Exporter of Socket weld Full, Half Coupling, Reducing Coupling| ASME B16.11, MSS SP-79, 95, 83, 95, 97, BS 3799

Socket Weld Full Coupling are ideal for high-pressure systems, where the pipe is inserted into the fitting socket and welded for a permanent and leak-proof connection. These couplings provide strength and durability.

Threaded Full Coupling on the other hand, offer an easy-to-install solution, where the pipes are screwed into the fitting, making them perfect for low-pressure applications or systems where frequent disassembly is required.

Socket Weld Half Coupling are used when a branch needs to be connected to the main pipe. In this design, only one side of the coupling is welded to the pipe, providing a secure connection with a reduced cost and weight.

Threaded Half Coupling are similar but rely on threading, offering flexibility and ease of installation in non-permanent systems, ideal for applications such as HVAC systems, water distribution, and plumbing.

Socket Weld and Threaded Reducing Couplings are specialized fittings used to connect pipes of different sizes, allowing for smooth transitions and efficient flow in piping systems. These couplings are designed to reduce the pipe size from a larger to a smaller diameter while maintaining the integrity of the system’s pressure and flow capacity.

Ample Alloys is a leading supplier and manufacturer specializing in high-quality forged fittings. With a focus on ASME B16.11 standards. offers a wide range of products, including socket weld, threaded full, half & reducing couplings in various materials. Known for its commitment to superior craftsmanship, timely delivery, and customer satisfaction, Ample Alloys serves industries such as oil & gas, chemical processing, power generation, and more, providing reliable, durable, and high-performance solutions for complex piping systems.

Threaded full, half coupling fittings, Forged pipe couplings, Full coupling forged carbon steel, Half coupling for pipe fittings, Reducing couplings socket weld

Forged Coupling Specifications

Size Range

1/8″~4″ (DN6~DN100) (Socketweld & Screwed-Threaded)

Form

Full Coupling, Half Coupling, Reducing Coupling

Stainless Steel

ASTM A182 & ASME SA182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Carbon Steel

ASTM A105, ASME SA105, A105N, ASTM A350 LF2, ASME SA350, ASTM A694, ASME SA694

Alloy Steel

ASTM A182 & ASME SA182 - F1, F5, F9, F11, F12, F22, F91

Pressure Class

Threaded -2000lb/ 3000lb/ 6000lbs, Socket-weld -3000/ 6000/ 9000lbs

Type

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSPT, BSPP, EN 10204 3.1 and EN 10204 3.2 - NACE

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, 2507.

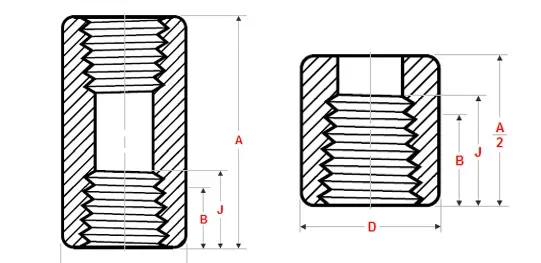

ASME B16.11 Threaded Full and Half Couplings (NPS 1/2 to 4, Class 3000)

| NPS | Length | Outside Dia | Min Thread Length | |

|---|---|---|---|---|

| A | D | B | J | |

| 1/2 | 48 | 28 | 10.9 | 13.6 |

| 3/4 | 51 | 35 | 12.7 | 13.9 |

| 1 | 60 | 44 | 14.7 | 17.3 |

| 1.1/4 | 67 | 57 | 17 | 18 |

| 1.1/2 | 79 | 64 | 17.8 | 18.4 |

| 2 | 86 | 76 | 19 | 19.2 |

| 2.1/2 | 92 | 92 | 23.6 | 28.9 |

| 3 | 108 | 108 | 25.9 | 30.5 |

| 4 | 121 | 140 | 27.7 | 33 |

Threaded Full and Half Couplings (NPS 1/2 to 4, Class 6000)

