characteristics. Adhering to standards such as ASME B16.9 and ASTM A234, these bends ensure reliability, strength, and performance in a wide range of industries.

- ASME Standards:

- ASME B16.9: Factory-Made Wrought Buttwelding Fittings.

- ASME B16.25: Buttwelding Ends (preparation of ends for welding).

- ASME Standards: Wrought Steel Buttwelding Short Radius Elbows and Returns.

- ASTM Standards:

- ASTM A234: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service.

- ASTM A403: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings.

- ASTM A815: Standard Specification for Wrought Ferritic, Ferritic/Austenitic (Duplex), and Martensitic Stainless Steel Piping Fittings.

- ASTM A860: Standard Specification for High-Strength Low-Alloy Welded Fittings (commonly used in pipelines with high strength requirements).

- API Standards:

- API 5L: Specification for Line Pipe (not directly for fittings but related to pipe material in oil and gas industries).

- API 6A: Specification for Wellhead and Christmas Tree Equipment (covers piping components but specific to high-pressure environments in oil fields).

- MSS (Manufacturers Standardization Society) Standards:

- MSS SP-43: Wrought and Fabricated Butt-Welding Fittings for Low-Pressure, Corrosion Resistant Applications (commonly used for stainless steel in low-pressure applications).

- MSS SP-75: Specification for High-Strength Wrought, Butt-Welding Fittings (used in oil and gas for high-strength requirements).

- MSS SP-79: Socket-Welding Reducer Inserts.

- MSS SP-83: Carbon Steel Pipe Unions, Socket Welding, and Threaded.

- DIN (Deutsches Institut für Normung) Standards (European):

- DIN 2605: Steel Elbows for Butt Welding (elbows dimensions and tolerances).

- DIN 2615: Tees for Butt Welding.

- DIN 2616: Reducers for Butt Welding.

- DIN 2617: Caps for Butt Welding.

- EN (European Norms) Standards:

- EN 10253-1: Butt-Welding Pipe Fittings Made of Non-Alloy and Alloy Steels.

- EN 10253-2: Butt-Welding Pipe Fittings with Specified Elevated Temperature Properties.

- EN 10253-3: Butt-Welding Pipe Fittings Made of Austenitic and Austenitic-Ferritic (Duplex) Stainless Steel.

- EN 10253-4: Butt-Welding Pipe Fittings for Low-Pressure Applications.

- JIS (Japanese Industrial Standards):

- JIS B2311: Steel Pipe Fittings for Butt-Welding.

- JIS B2312: Cast Iron Pipe Fittings for Butt-Welding.

- JIS B2313: Malleable Iron Pipe Fittings for Butt-Welding.

- ISO (International Standards Organization) Standards:

- ISO 5251: Specifications for Butt-Welding Ends for Steel Pipe Fittings (compatible with ISO pipes and equipment globally).

- ISO 15590: Petroleum and Natural Gas Industries — Induction Bends, Fittings, and Flanges for Pipeline Transportation Systems.

- BS (British Standards):

- BS 1640: Steel Butt-Welding Pipe Fittings for the Petroleum Industry.

- BS 3799: Forged Fittings, Screwed, and Socket-Welding for the Petroleum Industry

Why Ample Alloys for Long Radius Pipe Bend!

Ample Alloys stands out as a trusted manufacturer and supplier of high-quality long radius pipe bends, offering several compelling reasons to choose them for your piping needs:

100% Satisfaction Guarantee

Experience peace of mind with our 100% Satisfaction Guarantee, ensuring top-quality products and services that exceed your expectations.

Quality Control System

Ensuring excellence through a rigorous Quality Control System that meets the highest industry standards.

Highly Professional Staff

Backed by a team of highly professional staff, we deliver exceptional service and expertise to meet your industry needs.

Accurate Testing Processes

Utilizing precise and accurate testing processes to ensure the highest quality and compliance with industry standards.

The primary difference is the bend radius. A long radius bend has a radius of 1.5 times the pipe diameter (1.5D), while a short radius bend has a radius equal to the pipe diameter (1D). Long radius bends are preferred for reducing pressure drop and maintaining efficient flow.

Long radius pipe bends are commonly used in industries such as oil and gas, petrochemical, power generation, HVAC, and water treatment to redirect fluid flow efficiently and minimize flow disturbances.

The standard bend angles for long radius bends are typically 45°, 90°, and 180°. However, custom angles can be provided based on the needs of the piping system.