Buttweld 5D Elbow Fittings Manufacturer | ANSI B16.9, ASME B16.28, MSS-SP-43

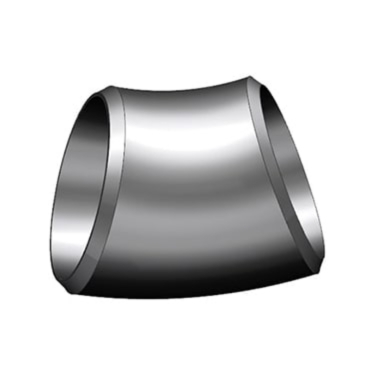

A 5D bend refers to a type of pipe bend where the radius of curvature is five times the nominal diameter (5D) of the pipe. This standard is commonly used in piping systems to achieve smooth directional changes in flow without causing excessive turbulence or pressure loss. The "5D" designation indicates that the centerline radius of the bend is five times the pipe's outer diameter, making it a moderate curve compared to more extreme bends like 3D or 2D.

Buttweld 5D elbows are often chosen for applications where space is limited but where a gentler curve is needed to maintain the integrity and flow efficiency of the pipeline. This radius helps reduce stress on the piping system and improves overall performance, making it a popular choice for industries like oil and gas, petrochemical, and water treatment.

Ample Alloys is an ISO 9001:2015 / ISO 14001:2015 / OHSAS 18000:2007 / PED Certified Manufacturers and Stockist of 5D Elbows We offers you an exquisite customer experience through our considerable product portfolio and a conscious and active customer-friendly team. We engineer products that are feasible and advantageous in a long run. Produce qualitative range of Our offered Stainless Steel 5D Elbow is being developed and designed in accordance by means of the international quality of standards at our infrastructure facility for to attain the highest scales of quality. We are manufacturing ASME B16.9 5D Elbow in both Seamless and Welded, it proudly caters the needs of our customers in Oil & Gas, Power Generation, Petrochemical, and Industrial Construction, inclusive of Upstream, Midstream, and Downstream sectors.

High-quality 5D pipe bend, Stainless steel 5D elbow, ASME B16.9 5D elbow, Seamless 5D bend, Welded 5D elbow, 5D bend fittings, Carbon steel 5D bend, 5D elbow for oil and gas, Long radius 5D elbow, 5D elbow in pipelines, 5D bend for construction projects

Butt weld 5D Bends Specifications

Size Range

1/2” NB TO 36” NB. (Seamless up to 24”), (Welded 8” TO 36”)

Wall Thickness

Sch 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, XS, 100, 120, 140, 160, Sch XXS

Stainless Steel

ASTM A403 WP 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME B16.9, ASME B16.28, MSS SP-43, MSS SP-75, ASTM A234, ASTM A403, DIN 2605, 2615, 2616, 2617, 10253.

Type / Form

Seamless, Welded, Fabricated / 5D Elbow, Bend.

Alloy Steel

ASTM A234, WP1, WP5, WP9, WP11, WP22, WP91, etc.

Bending Radius

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Carbon Steel

ASTM A234, A420, MSS-SP-75, WPB, WPL3, WPL6, WPHY 42, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

Duplex & Super Duplex

ASTM A815 / A815M, UNS S31803 / 2205, UNS S32205, UNS S32101 / LDX 2101, UNS S32750 / 2507, UNS S32760, UNS S32550 / Ferralium 255.

