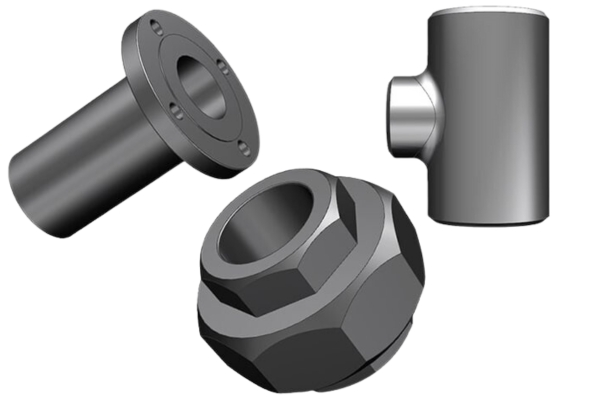

Carbon Steel Forged Socket weld, Threaded Fittings, Carbon Steel Flange

Carbon Steel Pipe Fittings are integral components in piping systems, designed to connect, change direction, reduce size, or terminate the flow of fluids or gases. Renowned for strength, durability, and cost-effectiveness, these fittings are widely used in industries such as oil and gas, petrochemical, power generation, construction, and shipbuilding. Available in various grades like ASTM A234 WPB, WPC, and WP11, they offer excellent performance under high-pressure and high-temperature conditions. Carbon steel fittings come in diverse types, including elbows, tees, reducers, caps, and flanges, with options for seamless and welded construction. Their adaptability to different applications and compliance with international standards ensure their reliability in critical operations.

Carbon Steel Flange is a key component in piping systems, designed to connect pipes, valves, pumps, and other equipment to form a secure, durable joint. Made from high-quality carbon steel, these flanges offer excellent mechanical strength, toughness, and resistance to wear, making them ideal for high-pressure and high-temperature applications. carbon steel flanges are valued for their reliability and cost-effectiveness. They are available in various types, including weld neck, slip-on, blind, threaded, and lap joint, to suit different piping configurations. Manufactured to meet global standards like ASME, ASTM, and DIN, carbon steel flanges ensure compatibility, durability, and superior performance in demanding environments.

Ample Alloys is a trusted name in the metal industry, specializing in the supply of high-quality alloys and metals for a wide range of industrial applications. Known for precision and durability, our products serve key sectors such as aerospace, automotive, energy, and construction.

Carbon Steel Buttweld Fittings, Seamless, Welded Pipe Fittings, A234 WPB Pipe Fittings, Carbon Steel Elbows, Tees, Reducers, End Caps, ASTM A105 Carbon Steel Flanges, Carbon Steel Weld Neck, Slip On, Blind, Socket Weld, Threaded, Lap Joint Flanges, High-Pressure Flanges, A105 Forged Fittings, Carbon Steel Elbows (90° and 45°), Carbon Steel Tees, CS Couplings (Full and Half), Carbon Steel Unions, BSP and NPT Threaded Fittings, Class 3000/6000/9000 Carbon Steel Fittings

ASTM A234 Pipe Fittings Specifications

Size Range

Seamless Fittings: 1/2" - 24"

Welded Fittings: 4" - 72"

Standards / Dimension

ASTM A234, ASME SA234, ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10

Schedule

Schedule 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS

A105 Carbon Steel Flange Specifications

Size Range

1/2″ (15 NB) to 48″ (1200NB)

Standards / Dimension

ASTM A105/ ASME SA105, ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API-605, ASA, AWWA, Custom Drawings

