Socket Weld & Threaded Boss Fittings| ASME B16.11, MSS SP-79, 83, 95, 97, BS 3799

Socket Weld Boss Fittings are designed to accommodate high-pressure applications, providing a strong, leak-proof connection by welding the pipe into the socket. These fittings are ideal for small to medium-sized pipes and are widely used in industries like oil & gas, chemical processing, and power generation.

Threaded Boss Fittings offer an easy-to-install, threaded connection, making them a great option when welding is not feasible or desired. Threaded boss fittings provide flexibility in maintenance and disassembly, allowing for quick pipe replacements without the need for special equipment. Both types of fittings come in a variety of materials and sizes, offering versatility for different piping needs. Whether you choose Socket Weld Boss or Threaded Boss fittings, they ensure a secure, durable, and long-lasting connection for your piping systems.

Ample Alloys is a trusted supplier of high-quality forged fittings, including Socket Weld and Threaded Boss fittings. With years of experience, we provide durable and reliable products for industries like oil & gas, chemical processing, and power generation. Our forged boss fittings are designed to meet the highest standards, ensuring secure and long-lasting connections for your piping systems. At Ample Alloys, we prioritize customer satisfaction and offer competitive prices, making us a preferred choice for businesses worldwide.

Top-notch Threaded Boss Fittings, Forged Socket Weld Boss Connection, Socket Weld Boss for High Pressure, Threaded Boss for Piping Systems

