Manufacturer of Threaded Union Fittings| ASME B16.11, MSS SP-79, 83, 95, 97, BS 3799

Socket Weld Unions involve a pipe that is inserted into the socket of the fitting, which is then welded to create a strong, permanent connection. This type of union is ideal for systems that require high-pressure containment and a leak-tight seal. Socket weld unions are commonly used in industries such as oil & gas, chemical processing, and power generation due to their durability and resistance to corrosion.

Threaded Unions are designed to connect pipes via threaded ends, allowing for easy installation and disassembly without the need for welding. This type of union is more suitable for low-pressure systems or situations where the ability to easily remove and replace parts is required. Threaded unions are frequently used in plumbing, water treatment, and other non-high-pressure applications.

Ample Alloys is a trusted supplier and manufacturer of high-quality forged unions that comply with ASME B16.11 standards. With a commitment to excellence, Ample Alloys provides forged unions made from premium materials, ensuring superior durability, strength, and corrosion resistance. Whether you require a socket weld union for high-pressure systems or a threaded union for easy disassembly, We delivers the perfect solution to meet your piping needs. Our products undergo rigorous quality control and testing to guarantee compliance with international standards, providing our customers with reliable, long-lasting fittings that ensure safe and efficient operation in demanding environments. With Ample Alloys, you can trust that you are getting forged unions that not only meet but exceed the industry’s performance standards.

High Quality Socket Weld Unions, ASME B16.11 forged pipe union, Stainless steel forged union, Threaded union for high-pressure systems, Socket weld forged union for water treatment

ASME B16.11 forged union Specifications

Size Range

1/8″~4″ (DN6~DN100)

Form

union

Stainless Steel

ASTM A182 & ASME SA182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Carbon Steel

ASTM A105, ASME SA105, A105N, ASTM A350 LF2, ASME SA350, ASTM A694, ASME SA694

Alloy Steel

ASTM A182 & ASME SA182 - F1, F5, F9, F11, F12, F22, F91

Pressure Class

2000LBS, 3000LBS, 6000LBS, 9000LBS

Type

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, 2507.

ANSI/ASME B16.11 Forged Union

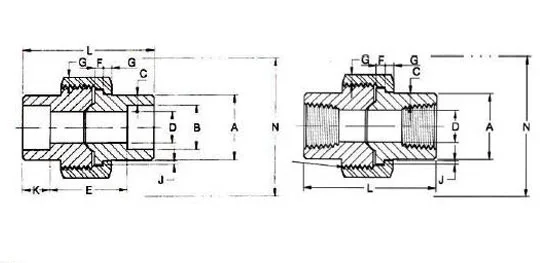

| DIMENSIONS OF THREADED UNION (BS3799) (in mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom Pipe Size (NPS) | Pipe End Min | Socket Bore Dia. | Socket Wall Min. | Water Way Bore | Laying Length | Male Flange Min. | Nut Min. | Threads Per 25.4 Max | Bearing Min. | Depth of Socket Min. | ||

