Alloy Steel Pipe Fittings, Socket weld, Threaded Fittings, Alloy Steel Flange

Alloy steel pipe fittings are essential components used in a variety of industrial applications, offering strength, durability, and resistance to high temperatures and pressure. Made from high-quality alloy steel, these fittings are designed to withstand extreme conditions, Common types of alloy steel pipe fittings include elbows, tees, reducers, and flanges, each available in various grades like ASTM A234 WP11, WP22, WP91, and A182 F11, to meet specific performance requirements. Alloy steel fittings are known for their ability to handle corrosive environments, high-stress operations, and challenging temperatures, making ideal for critical systems that require high reliability and performance. Whether for welded, threaded, or socket weld connections, alloy steel pipe fittings ensure a tight and secure fit, contributing to the overall integrity of the piping system.

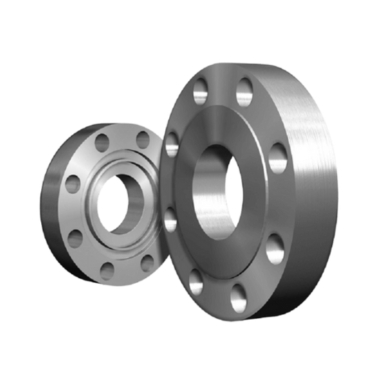

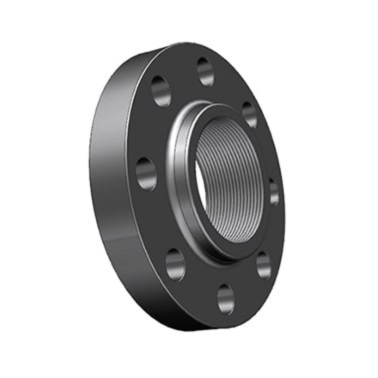

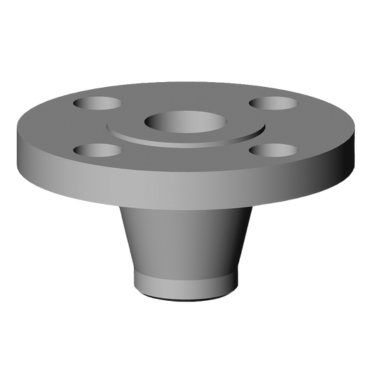

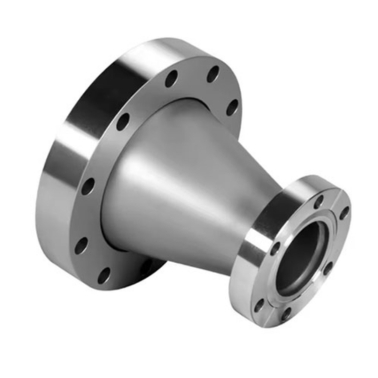

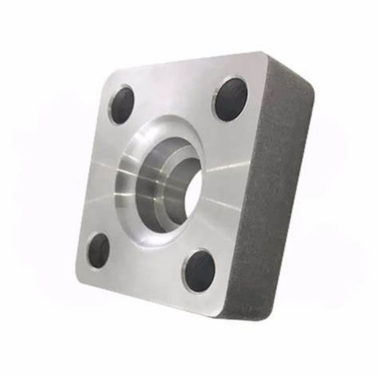

Alloy steel flanges are strong, durable components used to connect pipes and equipment in high-pressure, high-temperature environments. Made from high-quality alloy steel, they offer excellent resistance to corrosion and stress, making them ideal for industries like oil and gas, chemical processing, and power generation. Available in various grades such as ASTM A182 F1, F5, F9, F11, F12, F22, F91, alloy steel flanges provide secure, reliable connections for critical piping systems.

Ample Alloys follows a commitment to delivering high-quality alloy steel products, ensuring precision, durability, and reliability. Our prioritize customer satisfaction by adhering to strict manufacturing standards and providing consistent, top-tier solutions.