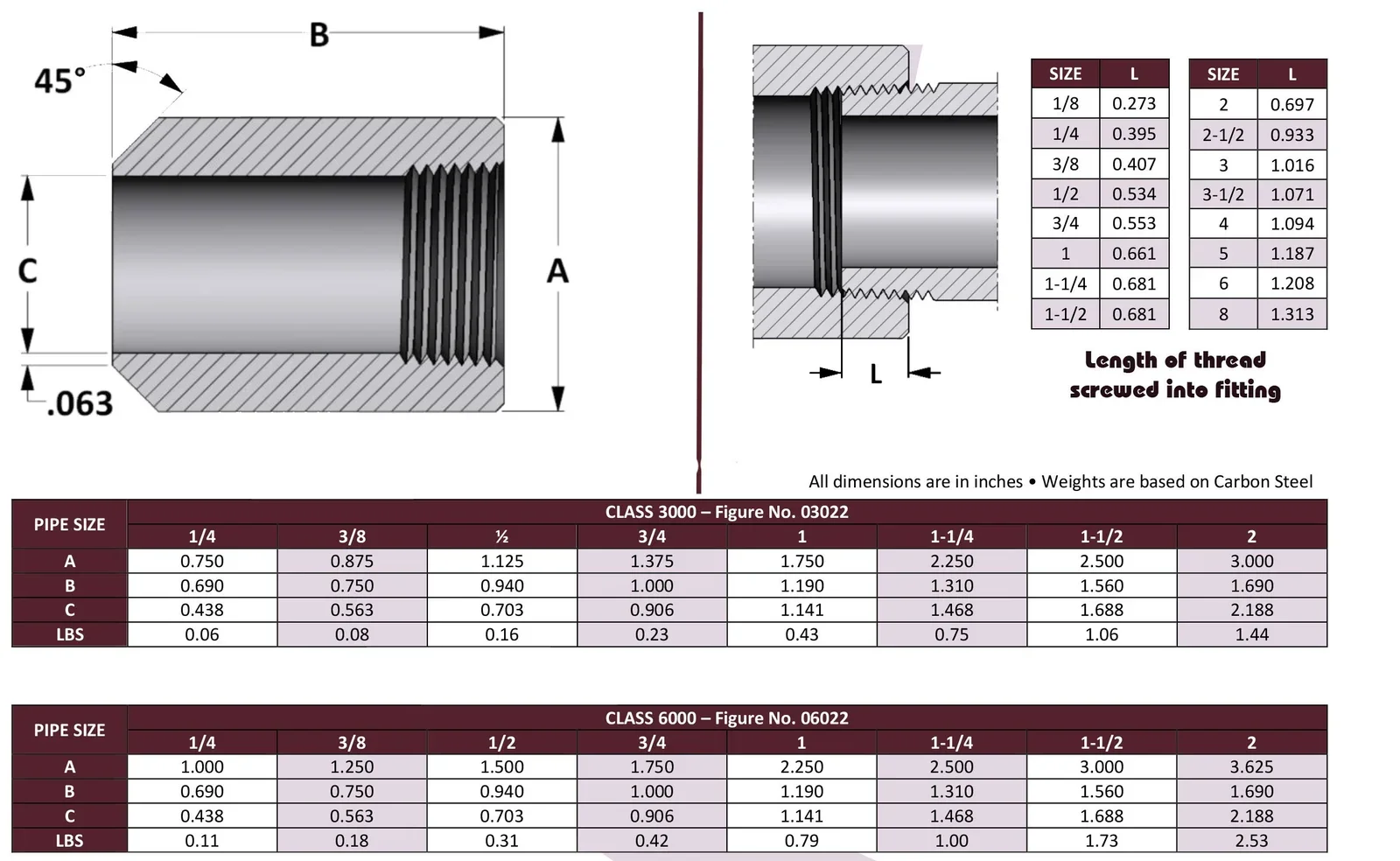

ASME B16.11 Forged Boss Specifications

Size Range

1/8″~4″ (DN6~DN100)

Form

Socket Weld Boss Fittings, Threaded Boss Fittings

Stainless Steel

ASTM A182 & ASME SA182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Carbon Steel

ASTM A105, ASME SA105, A105N, ASTM A350 LF2, ASME SA350, ASTM A694, ASME SA694

Alloy Steel

ASTM A182 & ASME SA182 - F1, F5, F9, F11, F12, F22, F91

Pressure Class

2000LBS, 3000LBS, 6000LBS, 9000LBS

Type

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, 2507.

ASME B16.11 Forged Threaded Boss

Boss - Forged Fittings Standards

These standards guarantee that Boss fittings are produced with precise dimensions and material properties, making them reliable for critical applications in industries such as oil and gas, chemical processing, and power generation. They ensure that the fittings maintain their structural integrity under high pressure and thermal conditions.

- ASME Standards (American Standards):

- ASME B16.11: Covers forged fittings such as socket weld and threaded fittings for high-pressure applications.

- ASTM A105: Specifies carbon steel forgings for piping components.

- ASTM A182: Standard for forged or rolled alloy and stainless steel materials for high-temperature service.

- ASTM A350: Covers low-alloy and carbon steel forgings for low-temperature applications.

- MSS-SP-79: Socket weld fittings with enhanced dimensions and tolerances.

- MSS-SP-83: Threaded and socket weld unions for the petroleum industry.

- EN (European Standards):

- EN 10222: Forged steel fittings for pressure purposes.

- EN 10241: Steel threaded pipe fittings for the European market.

- EN ISO 17292: Specifications for fittings used in valve systems.

- JIS (Japanese Standards) :

- JIS B2316: Covers forged steel pipe fittings such as elbows, tees, and reducers.

- JIS G3454/G3455: Pressure-resistant pipe materials for fittings.

- International Standards:

- DIN 2605: German standard for forged fittings, particularly elbows.

- BS 3799: British standard for forged pipe fittings in threaded and socket weld types.

- GOST 17375: Russian standard for forged fittings used in high-pressure piping.

- Common Testing Standards:

- ASME B31.3: Testing requirements for process piping.

- NACE MR0175/ISO 15156: Compliance for materials in sour gas environments.

- API 598: Valve and fitting inspection standards.

Why Ample Alloys For Forged Boss!

Ample Alloys stands out as a trusted supplier of Socket Weld and Threaded Boss fittings due to our commitment to quality, precision, and customer satisfaction.

Premium Quality Materials

We source only the finest materials to ensure that our forged boss fittings meet the highest industry standards. Our products are made from durable and corrosion-resistant materials, offering reliability in harsh environments.

Strict Adherence to Standards

All our Socket Weld and Threaded Boss fittings are manufactured in compliance with international standards such as ASME B16.11, ensuring they meet performance and safety requirements for a wide range of applications.

Competitive Pricing

We provide high-quality forged fittings at competitive prices, ensuring that you get the best value for your investment without compromising on performance or safety.

Timely Delivery

With a strong global supply chain, we guarantee on-time delivery of forged boss fittings, helping you maintain smooth project timelines and operations.

Socket Weld and Threaded Boss fittings are widely used in industries such as oil & gas, chemical processing, power generation, and water treatment systems due to their strength and reliability under high-pressure conditions.

- Socket Weld Boss Fittings are welded to the pipe, creating a strong, leak-proof connection.

- Threaded Boss Fittings have threaded connections that can be easily installed and removed, making them ideal for applications where welding is not feasible.

Yes, Socket Weld and Threaded Boss fittings can be used in high-temperature environments, depending on the material grade. Stainless steel and alloy steel versions are ideal for such applications due to their ability to withstand extreme temperatures.