Branch Outlet Pipe Fittings | ASME B16.9, B16.11, B16.25, MSS SP-97

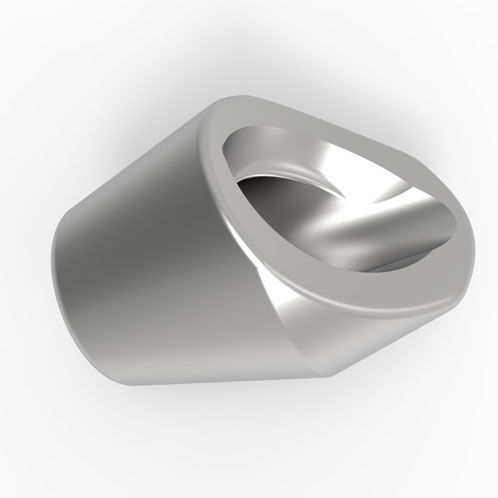

Branch pipe fittings, also known as branch connection fittings or outlet fittings, are specialized components used in piping systems to create a connection between a main pipe and a secondary, branching pipe. These outlet fittings ensure a secure and leak-proof junction, enabling the distribution of fluids or gases to multiple directions. Common types of branch fittings include weldolets, sockolets, threadolets, elbolets, nipolets, and latrolets. Manufactured to strict standards like ASME B16.9, ASME B16.11, and MSS SP-97, branch pipe fittings play a crucial role in the efficient and reliable operation of complex piping systems.

