Piggable Pipe Bend Supplier & Exporter | ASME/ANSI B16.9, ANSI B16.28, MSS SP-75

A piggable pipe bend is a specialized type of pipe bend designed to allow the passage of a "pig" — a device used for cleaning, inspecting, or maintaining pipelines. These bends are typically used in systems where regular cleaning and inspection are necessary, such as in oil and gas pipelines, water treatment plants, and chemical processing facilities. The key feature of a piggable bend is its smooth internal surface and consistent radius, which ensures the pig can pass through the bend without obstruction or damage.

The manufacturing of piggable bends involves precise engineering to ensure the bend radius and the pipe dimensions meet the specifications required for easy passage of pigs. Typically, these bends are fabricated from carbon steel, stainless steel, or other durable alloys, depending on the material requirements of the pipeline. The pipe is carefully bent, and then a smooth, seamless interior is achieved through welding or special machining techniques. Piggable bends may also be designed with full-circumference welds to maintain the integrity and strength of the pipe.

At Ample Alloys, We pride ourselves on our extensive experience in the pipeline industry, offering custom solutions tailored to the specific needs of our clients. Our piggable bends are designed for seamless installation and long-lasting performance, providing essential functionality for oil and gas, chemical, and water treatment systems. Through state-of-the-art manufacturing processes and rigorous quality checks, we ensure that every product we export meets the highest standards of strength, durability, and reliability. Whether for large-scale industrial projects or specialized applications, We are trusted partner for piggable bends, delivering timely and cost-effective solutions globally.

Piggable bend fittings, Piggable elbow bend, Piggable bend pipe, Piggable bend for pipeline, Pipeline piggable bend, Custom piggable bend, Piggable bend for oil and gas, Piggable bend fabrication, High-quality piggable bends

Piggable bends Specifications

Size Range

1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Wall Thickness

Sch 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, XS, 100, 120, 140, 160, Sch XXS

Stainless Steel

ASTM A403 WP 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME B16.9, ASME B16.28, MSS SP-43, MSS SP-75, ASTM A234, ASTM A403, DIN 2605, 2615, 2616, 2617, 10253.

Type / Form

Seamless / ERW / Welded / Fabricated.

Alloy Steel

ASTM A234, WP1, WP5, WP9, WP11, WP22, WP91, etc.

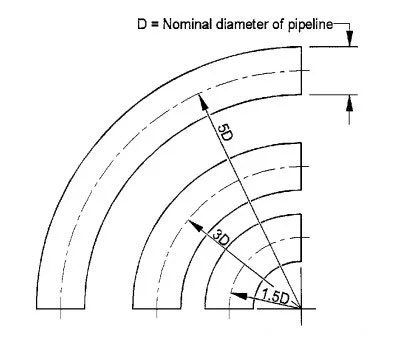

Bending Radius

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Carbon Steel

ASTM A234, A420, MSS-SP-75, WPB, WPL3, WPL6, WPHY 42, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

Duplex & Super Duplex

ASTM A815 / A815M, UNS S31803 / 2205, UNS S32205, UNS S32101 / LDX 2101, UNS S32750 / 2507, UNS S32760, UNS S32550 / Ferralium 255.

Buttweld Piggable bends Dimensions

| Gauge | Stainless Steel Minimum Piggable Bend Radius Includes Minimum Closeness of Cutout to Bend |

Piggable Bend Radius (Refers to Inner Radius) |

|---|---|---|

| 11 gauge (0.120″ |3.05mm) | .5″ | .07″, .08″, .09″, .1″, .125″ |

| 14 gauge (0.075″ | 1.9 mm) | .275″ | .05″, .055″, .062″, .07″, .075″ |

| .375″ | .07″, .105″ | |

| .5″ | .09″, .11″, .115″, .12″ | |

| 1.375″ | .4″ | |

| 16 gauge (0.060″ | 1.52 mm) | .2″ | .035″, .05″ |

| .265″ | .05″, .055″, .075″, .08″ | |

| .375″ | .07″ | |

| .5″ | .105″, .12″ | |

| 18 gauge (0.048″ | 1.22 mm) | .2″ | .04″, .045″, .05″ |

| .265″ | .06″, .07″, .08″, .085″ | |

| .375″ | .1″, .125″ | |

| .5″ | .115″, .12″ | |

| 20 gauge (0.035″ | 0.89 mm) | .2″ | .05″ |

| .265″ | .06″, .07″ | |

| .375″ | .095″ | |

| 22 gauge (0.029″ | 0.74 mm) | .2″ | .05″ |

| .265″ | .04″, .08″ | |

| 24 gauge (0.024″ | 0.61 mm) | .2″ | .04″ |

| .265″ | .08″ |

| Pipe Diameter (inches) | Bend Radius (1.5D) | Bend Radius (2D) | Bend Radius (3D) | Bend Radius (5D) | Wall Thickness (inches) |