ASME B16.16.9 BW 5D Bend Dimensions

| Size | Wall Thickness | Radius | Approx. Weight (kg) | ||||

|---|---|---|---|---|---|---|---|

| DN | OD | s | a | e |

|||

| inch | mm | mm | mm | mm | mm | 45° | 90° |

| 1 | 25 | 30 | 1.5 | 30 | 12 | 0.03 | 0.05 |

| 1¼ | 32 | 38 | 1.5 | 32.5 | 14 | 0.03 | 0.08 |

| 1½ | 40 | 44.5 | 1.5 | 40 | 17 | 0.06 | 0.14 |

| 2 | 50 | 57 | 1.5 | 52.5 | 22 | 0.10 | 0.20 |

| 2½ | 65 | 76 | 2 | 70 | 29 | 0.23 | 0.46 |

| 3 | 80 | 89 | 2 | 82.5 | 34 | 0.32 | 0.64 |

| 4 | 100 | 108 | 2.5 | 100 | 41 | 0.58 | 1.16 |

| 5 | 125 | 133 | 2.5 | 125 | 52 | 0.90 | 1.80 |

| 6 | 150 | 159 | 2.5 | 150 | 62 | 1.30 | 2.60 |

| 7 | 175 | 194 | 3 | 180 | 75 | 1.90 | 3.80 |

| 8 | 200 | 219 | 3 | 210 | 87 | 3.00 | 6.00 |

| 10 | 250 | 267 | 3 | 255 | 106 | 4.44 | 8.88 |

| 12 | 300 | 324 | 4 | 305 | 126 | 8.55 | 17.10 |

| 14 | 350 | 368 | 4 | 352.5 | 146 | 11.30 | 22.60 |

| 16 | 400 | 419 | 4 | 400 | 166 | 16.40 | 32.80 |

| 18 | 450 | 457 | 4.5 | 457 | 189 | 20.45 | 40.90 |

| 20 | 500 | 508 | 5 | 508 | 210 | 28.10 | 56.20 |

| 24 | 600 | 610 | 5 | 610 | 253 | 40.50 | 81.00 |

| 28 | 700 | 711 | 6 | 711 | 295 | 66.00 | 132.00 |

| 32 | 800 | 813 | 6 | 813 | 337 | 86.50 | 173.00 |

| 36 | 900 | 914 | 8 | 914 | 379 | 145.50 | 291.00 |

Buttweld 5D Elbow Dimension Tolerances

| Parameter | Tolerance |

|---|---|

| Centerline Radius | ±1% of the specified centerline radius |

| Outside Diameter | ±1% of the specified outside diameter |

| Wall Thickness | ±10% of the specified wall thickness |

| End Preparation Length | ±1/16" (1.5 mm) or as per standard specification |

| Angle of Bend | ±2° for standard elbows (except for special designs) |

| Elbow Length | ±1/8" (3 mm) or as per standard specifications |

| Straight Section (between bends) | ±1/4" (6 mm) or as per standard specifications |

Common Buttweld 5D Elbow Standards

Common Buttweld 5D Elbow Standards are specified by several widely accepted industry standards that provide guidelines for the design, dimensions, material specifications, and tolerances of these components. Below are some of the key standards for Buttweld 5D elbows:

- ASME Standards:

- ASME B16.9: Factory-Made Wrought Buttwelding Fittings.

- ASME B16.25: Buttwelding Ends (preparation of ends for welding).

- ASME Standards: Wrought Steel Buttwelding Short Radius Elbows and Returns.

- ASTM Standards:

- ASTM A234: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service.

- ASTM A403: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings.

- ASTM A815: Standard Specification for Wrought Ferritic, Ferritic/Austenitic (Duplex), and Martensitic Stainless Steel Piping Fittings.

- ASTM A860: Standard Specification for High-Strength Low-Alloy Welded Fittings (commonly used in pipelines with high strength requirements).

- API Standards:

- API 5L: Specification for Line Pipe (not directly for fittings but related to pipe material in oil and gas industries).

- API 6A: Specification for Wellhead and Christmas Tree Equipment (covers piping components but specific to high-pressure environments in oil fields).

- MSS (Manufacturers Standardization Society) Standards:

- MSS SP-43: Wrought and Fabricated Butt-Welding Fittings for Low-Pressure, Corrosion Resistant Applications (commonly used for stainless steel in low-pressure applications).