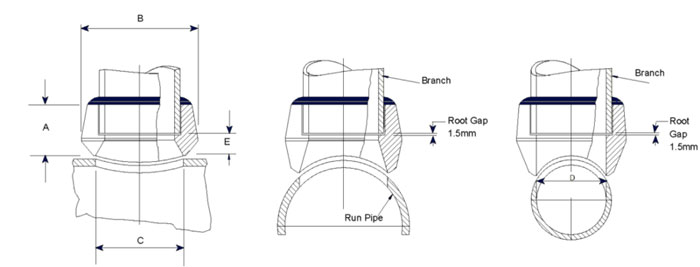

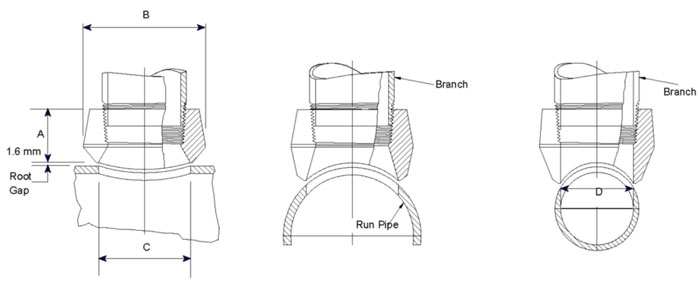

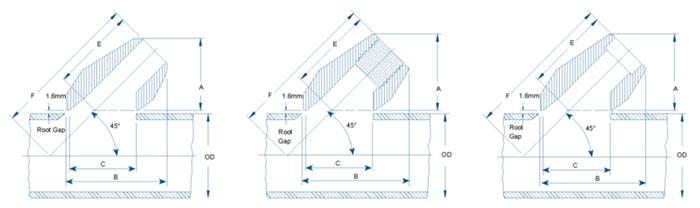

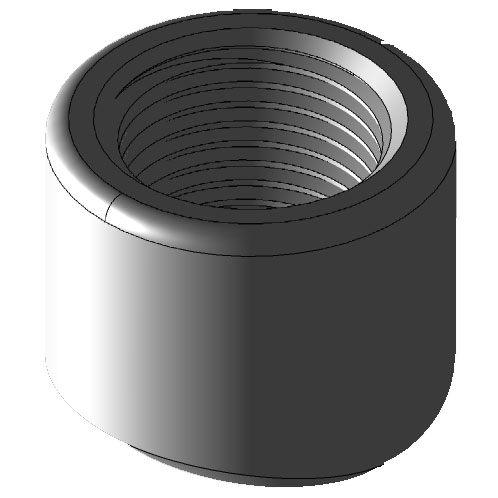

Weldolet is a butt-weld branch fitting used for high-pressure applications, connecting a branch pipe to a main pipe. Sockolet is a socket-weld branch fitting for smaller diameter pipes, commonly used in low-pressure systems. Threadolet is a threaded branch fitting for quick and easy installation in low-pressure piping systems. Elbolet is a branch fitting designed for connection on elbows, enabling branching at angles. Nipolet is a combination of a nipple and olet, used for valve take-offs or small branch connections. Latrolet is a lateral branch fitting, typically installed at a 45-degree angle for directional flow in piping systems.

Ample Alloys is a well-regarded manufacturer and supplier specializing in high-quality piping solutions, offering a wide range of outlet fittings tailored to meet the needs of diverse industries. Known for our precision engineering, We ensure that each product adheres to international standards like ASME, ASTM, DIN, and EN, providing reliability and durability in demanding applications. With a strong commitment to quality, innovation, and timely delivery, we cater to industries such as oil and gas, power generation, petrochemicals, pharmaceuticals, and water treatment. we distinguish ourselves through its customer-centric approach, offering custom solutions and technical expertise to meet specific project requirements.

Weldolet, Sockolet, Threadolet, Elbolet, Nipolet, Flanged Lateral Tee, Butt Weld Branch Connections, Pipe Branching Fittings, Welded Branch Connection, Threaded Branch Fittings, ASME B16.9 Branch Fittings, Branch Connector Fittings, Lateral Branch Fittings, High Pressure Branch Fittings, Custom Branch Fittings

ASME B16.9 Olet Fittings Specifications

Size Range

1/8" to 36" (DN6 to DN900)

Outlets Form

Weldolet, Sockolet, Threadolet, Elbolet, Latrolet, Nipolet, Sweepolet

Stainless Steel

ASTM A182 F304/304L, 304H, 309H, 310H, 316, 316H, 316L, 316Ti, 317/L, 321, 321H, 347, 347H, 904L, 254SMO(S31254)

Standards / Dimension

ASME B16.11, ASME B16.9, MSS SP-97

Carbon Steel

ASTM / ASME A/SA 105.

Alloy Steel

ASTM A182 GR F5, F9, F11, F12, F22, F91 etc.

Pressure Class

3000# (Class 3000), 6000# (Class 6000), 9000# (Class 9000)