Alloy Steel A234 WP11, WP22 Pipe Fittings, A182 F11 Alloy Steel Flanges, A182 F22 SORF Flange, A234 WP11 Butt Weld Fittings, A182 F91 Socket Weld Fittings, Threaded Fittings, A182 F5 Forged Fittings, A234 WP9 Elbows, A234 WP91 Tees, A234 WP22 Alloy Steel Reducers, High-Pressure A182 F92 Fittings, High-Temperature Alloy Steel Fittings A182 F9, A234 WP11 Caps, A234 WP3 Fittings, ASTM A234 WP12 Cross

A234 Alloy Steel Pipe Fittings Specifications

Size Range

Seamless Fittings: 1/2" - 24"

Welded Fittings: 4" - 72"

Standards / Dimension

ASTM A234, ASME SA234, ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10

Schedule

Schedule 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS

A182 Alloy Steel Flange Specifications

Size Range

1/2″ (15 NB) to 48″ (1200NB)

Standards / Dimension

ASTM A182/ ASME SA182, ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API-605, ASA, AWWA, Custom Drawings

Pressure Rating

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

| Standard | Grade | Equivalent Grades |

|---|---|---|

| ASTM A182 | F1 | DIN 1.5415, EN 15Mo3, JIS SFVC1 |

| ASTM A182 | F2 | DIN 1.7383, EN X20CrMoV11-1, JIS SCMV2 |

| ASTM A182 | F5 | DIN 1.7362, EN X12CrMo5, JIS SCMV5 |

| ASTM A182 | F9 | DIN 1.7386, EN X12CrMo9-1, JIS SCMV9 |

| ASTM A182 | F11 | DIN 1.7335, EN X12CrMo5, JIS SCMV3 |

| ASTM A182 | F12 | DIN 1.7383, EN X20CrMoV11-1, JIS SCMV12 |

| ASTM A182 | F22 | DIN 1.7380, EN X12CrMo9-1, JIS SCMV4 |

| ASTM A182 | F91 | DIN 1.4903, EN X10CrMoVNb9-1, JIS SCMV91 |

| ASTM A234 | WP1 | DIN 1.5415, EN 15Mo3, JIS SCPH1 |

| ASTM A234 | WP5 | DIN 1.7362, EN X12CrMo5, JIS SCPH5 |

| ASTM A234 | WP9 | DIN 1.7386, EN X12CrMo9-1, JIS SCPH9 |

| ASTM A234 | WP11 | DIN 1.7335, EN X12CrMo5, JIS SCPH21 |

| ASTM A234 | WP12 | DIN 1.7383, EN X20CrMoV11-1, JIS SCPH12 |

| ASTM A234 | WP22 | DIN 1.7380, EN X12CrMo9-1, JIS SCPH22 |

| ASTM A234 | WP91 | DIN 1.4903, EN X10CrMoVNb9-1, JIS SCP91 |

| Grade | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Molybdenum (Mo) | Others |

|---|---|---|---|---|---|---|---|---|

| ASTM A182 F1 | 0.15 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.10-0.50 | 0.44-0.65 | 0.44-0.65 | - |

| ASTM A182 F5 | 0.15 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.50 max | 4.00-6.00 | 0.44-0.65 | - |

| ASTM A182 F9 | 0.15 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.50 max | 8.00-10.00 | 0.90-1.10 | - |

| ASTM A182 F11 | 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50 max | 1.00-1.50 | 0.44-0.65 | - |

| ASTM A182 F22 | 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50 max | 1.90-2.60 | 0.87-1.13 | - |

| ASTM A182 F91 | 0.08-0.12 | 0.30-0.60 | 0.020 max | 0.010 max | 0.18-0.25 | 8.00-9.50 | 0.85-1.05 | V: 0.18-0.25, N: 0.03-0.07 |

| ASTM A234 WP1 | 0.05-0.20 | 0.30-0.80 | 0.030 max | 0.030 max | 0.10-0.50 | 0.44-0.65 | 0.44-0.65 | - |

| ASTM A234 WP5 | 0.15 max | 0.30-0.60 | 0.030 max | 0.025 max | 0.50 max | 4.00-6.00 | 0.44-0.65 | - |

