Forged Hex Nipple Pipe Fittings| ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

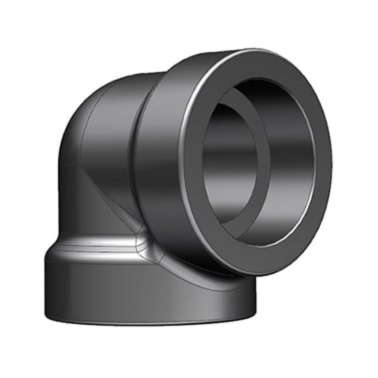

A pipe nipple is a short length of pipe, typically used to connect two other fittings or pipes in a pipeline system. Known for its versatility, it is a key component in industries. They are often threaded on both ends to provide a secure, leak-proof connection. Available in seamless or welded forms, pipe nipples are designed to withstand high pressure and temperature, making them a reliable choice for both industrial and domestic piping needs.

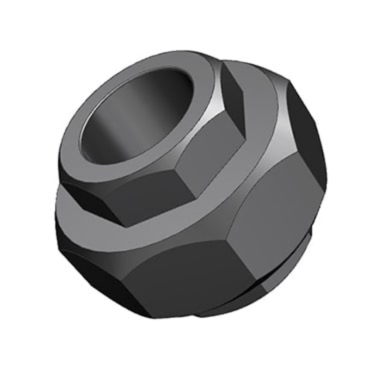

A hex nipple is a specialized fitting featuring external threads on both ends with a hexagonal section in the middle. The hexagonal design allows for easy tightening or loosening using a wrench, making it an essential component for creating secure connections in piping systems. Hex nipples are commonly used to connect pipes or fittings of the same diameter. Their durability and resistance to corrosion ensure long-lasting performance, even in challenging environments.

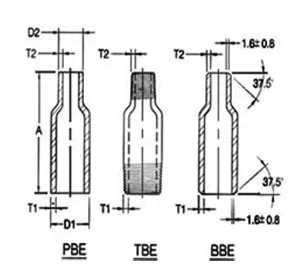

A swage nipple is a reducer fitting that connects pipes or fittings of different diameters. With one end larger than the other, it facilitates smooth transitions between varying pipe sizes, optimizing flow and reducing turbulence. Swage nipples are available in concentric and eccentric types, catering to specific alignment and flow requirements.

Ample Alloys is a renowned manufacturer and supplier of high-quality pipe nipples, offering a wide range of solutions tailored to diverse industrial needs. With years of expertise in the metal industry, We are committed to providing durable, reliable, and precision-engineered products. We specializes in producing pipe nipples in various materials such as stainless steel, carbon steel, alloy steel, nickel alloys, and more, ensuring compatibility with different applications and environments. We are focus on quality, timely delivery, and customer satisfaction makes a trusted partner for pipe nipple solutions. With a global presence, Ample Alloys continues to innovate and cater to evolving market needs, offering products that excel in both performance and durability.

Superior Quality Socket Weld & Threaded Swage Nipple, Stainless Steel Hex Nipple, Carbon Steel Swage Nipple, SS 304/316 Hex Nipple, ANSI Hex Nipple, DIN 2986 Swage Nipple, API Threaded Pipe Nipple, BS3799 Hex Nipple

ASME B16.11 Hex Nipple Specifications

Size Range

1/8″~4″ (DN6~DN100)

Form

Hex Nipple, Swage Nipple

Stainless Steel

ASTM A182 & ASME SA182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Carbon Steel

ASTM A105, ASME SA105, A105N, ASTM A350 LF2, ASME SA350, ASTM A694, ASME SA694

Alloy Steel

ASTM A182 & ASME SA182 - F1, F5, F9, F11, F12, F22, F91

Pressure Class

2000LBS, 3000LBS, 6000LBS, 9000LBS

Type

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, 2507./p>

ASME B16.11 Threaded Swage Nipple Dimensions

| NPS | End To End “A” | Wall Thickness | Outside Diameter | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | Large End D1 | Small End D2 | ||||||||

| Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | ||||

| 1/4”x1/8” | 57 | 2.2 | 3.0 | 3.7 | 6.1 | 1.7 | 2.4 | 13.7 | 10.3 | ||

| 3/8”x1/8” | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 1.7 | 2.4 | 17.1 | 10.3 | ||

| 3/8”x1/4” | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 2.2 | 3.0 | 17.1 | 13.7 | ||

