Buttweld Long & Short Radius 90° Elbow | ASME/ANSI B16.9, B16.28, MSS-SP-43

A 90-degree elbow is a crucial pipe fitting designed to change the direction of a piping system by 90 degrees. Widely used in various industries, these elbows are essential for creating turns in piping systems while maintaining flow efficiency and system integrity. They are available in different materials such as stainless steel, carbon steel, and alloy steel, making them versatile for use in diverse applications.

A Short Radius (SR) 90-Degree Elbow features a compact design with a centerline radius equal to the pipe's diameter, making it ideal for tight spaces where minimal bending radius is required. In contrast, a Long Radius (LR) 90-Degree Elbow has a larger centerline radius, 1.5 times the pipe's diameter, offering smoother flow and reduced pressure loss, making it suitable for systems prioritizing efficiency and minimal turbulence.

Ample Alloys, specialize in providing durable and precision-engineered 90° Pipe Elbows that meet international standards such as ANSI B16.9 and ASME B16.9. These elbows are designed for smooth directional changes in pipelines, ensuring minimal pressure drop and efficient flow management. Whether for high-pressure systems or corrosive environments, our elbows deliver consistent performance.

ANSI B16.9 90 Degree Pipe Fittings Elbow, A403 SS 90 Deg Elbows, High-Quality Carbon, Alloy Steel 90 Deg Elbow, Buttweld 90 Deg. Elbow, Sch 10 90 Degree Elbow, ANSI B16.9 90 Degree Pipe Fittings Elbow

ASME B16.9 90° Pipe Elbow Specifications

Size Range

1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Wall Thickness

Sch 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, XS, 100, 120, 140, 160, Sch XXS

Stainless Steel

ASTM A403 WP 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME B16.9, ASME B16.28, MSS SP-43, MSS SP-75, ASTM A234, ASTM A403, DIN 2605, 2615, 2616, 2617, 10253.

Type / Form

Seamless, Welded, Fabricated / 90 Deg Long Radius Elbow, Short Radius Elbow.

Alloy Steel

ASTM A234, WP1, WP5, WP9, WP11, WP22, WP91, etc.

Bending Radius

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Carbon Steel

ASTM A234, A420, MSS-SP-75, WPB, WPL3, WPL6, WPHY 42, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

Duplex & Super Duplex

ASTM A815 / A815M, UNS S31803 / 2205, UNS S32205, UNS S32101 / LDX 2101, UNS S32750 / 2507, UNS S32760, UNS S32550 / Ferralium 255.

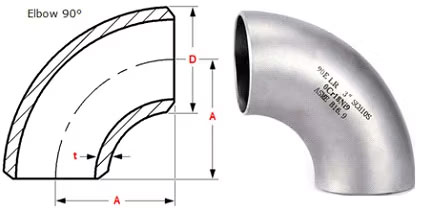

90 degree Elbow Dimensions

| Pipe Size (D) | Radius (A) | Wall Thickness (t) - Schedule 40 | Wall Thickness (t) - Schedule 80 |

|---|---|---|---|

| 1/2" | 0.5D | 0.109" | 0.147" |

| 3/4" | 0.5D | 0.113" | 0.154" |

| 1" | 0.5D | 0.140" | 0.179" |

| 1-1/4" | 0.5D | 0.140" | 0.179" |

| 1-1/2" | 0.75D | 0.145" | 0.191" |

| 2" | 1.0D | 0.154" | 0.218" |

| 2-1/2" | 1.0D | 0.203" | 0.276" |

| 3" | 1.0D | 0.216" | 0.300" |

| 4" | 1.5D | 0.237" | 0.337" |

| 5" | 1.5D | 0.250" | 0.375" |

| 6" | 1.5D | 0.280" | 0.432" |

| 8" | 2.0D | 0.322" | 0.500" |

| 10" | 2.0D | 0.365" | 0.620" |

| 12" | 2.5D | 0.406" | 0.687" |

| 14" | 2.5D | 0.437" | 0.750" |

| 16" | 3.0D | 0.500" | 0.875" |

| 18" | 3.0D | 0.500" | 1.000" |

| 20" | 3.5D | 0.562" | 1.125" |

| 24" | 4.0D | 0.625" | 1.250" |

LR & SR 90° Elbow Tolerance - ASME B16.9

| Dimension | Tolerance |

|---|---|

| Outside Diameter (OD) | ±1% (Minimum ±0.5 mm) |

| Wall Thickness | ±12.5% |

| Angle (45°) | ±1° |

| Center-to-End (A) | ±1.5% (Minimum ±3 mm) |

| Bevel End | ±1° for angle, ±0.5 mm for root face |

Weight Chart of 90 Degree Elbow - ASME B16.9

| NPS Inches |

ELBOWS LR 90° |

ELBOWS SR 90° |

||||||

|---|---|---|---|---|---|---|---|---|

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.90 | 1.20 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 | 0.60 | 0.90 | 1.35 | 1.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 | 0.90 | 1.35 | 2.65 | 3.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.90 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

Common Buttweld 90° Elbow Standards

A comprehensive list of 45° Elbow pipe fittings standards commonly used across industries like Oil & Gas, Petrochemical, Chemical, Power, and Water Treatment. These standards specify requirements for dimensions, materials, testing, and quality assurance.