| NPS | Length | Outside Dia | Min Thread Length | |

|---|---|---|---|---|

| A | D | B | J | |

| 1/2 | 48 | 38 | 10.9 | 13.6 |

| 3/4 | 51 | 44 | 12.7 | 13.9 |

| 1 | 60 | 57 | 14.7 | 17.3 |

| 1.1/4 | 67 | 64 | 17 | 18 |

| 1.1/2 | 79 | 76 | 17.8 | 18.4 |

| 2 | 86 | 92 | 19 | 19.2 |

| 2.1/2 | 92 | 108 | 23.6 | 28.9 |

| 3 | 108 | 127 | 25.9 | 30.5 |

| 4 | 121 | 159 | 27.7 | 33 |

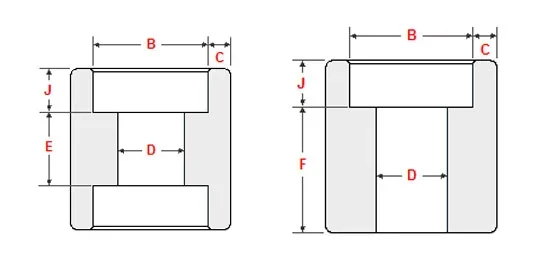

ASME B16.11 Socket Weld Full and Half Couplings (NPS 1/2 to 4, Class 3000)

| NPS | Socket Bore | Depth Socket | Bore DIA | Socket wall THK |

|---|---|---|---|---|

| B | J | D | C | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

| NPS | Laying lengths | |||

| Coupling E |

Half coupling F |

|||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

Socket Weld Full and Half Couplings (NPS 1/2 to 4, Class 6000)

| NPS | Socket Bore | Depth Socket | Bore DIA | Socket wall THK |

|---|---|---|---|---|

| B | J | D | C | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

5.95 5.20 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

6.95 6.05 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

7.90 6.95 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

7.90 6.95 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

8.90 7.80 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

10.90 9.50 |

| NPS | Laying lengths | |||

| Coupling E |

Half coupling F |

|||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

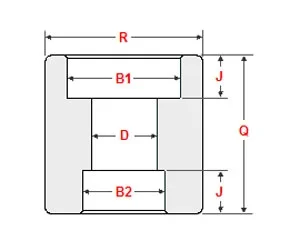

ASME B16.11 Socket Weld Reducing Coupling (Class 3000)

| NPS | Socket Bore | Depth Socket J |

Bore dia | ||

|---|---|---|---|---|---|

| B1 | B2 | B1 | B2 | D | |

| 3/4 1/2 |

27.30 27.05 |

21.95 21.70 |

13 | 10 | 16.6 15 |

| 1 3/4 |

34.05 33.80 |

27.30 27.05 |

13 | 13 | 21.7 20.2 |

| 1 1/2 |

34.05 33.80 |

21.95 21.70 |

13 | 10 | 16.6 15 |

| 1.1/4 1 |

42.80 42.55 |

34.05 33.80 |

13 | 13 | 27.4 25.9 |

| 1.1/2 1 |

48.90 48.65 |

34.05 33.80 |

13 | 13 | 27.4 25.9 |

| 1.1/2 3/4 |

48.90 48.65 |

27.30 27.05 |

13 | 13 | 21.7 20.2 |

| 1.1/2 1/2 |

48.90 48.65 |

21.95 21.70 |

13 | 10 | 16.6 15 |

| 2 1.1/2 |

61.35 61.10 |

48.90 48.65 |

16 | 13 | 41.7 40.1 |

| 2 1 |

74.20 73.80 |

34.05 33.80 |

16 | 13 | 27.4 25.9 |

| NPS | Length Coupling | Diameter Coupling |

|||

|---|---|---|---|---|---|

| Q | R | ||||

| 3/4 1/2 |

35 | 36 | |||

| 1 3/4 |

38.1 | 45.2 | |||

| 1 1/2 |

38.1 | 45.2 | |||

| 1.1/4 1 |

38.1 | 55.1 | |||

| 1.1/2 1 |

38.1 | 60 | |||

| 1.1/2 3/4 |

38.1 | 60 | |||

| 1.1/2 1/2 |

38.1 | 60 | |||

| 2 1.1/2 |

51.3 | 74.9 | |||

| 2 1 |

51.3 | 74.9 | |||

Socket Weld Reducing Coupling (Class 6000)