| ASTM A234 WP9 | 0.15 max | 0.30-0.60 | 0.030 max | 0.025 max | 0.50 max | 8.00-10.00 | 0.90-1.10 | - |

| ASTM A234 WP11 | 0.05-0.15 | 0.30-0.60 | 0.030 max | 0.025 max | 0.50 max | 1.00-1.50 | 0.44-0.65 | - |

| ASTM A234 WP22 | 0.05-0.15 | 0.30-0.60 | 0.030 max | 0.025 max | 0.50 max | 1.90-2.60 | 0.87-1.13 | - |

| ASTM A234 WP91 | 0.08-0.12 | 0.30-0.60 | 0.020 max | 0.010 max | 0.18-0.25 | 8.00-9.50 | 0.85-1.05 | V: 0.18-0.25, N: 0.03-0.07 |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Impact Strength (J) |

|---|---|---|---|---|---|

| ASTM A182 F1 | 415-585 | 205 min | 20 min | 187 max | - |

| ASTM A182 F5 | 415-585 | 205 min | 20 min | 187 max | - |

| ASTM A182 F9 | 415-585 | 205 min | 20 min | 187 max | - |

| ASTM A182 F11 | 485-655 | 275 min | 20 min | 217 max | - |

| ASTM A182 F22 | 485-655 | 275 min | 20 min | 217 max | - |

| ASTM A182 F91 | 585-760 | 415 min | 20 min | 250 max | - |

| ASTM A234 WP1 | 380-515 | 205 min | 20 min | 170 max | - |

| ASTM A234 WP5 | 415-585 | 205 min | 20 min | 187 max | - |

| ASTM A234 WP9 | 415-585 | 205 min | 20 min | 187 max | - |

| ASTM A234 WP11 | 485-655 | 275 min | 20 min | 217 max | - |

| ASTM A234 WP22 | 485-655 | 275 min | 20 min | 217 max | - |

| ASTM A234 WP91 | 585-760 | 415 min | 20 min | 250 max | - |

Available Products of Alloy Steel Buttweld Fittings

Alloy Steel Tee

Alloy Steel Reducer

Alloy Steel Cross

Alloy Steel Stub End

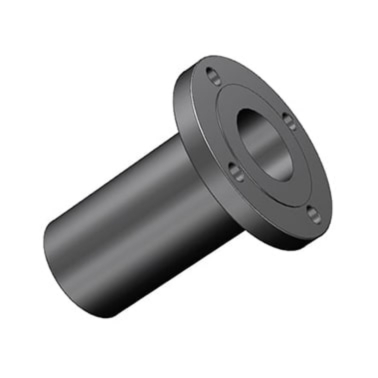

Available Products of Alloy Steel Forged Fittinhgs

Alloy Steel Socket Weld & Thredaed Tee

Alloy Steel Socket Weld & Thredaed Coupling

Alloy Steel Socket Weld & Thredaed Cap

Alloy Steel Socket Weld & Thredaed Boss

Alloy Steel Socket Weld & Thredaed Nipple

Alloy Steel Socket Weld & Thredaed Plug

Available Products of Alloy Steel Flange

Why Trust Ample Alloys for Your Alloy Steel Fittings Needs!

Ample Alloys stands out as a trusted name in the industry for supplying high-quality alloy steel pipe fittings, offering several advantages that make it a preferred choice:

Extensive Product Range

Wide selection of elbows, tees, reducers, caps, and couplings in grades like ASTM A234 WP5, WP9, WP11, WP22, WP91.

Quality Assurance

Durable, corrosion-resistant fittings adhering to ASTM, ASME, DIN, EN, and ISO standards, with rigorous quality checks.

Industry Expertise

Decades of experience serving critical sectors like oil & gas, petrochemicals, and power plants.

Customization

Tailored fittings in seamless and welded types to meet project-specific needs.

- Oil & gas

- Power plants

- Petrochemicals

- Refineries

- Fertilizer plants

- Heat exchangers

Yes, both seamless and welded options are available to suit various applications and pressure requirements.

- Mill Test Reports (MTR)

- Third-party inspection certificates

- Compliance with NACE and ISO standards