Connections

Butt-weld, Socket-weld, Threaded

Duplex & Super Duplex

ASTM A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

| Size | Size in mm | Height A | OD -B | Hole Dia C | Weight in KG |

|---|---|---|---|---|---|

| 1/4 | 8 | 14.3 | 25.4 | 15.9 | 0.04 |

| 3/8 | 10 | 19.05 | 31.75 | 19.05 | 0.07 |

| 1/2 | 15 | 19.05 | 34.93 | 23.81 | 0.08 |

| 3/4 | 20 | 22.23 | 44.45 | 30.16 | 0.11 |

| 1 | 25 | 26.99 | 53.98 | 36.51 | 0.23 |

| 1 1/4 | 32 | 31.75 | 65.09 | 44.45 | 0.36 |

| 1 1/2 | 40 | 33.34 | 73.03 | 50.8 | 0.45 |

| 2 | 50 | 38.1 | 88.9 | 65.09 | 0.79 |

| 2 1/2 | 65 | 41.28 | 103.19 | 76.2 | 1.13 |

| 3 | 80 | 44.45 | 122.24 | 93.66 | 1.81 |

| 3 1/2 | 90 | 47.63 | 142.88 | 112.71 | 2.5 |

| 4 | 100 | 50.8 | 152.4 | 120.65 | 2.86 |

| 5 | 130 | 57.15 | 179.3 | 141.29 | 4.65 |

| 6 | 150 | 60.33 | 215.9 | 169.86 | 6.44 |

| 8 | 200 | 69.85 | 263.53 | 220.66 | 10.66 |

| 10 | 250 | 77.79 | 322.26 | 274.64 | 17.69 |

| 12 | 300 | 85.73 | 377.83 | 325.44 | 26.76 |

| 14 | 350 | 88.9 | 409.58 | 357.19 | 29.94 |

| 16 | 400 | 93.6 | 463.55 | 407.99 | 34.02 |

| 18 | 450 | 96.84 | 520.7 | 458.79 | 44 |

| 20 | 500 | 101.6 | 571.5 | 508 | 53.52 |

| 24 | 600 | 144.5 | 717.5 | 609.6 | 101 |

| 26 | 650 | 155.6 | 778 | 660.4 | 120 |

| 30 | 750 | 174.6 | 893.6 | 762 | 190 |

| 36 | 900 | 206.4 | 1070 | 914.4 | 310 |

| 40 | 1000 | 225.4 | 1187.6 | 1016 | 435 |

| 42 | 1050 | 235 | 1244.6 | 1066.8 | 540 |

| 48 | 1200 | 241.3 | 1404 | 1219.2 | 750 |

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

|---|---|---|---|---|---|

| 1/4 | 8 | N/A | 25.4 | 15.88 | 0.05 |

| 3/8 | 10 | N/A | 31.75 | 19.05 | 0.07 |

| 1/2 | 15 | 19.05 | 34.93 | 23.81 | 0.09 |

| 3/4 | 20 | 22.23 | 44.45 | 30.16 | 0.14 |

| 1 | 25 | 26.99 | 53.98 | 36.51 | 0.21 |

| 1 1/4 | 32 | 31.75 | 65.09 | 44.45 | 0.41 |

| 1 1/2 | 40 | 33.34 | 73.03 | 50.8 | 0.5 |

| 2 | 50 | 38.1 | 88.9 | 65.09 | 0.79 |

| 2 1/2 | 65 | 41.28 | 103.19 | 76.2 | 1.18 |

| 3 | 80 | 44.45 | 122.24 | 93.66 | 1.86 |

| 3 1/2 | 90 | 47.63 | 136.53 | 112.71 | 2.54 |

| 4 | 100 | 50.8 | 152.4 | 120.65 | 2.9 |

| 6 | 150 | 77.79 | 225.43 | 169.86 | 10.43 |

| 8 | 200 | 98.43 | 292.1 | 220.66 | 16.78 |

| 10 | 250 | 93.66 | 323.85 | 265.11 | 20.87 |

| 12 | 300 | 103.1 | 379.41 | 317.5 | 27.67 |

| 14 | 350 | 100.01 | 431.8 | 350.84 | 31.75 |

| 16 | 400 | 106.36 | 466.73 | 403.23 | 46.27 |

| 18 | 450 | 111.13 | 523.88 | 455.61 | 58.97 |

| 20 | 500 | 119.06 | 582.61 | 509.59 | 71.67 |

| 24 | 600 | 152.4 | 722.2 | 609.6 | 142 |

| 26 | 650 | 165.1 | 782.6 | 660.4 | 168 |