- ASME Standards:

- ASME B16.9: Factory-Made Wrought Buttwelding Fittings.

- ASME B16.25: Buttwelding Ends (preparation of ends for welding).

- ASME Standards: Wrought Steel Buttwelding Short Radius Elbows and Returns.

- ASTM Standards:

- ASTM A234: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service.

- ASTM A403: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings.

- ASTM A815: Standard Specification for Wrought Ferritic, Ferritic/Austenitic (Duplex), and Martensitic Stainless Steel Piping Fittings.

- ASTM A860: Standard Specification for High-Strength Low-Alloy Welded Fittings (commonly used in pipelines with high strength requirements).

- API Standards:

- API 5L: Specification for Line Pipe (not directly for fittings but related to pipe material in oil and gas industries).

- API 6A: Specification for Wellhead and Christmas Tree Equipment (covers piping components but specific to high-pressure environments in oil fields).

- MSS (Manufacturers Standardization Society) Standards:

- MSS SP-43: Wrought and Fabricated Butt-Welding Fittings for Low-Pressure, Corrosion Resistant Applications (commonly used for stainless steel in low-pressure applications).

- MSS SP-75: Specification for High-Strength Wrought, Butt-Welding Fittings (used in oil and gas for high-strength requirements).

- MSS SP-79: Socket-Welding Reducer Inserts.

- MSS SP-83: Carbon Steel Pipe Unions, Socket Welding, and Threaded.

- DIN (Deutsches Institut für Normung) Standards (European):

- DIN 2605: Steel Elbows for Butt Welding (elbows dimensions and tolerances).

- DIN 2615: Tees for Butt Welding.

- DIN 2616: Reducers for Butt Welding.

- DIN 2617: Caps for Butt Welding.

- EN (European Norms) Standards:

- EN 10253-1: Butt-Welding Pipe Fittings Made of Non-Alloy and Alloy Steels.

- EN 10253-2: Butt-Welding Pipe Fittings with Specified Elevated Temperature Properties.

- EN 10253-3: Butt-Welding Pipe Fittings Made of Austenitic and Austenitic-Ferritic (Duplex) Stainless Steel.

- EN 10253-4: Butt-Welding Pipe Fittings for Low-Pressure Applications.

- JIS (Japanese Industrial Standards):

- JIS B2311: Steel Pipe Fittings for Butt-Welding.

- JIS B2312: Cast Iron Pipe Fittings for Butt-Welding.

- JIS B2313: Malleable Iron Pipe Fittings for Butt-Welding.

- ISO (International Standards Organization) Standards:

- ISO 5251: Specifications for Butt-Welding Ends for Steel Pipe Fittings (compatible with ISO pipes and equipment globally).

- ISO 15590: Petroleum and Natural Gas Industries — Induction Bends, Fittings, and Flanges for Pipeline Transportation Systems.

- BS (British Standards):

- BS 1640: Steel Butt-Welding Pipe Fittings for the Petroleum Industry.

- BS 3799: Forged Fittings, Screwed, and Socket-Welding for the Petroleum Industry

Why Ample Alloys for 90 Degree Elbows!

Ample Alloys stands out as a trusted supplier of high-quality 90-degree elbows, offering precision-engineered solutions for various industries. Choose Ample Alloys for reliable, durable, and high-performance 90-degree elbows tailored to your project requirements!

Quality Control System

Ensuring excellence through a rigorous Quality Control System that meets the highest industry standards.

100% Satisfaction Guarantee

Experience peace of mind with our 100% Satisfaction Guarantee, ensuring top-quality products and services that exceed your expectations.

Highly Professional Staff

Backed by a team of highly professional staff, we deliver exceptional service and expertise to meet your industry needs.

Accurate Testing Processes

Utilizing precise and accurate testing processes to ensure the highest quality and compliance with industry standards.

- Material Compatibility: Ensure the material matches the application's requirements (e.g., corrosion resistance for marine use).

- Schedule Rating: Choose the appropriate schedule based on pressure and flow rate.

- Radius Type: Opt for long radius for smoother flow or short radius for compact installations.

- Certification: Verify compliance with international standards like ANSI B16.9 for quality assurance.

- Efficient Directional Change: Helps in redirecting the flow without significant loss of pressure.

- Durability: Withstands high pressure and temperature conditions due to robust material selection.

- Customizable Options: Available in various sizes, wall thicknesses, and coatings to meet specific project requirements.

- Oil and Gas Industry: For transporting liquids and gases through complex piping networks.

- Chemical Plants: To ensure safe redirection of corrosive or high-temperature substances.

- HVAC Systems: For optimizing airflow in ductwork and ventilation systems.

- Water Treatment: Used in pipelines handling large volumes of water.

- Power Plants: For steam and fluid distribution.