| 1/2”x1/8” | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 1.7 | 2.4 | 21.3 | 10.3 | ||

| 1/2”x1/4” | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.2 | 3.0 | 21.3 | 13.7 | ||

| 1/2”x3/8” | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.3 | 3.2 | 21.3 | 17.1 | ||

| 3/4”x1/8” | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 1.7 | 2.4 | 26.7 | 10.3 | ||

| 3/4’x1/4” | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.2 | 3.0 | 26.7 | 13.7 | ||

| 3/4”x3/8” | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.3 | 3.2 | 26.7 | 17.1 | ||

| 3/4”x1/2” | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.8 | 3.7 | 4.8 | 7.5 | 26.7 | 21.3 |

| 1”x1/8” | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 1.7 | 2.4 | 33.4 | 10.3 | ||

| 1”x1/4” | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.2 | 3.0 | 33.4 | 13.7 | ||

| 1”x3/8” | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.3 | 3.2 | 33.4 | 17.1 | ||

| 1”x1/2” | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.8 | 3.7 | 4.8 | 7.5 | 33.4 | 21.3 |

| 1”x3/4” | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.9 | 3.9 | 5.6 | 7.8 | 33.4 | 26.7 |

| 1-1/4”x1/8” | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 1.7 | 2.4 | 42.2 | 10.3 | ||

| 1-1/4”x1/4” | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.2 | 3.0 | 42.2 | 13.7 | ||

| 1-1/4”x3/8” | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.3 | 3.2 | 42.2 | 17.1 | ||

| 1-1/4”x1/2” | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.8 | 3.7 | 4.8 | 7.5 | 42.2 | 21.3 |

| 1-1/4”x3/4” | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.9 | 3.9 | 5.6 | 7.8 | 42.2 | 26.7 |

| 1-1/4”x1” | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 3.4 | 4.5 | 6.4 | 9.1 | 42.2 | 33.4 |

| 1-1/2”x1/8” | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 1.7 | 2.4 | 48.3 | 10.3 | ||

| 1-1/2”x1/4” | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.2 | 3.0 | 48.3 | 13.7 | ||

| 1-1/2”x3/8” | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.3 | 3.2 | 48.3 | 17.1 | ||

| 1-1/2”x1/2” | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.8 | 3.7 | 4.8 | 7.5 | 48.3 | 21.3 |

| 1-1/2”x3/4” | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.9 | 3.9 | 5.6 | 7.8 | 48.3 | 26.7 |

| 1-1/2”x1” | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.4 | 4.5 | 6.4 | 9.1 | 48.3 | 33.4 |

| 1-1/2”x1-1/4” | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.6 | 4.9 | 6.4 | 9.7 | 48.3 | 42.2 |

| 2”x1/8” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 1.7 | 2.4 | 60.3 | 10.3 | ||

| 2”x1/4” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.2 | 3.0 | 60.3 | 13.7 | ||

| 2”x3/8” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.3 | 3.2 | 60.3 | 17.1 | ||

| 2”x1/2” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.8 | 3.7 | 4.8 | 7.5 | 60.3 | 21.3 |

| 2”x3/4” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.9 | 3.9 | 5.6 | 7.8 | 60.3 | 26.7 |

| 2”x1” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.4 | 4.5 | 6.4 | 9.1 | 60.3 | 33.4 |

| 2”x1-1/4” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.6 | 4.9 | 6.4 | 9.7 | 60.3 | 42.2 |

| 2”x1-1/2” | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.7 | 5.1 | 7.1 | 10.2 | 60.3 | 48.3 |

| 2-1/2”x1/8” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 1.7 | 2.4 | 73.0 | 10.3 | ||

| 2-1/2”x1/4” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.2 | 3.0 | 73.0 | 13.7 | ||

| 2-1/2”x3/8” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.3 | 3.2 | 73.0 | 17.1 | ||

| 2-1/2”x1/2” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.8 | 3.7 | 4.8 | 7.5 | 73.0 | 21.3 |

| 2-1/2”x3/4” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.9 | 3.9 | 5.6 | 7.8 | 73.0 | 26.7 |

| 2-1/2”x1” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.4 | 4.5 | 6.4 | 9.1 | 73.0 | 33.4 |

| 2-1/2”x1-1/4” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.6 | 4.9 | 6.4 | 9.7 | 73.0 | 42.2 |