| A | B | C | D | E | F | G | H | J | K | |||

| 1 | 45.5 | 34.04 33.78 |

4.95 | 28.14 27.74 |

34.3 26.2 |

4.57 | 4.44 | 11 | 1.85 | 12.7 | ||

| ½ | 31.2 | 21.84 21.59 |

4.06 | 17.47 17.07 |

26.9 20.6 |

3.68 | 3.68 | 14 | 1.50 | 9.6 | ||

| ¼ | 21.8 | 14.22 13.97 |

3.30 | 9.85 9.45 |

22.4 19.0 |

3.17 | 3.17 | 19 | 1.24 | 9.6 | ||

| 1/8 | 21.8 | 10.92 10.67 |

3.17 | 6.83 6.43 |

22.4 19.0 |

3.17 | 3.17 | 16 | 1.24 | 9.6 | ||

| 3/8 | 25.9 | 17.78 17.53 |

3.48 | 13.92 13.51 |

26.9 20.6 |

3.43 | 3.43 | 14 | 1.37 | 9.6 | ||

| ¾ | 37.1 | 27.18 26.92 |

4.27 | 21.79 21.39 |

31.8 25.4 |

4.06 | 4.06 | 11 | 1.68 | 12.7 | ||

| 11/4 | 54.9 | 42.67 42.42 |

5.28 | 35.76 35.36 |

40.6 32.5 |

5.33 | 5.21 | 11 | 2.13 | 12.7 | ||

| 21/2 | 91.7 | 74.17 73.66 |

7.65 | 64.72 64.31 |

61.7 52.1 |

7.49 | 7.11 | 8 | 3.07 | 15.8 | ||

| 3 | 109.2 | 90.17 89.66 |

8.31 | 77.67 77.27 |

63.8 53.6 |

8.25 | 8.00 | 8 | 3.53 | 15.8 | ||

| 11/2 | 61.5 | 48.77 48.51 |

5.54 | 41.61 41.20 |

42.2 34.0 |

5.84 | 5.59 | 10 | 2.31 | 12.7 | ||

| 2 | 75.2 | 61.47 61.21 |

6.05 | 52.53 52.12 |

45.3 37.3 |

6.60 | 6.35 | 10 | 2.69 | 15.8 | ||

Socket Weld Unions - Forged Fittings Standards

Compliance with ASME B16.11 ensures that the forged unions provide a secure and durable connection, preventing leaks and enhancing the overall integrity of the piping system.

- ASME Standards (American Standards):

- ASME B16.11: Covers forged fittings such as socket weld and threaded fittings for high-pressure applications.

- ASTM A105: Specifies carbon steel forgings for piping components.

- ASTM A182: Standard for forged or rolled alloy and stainless steel materials for high-temperature service.

- ASTM A350: Covers low-alloy and carbon steel forgings for low-temperature applications.

- MSS-SP-79: Socket weld fittings with enhanced dimensions and tolerances.

- MSS-SP-83: Threaded and socket weld unions for the petroleum industry.

- EN (European Standards):

- EN 10222: Forged steel fittings for pressure purposes.

- EN 10241: Steel threaded pipe fittings for the European market.

- EN ISO 17292: Specifications for fittings used in valve systems.

- JIS (Japanese Standards) :

- JIS B2316: Covers forged steel pipe fittings such as elbows, tees, and reducers.

- JIS G3454/G3455: Pressure-resistant pipe materials for fittings.

- International Standards:

- DIN 2605: German standard for forged fittings, particularly elbows.

- BS 3799: British standard for forged pipe fittings in threaded and socket weld types.

- GOST 17375: Russian standard for forged fittings used in high-pressure piping.

- Common Testing Standards:

- ASME B31.3: Testing requirements for process piping.

- NACE MR0175/ISO 15156: Compliance for materials in sour gas environments.

- API 598: Valve and fitting inspection standards.

Why Ample Alloys For Forged Union!

Ample Alloys stands out as a trusted supplier and manufacturer of forged unions that meet and exceed ASME B16.11 standards. With a focus on quality and precision, We ensures that each forged union is crafted from premium materials, providing exceptional durability, strength, and corrosion resistance for demanding applications.

Superior Quality

Our products undergo stringent quality control measures and testing to guarantee that each union meets the highest industry standards for performance and reliability.

Wide Range of Materials

We offer a diverse selection of forged unions made from high-grade materials, ensuring compatibility with various piping systems and applications across industries.

Customization Options

Whether you require socket weld unions for high-pressure systems or threaded unions for ease of installation and removal, , Ample Alloys offers tailored solutions to meet your specific project requirements.

Expertise and Experience

With years of experience in the industry, Ample Alloys is a reliable partner for your piping system needs, providing expert advice and high-quality forged unions that meet your specifications.

- Socket Weld Forged Unions are used for high-pressure applications, where the pipe is inserted into the union socket and welded for a permanent connection.

- Threaded Forged Unions are used in lower pressure systems, where pipes are connected via threaded ends, allowing for easier installation and removal without welding.

- Easy installation and removal for maintenance

- Leak-proof, secure connections

- High pressure and temperature resistance

- Durability and corrosion resistance

- Versatile usage in a variety of industrial systems

Yes, forged unions are available in a wide range of sizes to accommodate various pipe diameters and system requirements. Custom sizes can also be fabricated upon request.