| NPS | Socket Bore | Depth Socket J |

Bore dia | ||

|---|---|---|---|---|---|

| B1 | B2 | B1 | B2 | D | |

| 3/4 1/2 |

27.30 27.05 |

21.95 21.70 |

13 | 10 | 12.5 11 |

| 1 3/4 |

34.05 33.80 |

27.30 27.05 |

13 | 13 | 16.3 14.8 |

| 1 1/2 |

34.05 33.80 |

21.95 21.70 |

13 | 10 | 12.5 11 |

| 1.1/4 1 |

42.80 42.55 |

34.05 33.80 |

13 | 13 | 21.5 19.9 |

| 1.1/2 1 |

48.90 48.65 |

34.05 33.80 |

13 | 13 | 21.5 19.9 |

| 1.1/2 3/4 |

48.90 48.65 |

27.30 27.05 |

13 | 13 | 16.3 14.8 |

| 1.1/2 1/2 |

48.90 48.65 |

21.95 21.70 |

13 | 10 | 12.5 11 |

| 2 1.1/2 |

61.35 61.10 |

48.90 48.65 |

16 | 13 | 34.7 33.2 |

| 2 1 |

74.20 73.80 |

34.05 33.80 |

16 | 13 | 21.5 19.9 |

| NPS | Length Coupling | Diameter Coupling |

|||

|---|---|---|---|---|---|

| Q | R | ||||

| 3/4 1/2 |

35 | 40.1 | |||

| 1 3/4 |

38.1 | 50 | |||

| 1 1/2 |

38.1 | 50 | |||

| 1.1/4 1 |

38.1 | 57.9 | |||

| 1.1/2 1 |

38.1 | 65 | |||

| 1.1/2 3/4 |

38.1 | 65 | |||

| 1.1/2 1/2 |

38.1 | 65 | |||

| 2 1.1/2 |

51.3 | 82 | |||

| 2 1 |

51.3 | 82 | |||

Forged Coupling Standards

The primary standards for forged couplings are outlined by recognized bodies such as ASME (American Society of Mechanical Engineers) and ANSI (American National Standards Institute), which set the quality and performance requirements for these fittings.

- ASME Standards (American Standards):

- ASME B16.11: Covers forged fittings such as socket weld and threaded fittings for high-pressure applications.

- ASTM A105: Specifies carbon steel forgings for piping components.

- ASTM A182: Standard for forged or rolled alloy and stainless steel materials for high-temperature service.

- ASTM A350: Covers low-alloy and carbon steel forgings for low-temperature applications.

- MSS-SP-79: Socket weld fittings with enhanced dimensions and tolerances.

- MSS-SP-83: Threaded and socket weld unions for the petroleum industry.

- EN (European Standards):

- EN 10222: Forged steel fittings for pressure purposes.

- EN 10241: Steel threaded pipe fittings for the European market.

- EN ISO 17292: Specifications for fittings used in valve systems.

- JIS (Japanese Standards) :

- JIS B2316: Covers forged steel pipe fittings such as elbows, tees, and reducers.

- JIS G3454/G3455: Pressure-resistant pipe materials for fittings.

- International Standards:

- DIN 2605: German standard for forged fittings, particularly elbows.

- BS 3799: British standard for forged pipe fittings in threaded and socket weld types.

- GOST 17375: Russian standard for forged fittings used in high-pressure piping.

- Common Testing Standards:

- ASME B31.3: Testing requirements for process piping.

- NACE MR0175/ISO 15156: Compliance for materials in sour gas environments.

- API 598: Valve and fitting inspection standards.

Why Ample Alloys For Socket Weld Couplings - ASME B16.11 !

Ample Alloys is a trusted supplier for Socket Weld Couplings adhering to ASME B16.11 standards. Our commitment to quality, precision, and reliability sets us apart in the competitive market.

High-Quality Materials

We source only the highest-grade materials, including carbon steel, stainless steel, and alloy steel, ensuring that every coupling we supply meets the stringent requirements for durability and performance.

Strict Compliance with ASME B16.11

Our socket weld couplings meet the ASME B16.11 standards, which ensures they are designed and manufactured to withstand high-pressure environments and provide secure, leak-free connections in critical systems.

Custom Solutions

At Ample Alloys, we offer customized socket weld couplings tailored to meet specific customer requirements, ensuring they fit perfectly into unique piping systems.

Timely Delivery

We understand the importance of meeting deadlines in industrial projects. Our efficient production and logistics teams ensure fast and reliable delivery of couplings, keeping your operations on track.

Socket weld couplings are welded onto the pipe, creating a permanent and strong connection. They are used in high-pressure applications. Threaded couplings, on the other hand, rely on a threaded connection, allowing for easy assembly and disassembly. Threaded couplings are typically used in low-pressure applications.

Yes, both socket weld and threaded couplings can be used in various piping systems, including oil & gas, power generation, and chemical processing. The choice between socket weld and threaded depends on the pressure rating, ease of installation, and maintenance requirements.

A reducing coupling allows you to connect pipes of different diameters, providing a smooth reduction in pipe size without compromising system integrity. It is essential when you need to transition between larger and smaller pipes.