| 30 | 750 | 181 | 896.8 | 762 | 218 |

| 36 | 900 | 212.7 | 1074.4 | 914.4 | 404 |

| 40 | 1000 | 235 | 1194 | 1016 | 582 |

| 42 | 1050 | 244.5 | 1250.8 | 1066.8 | 590 |

| 48 | 1200 | 273 | 1425.6 | 1219.2 | 910 |

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

|---|---|---|---|---|---|

| 1/2 | 15 | 28.58 | 34.93 | 14.29 | 0.11 |

| 3/4 | 20 | 31.75 | 44.45 | 19.05 | 0.32 |

| 1 | 25 | 38.1 | 50.8 | 25.4 | 0.38 |

| 1 1/4 | 32 | 44.45 | 61.91 | 33.34 | 0.57 |

| 1 1/2 | 40 | 50.8 | 69.85 | 38.1 | 0.79 |

| 2 | 50 | 55.56 | 80.96 | 42.86 | 0.97 |

| 2 1/2 | 65 | 61.91 | 96.84 | 53.98 | 1.53 |

| 3 | 80 | 73.03 | 120.65 | 73.03 | 2.87 |

| 4 | 100 | 84.14 | 152.4 | 98.43 | 4.76 |

| 5 | 130 | 93.66 | 187.33 | 122.24 | 6.46 |

| 6 | 150 | 104.78 | 220.66 | 146.05 | 12.7 |

| 8 | 200 | 111.12 | 284.16 | 173.04 | 20.41 |

| 10 | 250 | 125.41 | 312.74 | 215.9 | 38.56 |

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

|---|---|---|---|---|---|

| 1/2 | 15 | 28.58 | 34.93 | 14.29 | 0.11 |

| 3/4 | 20 | 31.75 | 44.45 | 19.05 | 0.32 |

| 1 | 25 | 38.1 | 50.8 | 25.4 | 0.38 |

| 1 1/4 | 32 | 44.45 | 61.91 | 33.34 | 0.57 |

| 1 1/2 | 40 | 50.8 | 69.85 | 38.1 | 0.79 |

| 2 | 50 | 55.56 | 80.96 | 42.86 | 0.97 |

| 2 1/2 | 65 | 61.91 | 96.84 | 53.98 | 1.53 |

| 3 | 80 | 73.03 | 120.65 | 73.03 | 2.87 |

| 4 | 100 | 84.14 | 152.4 | 98.43 | 4.76 |

| 5 | 130 | 93.66 | 187.33 | 122.24 | 6.46 |

| 6 | 150 | 104.78 | 220.66 | 146.05 | 12.7 |

| 8 | 200 | 111.12 | 284.16 | 173.04 | 20.41 |

| 10 | 250 | 125.41 | 312.74 | 215.9 | 38.56 |

| Size in Inches | A | B | C | D | E | Weight in KG |

|---|---|---|---|---|---|---|

| 1/8 | 19.05 | 25.40 | 15.88 | 6.83 | 7.14 | 0.05 |

| 1/4 | 19.05 | 25.40 | 15.88 | 9.25 | 7.14 | 0.05 |

| 3/8 | 20.64 | 31.75 | 19.05 | 12.52 | 11.11 | 0.09 |

| 1/2 | 25.40 | 35.72 | 23.02 | 15.80 | 14.29 | 0.14 |

| 3/4 | 26.99 | 43.66 | 29.37 | 20.93 | 14.29 | 0.16 |

| 1 | 33.34 | 50.80 | 36.51 | 26.64 | 19.84 | 0.27 |

| 1 1/4 | 33.34 | 65.09 | 44.45 | 35.05 | 19.05 | 0.39 |

| 1 1/2 | 34.93 | 72.23 | 50.80 | 40.89 | 19.05 | 0.45 |

| 2 | 38.10 | 88.11 | 65.09 | 52.50 | 20.64 | 0.73 |

| 2 1/2 | 39.69 | 103.19 | 76.20 | 62.71 | 19.05 | 1.25 |

| 3 | 44.45 | 122.24 | 93.66 | 77.93 | 23.81 | 1.72 |

| 3 1/2 | 53.98 | 132.56 | 101.60 | 90.12 | 25.40 | 1.95 |

| 4 | 47.63 | 151.61 | 120.65 | 102.26 | 26.99 | 3.29 |

| 5 | 66.68 | 185.74 | 141.29 | 128.19 | 34.13 | 5.44 |

| 6 | 69.85 | 219.08 | 169.86 | 154.05 | 35.72 | 6.58 |

| Size in Inches | A | B | C | D | E | Weight in KG |

