Manufacturer of Forged Adapter Pipe Fittings| MSS SP-79, 83, 95, 97, BS 3799

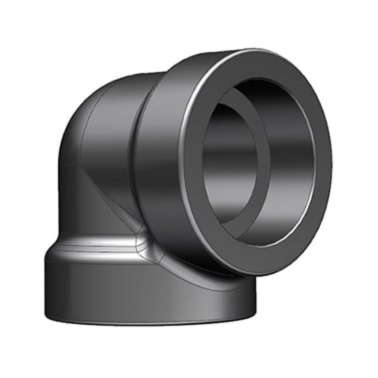

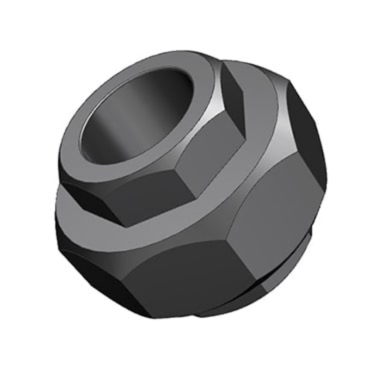

A Forged Adapter is a high-quality pipe fitting used to connect different types of pipes or fittings with varying sizes, materials, or threading. Forged adapters are made by shaping metal under high pressure, making them exceptionally durable and resistant to stress, pressure, and high temperatures. To use a forged adapter, it's essential to choose the correct size, material, and threading type to match the system requirements. These adapters are typically threaded or welded into place, ensuring a secure and leak-proof connection. Whether you're reducing or expanding pipe size, or connecting different pipe types, forged adapters offer a versatile and reliable solution, ensuring the longevity and safety of your piping systems.

Ample Alloys is committed to providing outstanding customer service. Their team of experts is always available to offer technical support, help with product selection, and ensure that your project requirements are met to the highest standards. For threaded adapters that combine strength, reliability, and precision, Ample Alloys is the name you can trust. Whether it's a standard or custom requirement, products are engineered to deliver long-lasting performance in even the most demanding applications.

Premium Threaded pipe adapter, Stainless steel, Carbon Steel, Alloy Steel forged adapter, Forged male adapter, Forged female adapter, Forged hydraulic adapter, Forged reducer adapter, Precision forged adapter, Corrosion-resistant forged adapter Fittings

ASME B16.11 Threaded Adapters Specifications

Size Range

1/8″~4″ (DN6~DN100)

Form

Threaded Adapters, Socket Weld Adapters, Reducing Forged Adapters

Stainless Steel

ASTM A182 & ASME SA182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Carbon Steel

ASTM A105, ASME SA105, A105N, ASTM A350 LF2, ASME SA350, ASTM A694, ASME SA694

Alloy Steel

ASTM A182 & ASME SA182 - F1, F5, F9, F11, F12, F22, F91

Pressure Class

2000LBS, 3000LBS, 6000LBS, 9000LBS

Type

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, 2507.

ASME B16.11 Forged Adapter Dimensions

Threaded Adapter - Forged Fittings Standards

Threaded adapters are a type of forged fitting used to connect pipes or fittings with threaded ends. These fittings follow various international standards to ensure high performance, quality, and compatibility with different piping systems. The key forged fitting standards for threaded adapters are:

- ASME Standards (American Standards):

- ASME B16.11: Covers forged fittings such as socket weld and threaded fittings for high-pressure applications.

- ASTM A105: Specifies carbon steel forgings for piping components.

- ASTM A182: Standard for forged or rolled alloy and stainless steel materials for high-temperature service.

- ASTM A350: Covers low-alloy and carbon steel forgings for low-temperature applications.

- MSS-SP-79: Socket weld fittings with enhanced dimensions and tolerances.

- MSS-SP-83: Threaded and socket weld unions for the petroleum industry.

- EN (European Standards):

- EN 10222: Forged steel fittings for pressure purposes.

- EN 10241: Steel threaded pipe fittings for the European market.

- EN ISO 17292: Specifications for fittings used in valve systems.

- JIS (Japanese Standards) :

- JIS B2316: Covers forged steel pipe fittings such as elbows, tees, and reducers.

- JIS G3454/G3455: Pressure-resistant pipe materials for fittings.

- International Standards:

- DIN 2605: German standard for forged fittings, particularly elbows.

- BS 3799: British standard for forged pipe fittings in threaded and socket weld types.

- GOST 17375: Russian standard for forged fittings used in high-pressure piping.

- Common Testing Standards:

- ASME B31.3: Testing requirements for process piping.

- NACE MR0175/ISO 15156: Compliance for materials in sour gas environments.

- API 598: Valve and fitting inspection standards.

Why Ample Alloys For Forged Adapters!

When it comes to forged adapters, We are trusted and reliable name, offering exceptional products that meet the highest industry standards.

Superior Quality and Material Excellence

Ample Alloys ensures that each forged adapter is made from the highest quality materials, including carbon steel, stainless steel, alloy steel, and other specialized alloys.

Precision Manufacturing

The manufacturing process at Ample Alloys involves advanced forging techniques, ensuring that every forged adapter is produced with precision and accuracy.

Customization and Versatility

Ample Alloys offers customization options for forged adapters to meet the unique requirements of your piping system. Whether you need different sizes, materials, or specific threading types.

Expert Technical Support

Ample Alloys’ team of technical experts is always available to offer assistance, whether you need help selecting the right forged adapter or need guidance on installation and maintenance.

- Threaded forged adapters: Used for screw connections between pipes.

- Socket weld forged adapters: Designed for high-pressure systems, where the adapter fits inside the pipe.

- Flanged forged adapters: Have flanged ends for bolted connections.

- Butt weld forged adapters: Used for seamless connections with welded pipes.

- Reducing forged adapters: Allow connections between pipes of different diameters.

- Strength and durability: The forging process strengthens the material, providing a more reliable and robust connection.

- High-pressure and high-temperature resistance: Forged adapters are ideal for extreme conditions, ensuring safety and long-term performance.

- Leak-proof performance: The precise manufacturing of forged adapters ensures a tight seal, reducing the risk of leaks.

- Versatility: They can be customized to meet specific connection requirements and are used in various industries such as oil and gas, chemical, and power generation.

Yes, forged adapters are versatile and can be used for both temporary and permanent installations. However, in critical systems requiring permanent connections, welded or flanged forged adapters are often preferred due to their higher strength and leak-proof qualities.