| 2-1/2”x1-1/2” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.7 | 5.1 | 7.1 | 10.2 | 73.0 | 48.3 |

| 2-1/2”x2” | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.9 | 5.5 | 8.7 | 11.1 | 73.0 | 60.3 |

| 3”x1/8” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 1.7 | 2.4 | 3.2 | 4.8 | 88.9 | 10.3 |

| 3”x1/4” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.2 | 3.0 | 3.7 | 6.1 | 88.9 | 13.7 |

| 3”x3/8” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.3 | 3.2 | 4.0 | 6.4 | 88.9 | 17.1 |

| 3”x1/2” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.8 | 3.7 | 4.8 | 7.5 | 88.9 | 21.3 |

| 3”x3/4” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.9 | 3.9 | 5.6 | 7.8 | 88.9 | 26.7 |

| 3”x1” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.4 | 4.5 | 6.4 | 9.1 | 88.9 | 33.4 |

| 3”x1-1/4” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.6 | 4.9 | 6.4 | 9.7 | 88.9 | 42.2 |

| 3”x1-1/2” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.7 | 5.1 | 7.1 | 10.2 | 88.9 | 48.3 |

| 3”x2” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.9 | 5.5 | 8.7 | 11.1 | 88.9 | 60.3 |

| 3”x2-1/2” | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 5.2 | 7.0 | 9.5 | 14.0 | 88.9 | 73.0 |

| 3-1/2”x1/8” | 203 | 5.7 | 8.1 | 1.7 | 2.4 | 101.6 | 10.3 | ||||

| 3-1/2”x1/4” | 203 | 5.7 | 8.1 | 2.2 | 3.0 | 101.6 | 13.7 | ||||

| 3-1/2”x3/8” | 203 | 5.7 | 8.1 | 2.3 | 3.2 | 101.6 | 17.1 | ||||

| 3-1/2”x1/2” | 203 | 5.7 | 8.1 | 2.8 | 3.7 | 4.8 | 7.5 | 101.6 | 21.3 | ||

| 3-1/2”x3/4” | 203 | 5.7 | 8.1 | 2.9 | 3.9 | 5.6 | 7.8 | 101.6 | 26.7 | ||

| 3-1/2”x1” | 203 | 5.7 | 8.1 | 3.4 | 4.5 | 6.4 | 9.1 | 101.6 | 33.4 | ||

| 3-1/2”x1-1/4” | 203 | 5.7 | 8.1 | 3.6 | 4.9 | 6.4 | 9.7 | 101.6 | 42.2 | ||

| 3-1/2”x1-1/2” | 203 | 5.7 | 8.1 | 3.7 | 5.1 | 7.1 | 10.2 | 101.6 | 48.3 | ||

| 3-1/2”x2” | 203 | 5.7 | 8.1 | 3.9 | 5.5 | 8.7 | 11.1 | 101.6 | 60.3 | ||

| 3-1/2”x2-1/2” | 203 | 5.7 | 8.1 | 5.2 | 7.0 | 9.5 | 14.0 | 101.6 | 73.0 | ||

| 3-1/2”x3” | 203 | 5.7 | 8.1 | 5.5 | 7.6 | 11.1 | 15.2 | 101.6 | 88.9 | ||

| 4”x1/4” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.2 | 3.0 | 114.3 | 13.7 | ||

| 4”x3/8” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.3 | 3.2 | 114.3 | 17.1 | ||

| 4”x1/2” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.8 | 3.7 | 4.8 | 7.5 | 114.3 | 21.3 |

| 4”x3/4” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.9 | 3.9 | 5.6 | 7.8 | 114.3 | 26.7 |

| 4”x1” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.4 | 4.5 | 6.4 | 9.1 | 114.3 | 33.4 |

| 4”x1-1/4” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.6 | 4.9 | 6.4 | 9.7 | 114.3 | 42.2 |

| 4”x1-1/2” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.7 | 5.1 | 7.1 | 10.2 | 114.3 | 48.3 |

| 4”x2” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.9 | 5.5 | 8.7 | 11.1 | 114.3 | 60.3 |

| 4”x2-1/2” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.2 | 7.0 | 9.5 | 14.0 | 114.3 | 73.0 |

| 4”x3” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.5 | 7.6 | 11.1 | 15.2 | 114.3 | 88.9 |

| 4”x3-1/2” | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.7 | 8.1 | 114.3 | 101.6 | ||