|---|---|---|---|---|---|---|

| 1/2 | 31.75 | 43.66 | 19.05 | 11.84 | 22.23 | 0.23 |

| 3/4 | 36.51 | 49.61 | 25.40 | 15.60 | 22.23 | 0.36 |

| 1 | 39.69 | 61.91 | 33.34 | 20.70 | 23.81 | 0.59 |

| 1 1/4 | 41.28 | 69.06 | 38.10 | 29.46 | 20.64 | 0.73 |

| 1 1/2 | 42.86 | 82.55 | 49.21 | 33.99 | 22.23 | 0.91 |

| 2 | 52.39 | 102.39 | 69.85 | 42.90 | 30.16 | 2.34 |

| Size in Inches | A | B | C | D | Weight in KG |

|---|---|---|---|---|---|

| 1/8 | 19.05 | 25.40 | 15.88 | 0.05 | |

| 1/4 | 19.05 | 25.40 | 15.88 | 0.05 | |

| 3/8 | 20.64 | 31.75 | 19.05 | 0.09 | |

| 1/2 | 25.40 | 35.72 | 23.81 | 0.11 | |

| 3/4 | 26.99 | 43.66 | 29.37 | 0.16 | |

| 1 | 33.34 | 50.80 | 36.51 | 0.27 | |

| 1 1/4 | 33.34 | 65.09 | 44.45 | 0.41 | |

| 1 1/2 | 34.93 | 72.23 | 50.80 | 0.45 | |

| 2 | 38.10 | 88.11 | 65.09 | 0.79 | |

| 2 1/2 | 46.04 | 103.19 | 76.20 | 1.36 | |

| 3 | 50.80 | 122.24 | 93.66 | 1.97 | |

| 3 1/2 | 53.98 | 132.56 | 101.60 | 2.61 | |

| 4 | 57.15 | 151.61 | 120.65 | 3.22 | |

| 5 | 66.68 | 185.74 | 141.29 | 5.44 | |

| 6 | 69.85 | 219.08 | 169.86 | 6.94 |

| Size in Inches | A | B | C | D | Weight in KG |

|---|---|---|---|---|---|

| 1/4 | 28.58 | 34.13 | 14.29 | 0.14 | |

| 3/8 | 28.58 | 34.13 | 14.29 | 0.14 | |

| 1/2 | 31.75 | 43.66 | 19.05 | 0.20 | |

| 3/4 | 36.51 | 49.61 | 25.40 | 0.34 | |

| 1 | 39.69 | 61.91 | 33.34 | 0.57 | |

| 1 1/4 | 41.28 | 69.06 | 38.10 | 0.73 | |

| 1 1/2 | 42.86 | 82.55 | 49.21 | 0.88 | |

| 2 | 55.03 | 102.39 | 69.85 | 2.27 |

| Class 3000 Threaded and Socket Weld | ||||

|---|---|---|---|---|

| Size | A | B | C | E |

| 1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

| 1/2 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/4 | 47.63 | 69.85 | 44.45 | 48.42 |

| 1 | 55.56 | 82.55 | 53.98 | 55.56 |

| 1 1/4 | 63.50 | 97.63 | 66.68 | 74.61 |

| 1 1/2 | 69.85 | 107.16 | 76.99 | 66.68 |

| 2 | 85.73 | 138.11 | 104.78 | 80.17 |

| Class 6000 Threaded and Socket Weld | ||||

|---|---|---|---|---|

| Size | A | B | C | E |

| 1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

| 1/2 | 47.63 | 69.85 | 44.45 | 48.42 |

| 3/4 | 55.56 | 82.55 | 53.98 | 55.56 |

| 1 | 63.50 | 92.87 | 66.68 | 62.71 |

| 1 1/4 | 69.85 | 107.16 | 76.99 | 66.68 |

| 1 1/2 | 85.73 | 138.11 | 104.78 | 80.17 |

| 2 | 85.73 | 138.11 | 104.78 | 80.17 |

| Inches | Class 3000 Threaded & Socket Weld Std. & XS Butt-Weld | ||||

|---|---|---|---|---|---|

| Size | A | B | C | D | E |

| 1/4 | Elbow Radius 1.5D (NPS) | Elbow Radius 2D (NPS) | 38.10 | 40.48 | ((Run Pipe O.D.)/2 + Root Gap) / 0.707 + D |