- MSS SP-75: Specification for High-Strength Wrought, Butt-Welding Fittings (used in oil and gas for high-strength requirements).

- MSS SP-79: Socket-Welding Reducer Inserts.

- MSS SP-83: Carbon Steel Pipe Unions, Socket Welding, and Threaded.

- DIN (Deutsches Institut für Normung) Standards (European):

- DIN 2605: Steel Elbows for Butt Welding (elbows dimensions and tolerances).

- DIN 2615: Tees for Butt Welding.

- DIN 2616: Reducers for Butt Welding.

- DIN 2617: Caps for Butt Welding.

- EN (European Norms) Standards:

- EN 10253-1: Butt-Welding Pipe Fittings Made of Non-Alloy and Alloy Steels.

- EN 10253-2: Butt-Welding Pipe Fittings with Specified Elevated Temperature Properties.

- EN 10253-3: Butt-Welding Pipe Fittings Made of Austenitic and Austenitic-Ferritic (Duplex) Stainless Steel.

- EN 10253-4: Butt-Welding Pipe Fittings for Low-Pressure Applications.

- JIS (Japanese Industrial Standards):

- JIS B2311: Steel Pipe Fittings for Butt-Welding.

- JIS B2312: Cast Iron Pipe Fittings for Butt-Welding.

- JIS B2313: Malleable Iron Pipe Fittings for Butt-Welding.

- ISO (International Standards Organization) Standards:

- ISO 5251: Specifications for Butt-Welding Ends for Steel Pipe Fittings (compatible with ISO pipes and equipment globally).

- ISO 15590: Petroleum and Natural Gas Industries — Induction Bends, Fittings, and Flanges for Pipeline Transportation Systems.

- BS (British Standards):

- BS 1640: Steel Butt-Welding Pipe Fittings for the Petroleum Industry.

- BS 3799: Forged Fittings, Screwed, and Socket-Welding for the Petroleum Industry

Why Ample Alloys for 5D Bends!

Ample Alloys stands out as a trusted manufacturer and supplier of high-quality 5D bends, offering several advantages for businesses seeking durable, precision-engineered components. Here’s why Ample Alloys should be your preferred choice for 5D bends:

Advanced Manufacturing Expertise

With state-of-the-art facilities and cutting-edge technology, we produce 3D bends that ensure precision, reliability, and superior performance in demanding applications.

Premium Quality Products

manufacturing high-quality 3D bends with seamless construction and exceptional durability. Each product is engineered to meet stringent industry standards.

Custom Solutions

We offer tailored 3D bend solutions to meet unique project requirements, ensuring you receive the perfect fit for your pipeline systems.

Timely Deliveries

Our efficient production and logistics team ensure on-time delivery, helping you meet project deadlines without delays.

- Lower Pressure Drop: The longer radius allows the fluid to flow more smoothly, reducing friction losses and pressure drop.

- Reduced Turbulence: The smooth, gradual bend minimizes turbulence, making it ideal for applications involving sensitive or high-velocity fluids.

- Increased Durability: 5D elbows experience less wear and tear compared to short-radius elbows, extending the lifespan of the piping system.

- Better Flow Efficiency: Due to the smoother flow path, 5D elbows are ideal for applications requiring high flow rates.

The size of a 5D elbow is primarily determined by the nominal pipe size (NPS) and the centerline radius (R), which is 5 times the NPS. To select the correct elbow size, determine the NPS of your pipe and multiply it by 5 to get the centerline radius. For example:

- For a 2-inch pipe, the centerline radius will be 10 inches (2 × 5).

- For a 6-inch pipe, the centerline radius will be 30 inches (6 × 5).

- A 3D elbow has a radius 3 times the nominal pipe size, offering a shorter bend and higher pressure drop.

- A 5D elbow has a radius 5 times the nominal pipe size, resulting in a longer, smoother bend and lower pressure drop, ideal for high-flow or sensitive applications.