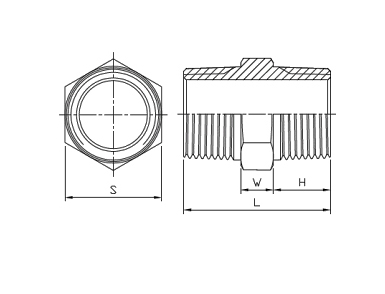

ASME B16.11 Threaded Hex Nipple Dimensions

| Hex Nipple | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | L | S | Size | L | S | ||||

| mm | inch | mm | inch | mm | inch | mm | inch | ||

| 1/8″ | 32 | 1.26 | 13 | 0.52 | 11/4“ | 58 | 2.28 | 46 | 1.81 |

| 1/4″ | 34 | 1.34 | 15 | 0.59 | 11/2“ | 62 | 2.44 | 51 | 2.01 |

| 3/8″ | 36 | 1.42 | 20 | 0.79 | 2″ | 66 | 2.60 | 63 | 2.48 |

| 1/2″ | 42 | 1.65 | 23 | 0.91 | 21/2“ | 73 | 2.87 | 80 | 3.15 |

| 3/4″ | 47 | 1.85 | 29 | 1.14 | 3″ | 86 | 3.39 | 95 | 3.74 |

| 1″ | 52 | 2.05 | 36 | 1.42 | 4″ | 94 | 3.70 | 120 | 4.72 |

Pipe Nipple - Forged Fittings Standards

Pipe nipples are essential components in piping systems and are manufactured to comply with a variety of international standards to ensure quality, reliability, and compatibility. The key standards for forged fittings, including pipe nipples,

- ASME Standards (American Standards):

- ASME B16.11: Covers forged fittings such as socket weld and threaded fittings for high-pressure applications.

- ASTM A105: Specifies carbon steel forgings for piping components.

- ASTM A182: Standard for forged or rolled alloy and stainless steel materials for high-temperature service.

- ASTM A350: Covers low-alloy and carbon steel forgings for low-temperature applications.

- MSS-SP-79: Socket weld fittings with enhanced dimensions and tolerances.

- MSS-SP-83: Threaded and socket weld unions for the petroleum industry.

- EN (European Standards):

- EN 10222: Forged steel fittings for pressure purposes.

- EN 10241: Steel threaded pipe fittings for the European market.

- EN ISO 17292: Specifications for fittings used in valve systems.

- JIS (Japanese Standards) :

- JIS B2316: Covers forged steel pipe fittings such as elbows, tees, and reducers.

- JIS G3454/G3455: Pressure-resistant pipe materials for fittings.

- International Standards:

- DIN 2605: German standard for forged fittings, particularly elbows.

- BS 3799: British standard for forged pipe fittings in threaded and socket weld types.

- GOST 17375: Russian standard for forged fittings used in high-pressure piping.

- Common Testing Standards:

- ASME B31.3: Testing requirements for process piping.

- NACE MR0175/ISO 15156: Compliance for materials in sour gas environments.

- API 598: Valve and fitting inspection standards.

Why Ample Alloys For Forged Nipples!

We stands out as a trusted name for high-quality forged pipe nipples due to its commitment to excellence, precision engineering, and customer satisfaction. Here's why Ample Alloys is the preferred choice:

Customization Options

Ample Alloys provides customized forged nipples to match specific project requirements, including seamless or welded options, threading types, and special coatings for added corrosion resistance.

Expertise and Experience

With years of expertise in manufacturing and supplying forged fittings, Ample Alloys has a deep understanding of industry needs. The team ensures that products are engineered to perform efficiently in demanding environments industries.

Global Reach and Timely Delivery

With a robust supply chain and global distribution network, Ample Alloys ensures timely delivery of products across the globe, making them a reliable partner for urgent project needs.

Customer-Centric Approach

Ample Alloys prioritizes customer satisfaction, offering excellent pre-sales and post-sales support. Their team of experts is always available to provide technical assistance and ensure seamless project execution.

Common types include threaded pipe nipples, plain-end pipe nipples, and seamless or welded pipe nipples.

A hex nipple connects pipes or fittings of the same diameter, while a swage nipple connects pipes of different diameters.

Yes, We are provide pipe nipples in standard and custom sizes to meet specific project requirements.