| 3/8 | 38.10 | 40.48 | |||

| 1/2 | 38.10 | 40.48 | |||

| 3/4 | 43.66 | 47.63 | |||

| 1 | 57.15 | 57.15 | |||

| 1 1/4 | 73.03 | 63.50 | |||

| 1 1/2 | 79.38 | 68.26 | |||

| 2 | 106.36 | 82.55 | |||

| 2 1/2 | 106.36 | 82.55 | |||

| 3 | 128.59 | 98.43 | |||

| 4 | 168.28 | 122.24 | |||

| 6 | 238.13 | 165.10 | |||

| 8 | 338.14 | 204.79 | |||

| 10 | 432.59 | 263.53 | |||

| 12 | 498.48 | 282.58 | |||

| Inches | Class 6000 Threaded & Socket Socket-Weld Sch. 160 & XXS Butt-Weld | ||||

|---|---|---|---|---|---|

| Size | A | B | C | D | E |

| 1/4 | Elbow Radius 1.5D (NPS) | Elbow Radius 2D (NPS) | 38.10 | 40.48 | ((Run Pipe O.D.)/2 + Root Gap) / 0.707 + D |

| 3/8 | 38.10 | 40.48 | |||

| 1/2 | 43.66 | 47.63 | |||

| 3/4 | 57.15 | 57.15 | |||

| 1 | 73.03 | 63.50 | |||

| 1 1/4 | 79.38 | 68.26 | |||

| 1 1/2 | 106.36 | 82.55 | |||

Branch Pipe Fittings Standards

Branch pipe fittings are components used to create branch connections in piping systems. They are manufactured according to various standards to ensure compatibility, safety, and reliability in industrial applications.

-

ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

- Covers branch fittings like weldolets, sockolets, and buttweld tees.

- Specifies dimensions, tolerances, material grades, and marking requirements.

-

ASME B16.11 – Forged Steel Fittings, Socket-Welding and Threaded

- Includes branch connection fittings like sockolets, threadolets, and nipolets.

- Applicable for smaller diameter high-pressure systems.

-

MSS SP-97 – Wrought Carbon Steel and Alloy Steel Branch Connection Fittings

- Specifically addresses olet fittings such as weldolets, threadolets, sockolets, and latrolets.

-

ASME B31.3 – Process Piping Code

- Provides guidelines for branch connections in process piping systems, including design and testing.

-

ASTM Standards

- ASTM A105: Specification for carbon steel forgings used for high-pressure fittings like branch connections.

- ASTM A182: Specification for stainless and alloy steel branch fittings.

-

DIN Standards (EN 10253)

- Covers European standards for branch fittings, including buttweld tees and lateral tees.

-

ISO Standards (ISO 3419)

- International standard for pipe fittings, including branch connections.

-

API 602 – Compact Steel Gate Valves and Fittings

- Includes branch fittings for oil and gas applications in smaller bore piping.

-

Common Testing Standards – Compact Steel Gate Valves and Fittings

- EN 10204: Certification of material tests (3.1 / 3.2).

- ASME Section IX: Welding qualification for branch fittings.

- ASTM E112: Grain size for material testing.

- ASME BPVC Section VIII: Pressure testing for branch connection components.

Why Ample Alloys For Outlet Fittings!

By choosing Ample Alloys, customers gain access to top-tier outlet fittings backed by quality, reliability, and exceptional service, ensuring their projects meet the highest standards.

Diverse Range

Weldolets, Sockolets, Threadolets, Elbolets, Latrolets, Nipolets, and Sweepolets for all piping needs.

Customization

Tailored sizes, materials, and finishes for unique applications.

Advanced Processes

Precision-engineered fittings using state-of-the-art technology.

Customer Focus

Technical support, fast response, and tailored solutions.

They are widely used in industries such as oil and gas, petrochemical, power generation, water treatment, shipbuilding, and chemical processing.

Fittings undergo tests like hydrostatic testing, positive material identification (PMI), ultrasonic testing (UT), radiographic testing (RT), and dimensional inspection.

| Header Size | Connection Type |

|---|---|

| 1/2″ thru 6″ NPS | Socket-weld or Threaded |

| 8″ thru 36″ NPS | Socket-weld, Threaded or Butt-weld |

| 42″ & larger NPS | Butt-weld Only |

Available Types of Branch Connection Fittings

Weldolet

Sockolet

Threadolet

Elbolet

Nippolet