Pressure Rating

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

| Standard | Fittings (ASTM A234 WPB, WPW) | Flanges (ASTM A105, A105N) |

|---|---|---|

| ASTM | A234 WPB, A234 WPC | A105, A105N |

| ASME | SA234 WPB, SA234 WPC | SA105, SA105N |

| DIN | 1.0460 (St 37.2) | C22.8 |

| EN | P235GH, P265GH | C22.8 (EN 10222-2) |

| JIS | G3454 STPG370 | SF440 |

| GOST | 20, 20K | 20G, 09G2S |

| BS | 161 Gr.430 | 161 Gr.430A |

| ISO | ISO 2604-2 Gr.235 | ISO 7005-1 C22.8 |

| Material Grade | Chemical Composition |

|---|---|

| ASTM A234 WPB | Carbon (C): 0.26% max |

| ASTM A105 | Carbon (C): 0.35% max |

| ASTM A350 LF2 | Carbon (C): 0.26% max |

| ASTM A694 F52 | Carbon (C): 0.26% max |

| Material Grade | Tensile Strength | Yield Strength | Elongation | Hardness | Impact Toughness |

|---|---|---|---|---|---|

| ASTM A234 WPB | 70-100 ksi (485-690 MPa) | 30-50 ksi (205-345 MPa) | 20% min (for thickness up to 1/2") | Brinell 140-200 (HB) | 20 ft-lbs @ -20°F (-29°C) |

| ASTM A105 | 70-100 ksi (485-690 MPa) | 30-50 ksi (205-345 MPa) | 20% min (for thickness up to 1/2") | Brinell 140-200 (HB) | Notched Bar Impact: 20 ft-lbs at -20°F (-29°C) |

| ASTM A350 LF2 | 70-90 ksi (485-620 MPa) | 30-50 ksi (205-345 MPa) | 20% min (for thickness up to 1/2") | Brinell 140-200 (HB) | 20 ft-lbs @ -50°F (-45°C) |

| ASTM A694 F52 | 70-90 ksi (485-620 MPa) | 52 ksi (355 MPa) | 20% min (for thickness up to 1/2") | Brinell 170-210 (HB) | 40 ft-lbs @ -50°F (-45°C) |

Available Products of Carbon Steel Buttweld Fittings

Carbon Steel Tee

Carbon Steel Reducer

Carbon Steel Cross

Carbon Steel Stub End

Available Products of Carbon Steel Forged Fittings

Carbon Steel Socket Weld & Thredaed Tee

Carbon Steel Socket Weld & Thredaed Coupling

Carbon Steel Socket Weld & Thredaed Cap

Carbon Steel Socket Weld & Thredaed Boss

Carbon Steel Socket Weld & Thredaed Nipple

Carbon Steel Socket Weld & Thredaed Plug

Available Products of Carbon Steel Flanges

Why Trust Ample Carbons for Your Carbon Steel Fittings Needs!

With a focus on customer satisfaction, on-time delivery, and competitive pricing, Ample Alloys is your go-to partner for all your carbon steel fitting needs.

Exceptional Quality Assurance

Ample Alloys ensures that each carbon steel fitting undergoes strict quality checks to meet or exceed industry standards for strength, durability, and reliability.

Comprehensive Product Range

Our extensive collection of carbon steel fittings, flanges, and forged fittings serves a broad spectrum of applications, from industrial plants to complex pipeline systems.

Tailored Solutions

We specialize in providing customized carbon steel fittings to accommodate unique project requirements, including special sizes, designs, and material specifications.

Strong Customer Relationships

We take pride in building long-term partnerships with our clients, offering personalized support and ensuring that their needs are met with the highest standards.

Carbon steel flanges are used to connect pipes, valves, pumps, and other equipment in a piping system. They create a secure, leak-proof connection between components and are often used in high-pressure and high-temperature systems.

Pipe fittings are used to connect or redirect pipes in a system, while flanges are used to connect piping to valves, pumps, or other piping sections. Fittings typically provide directional changes, while flanges ensure secure connections at system joints.

Common grades for carbon steel fittings and flanges include ASTM A105 (for flanges), ASTM A234 WPB (for fittings), and ASTM A350 LF2 (for low-temperature applications). These grades provide a balance of strength, toughness, and corrosion resistance.