|---|---|---|---|---|---|

| 2 | 3.0 | 4.0 | 6.0 | 10.0 | 0.083 - 0.250 |

| 2.5 | 3.75 | 5.0 | 7.5 | 12.5 | 0.083 - 0.250 |

| 3 | 4.5 | 6.0 | 9.0 | 15.0 | 0.083 - 0.250 |

| 4 | 6.0 | 8.0 | 12.0 | 20.0 | 0.083 - 0.375 |

| 5 | 7.5 | 10.0 | 15.0 | 25.0 | 0.109 - 0.375 |

| 6 | 9.0 | 12.0 | 18.0 | 30.0 | 0.109 - 0.500 |

| 8 | 12.0 | 16.0 | 24.0 | 40.0 | 0.109 - 0.625 |

| 10 | 15.0 | 20.0 | 30.0 | 50.0 | 0.125 - 0.750 |

| 12 | 18.0 | 24.0 | 36.0 | 60.0 | 0.125 - 0.875 |

| 14 | 21.0 | 28.0 | 42.0 | 70.0 | 0.188 - 1.000 |

| 16 | 24.0 | 32.0 | 48.0 | 80.0 | 0.188 - 1.125 |

| 18 | 27.0 | 36.0 | 54.0 | 90.0 | 0.250 - 1.250 |

| 20 | 30.0 | 40.0 | 60.0 | 100.0 | 0.250 - 1.375 |

| 24 | 36.0 | 48.0 | 72.0 | 120.0 | 0.312 - 1.500 |

| 30 | 45.0 | 60.0 | 90.0 | 150.0 | 0.375 - 1.750 |

| 36 | 54.0 | 72.0 | 108.0 | 180.0 | 0.375 - 2.000 |

| 42 | 63.0 | 84.0 | 126.0 | 210.0 | 0.500 - 2.250 |

| 48 | 72.0 | 96.0 | 144.0 | 240.0 | 0.500 - 2.500 |

| 54 | 81.0 | 108.0 | 162.0 | 270.0 | 0.625 - 2.750 |

| 60 | 90.0 | 120.0 | 180.0 | 300.0 | 0.625 - 3.000 |

| 72 | 108.0 | 144.0 | 216.0 | 360.0 | 0.750 - 3.500 |

Piggable pipe Bends Tolerance

| Parameter | Tolerance |

|---|---|

| Bend Radius (R) | ± 1% of the specified bend radius |

| Angle of Bend (θ) | ± 1° to ± 3° depending on bend size |

| Centerline Radius | ± 5 mm or ± 1% of the nominal radius |

| Wall Thickness | ± 10% of the specified wall thickness |

| Length of Bend | ± 5 mm or ± 1% of the length |

| Out-of-Square | ≤ 2 mm (maximum) for long radius bends |

| Ovality/Deformation | ≤ 3% of the pipe diameter |

| Radius/Dimension Variation | ± 2% of the nominal dimension |

Piggable elbow bend - Standard Specifications

Standard Specifications of Piggable Pipe Bends outline the key design, material, and manufacturing requirements necessary to ensure the effective function of piggable pipe bends in pipeline systems. These bends are designed to allow the passage of pipeline pigs, ensuring that the internal pipeline is free from obstruction. Below are the key specifications generally followed for piggable pipe bends:

- ASME Standards:

- ASME B16.9: Factory-Made Wrought Buttwelding Fittings.

- ASME B16.25: Buttwelding Ends (preparation of ends for welding).

- ASME Standards: Wrought Steel Buttwelding Short Radius Elbows and Returns.

- ASTM Standards:

- ASTM A234: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service.

- ASTM A403: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings.

- ASTM A815: Standard Specification for Wrought Ferritic, Ferritic/Austenitic (Duplex), and Martensitic Stainless Steel Piping Fittings.

- ASTM A860: Standard Specification for High-Strength Low-Alloy Welded Fittings (commonly used in pipelines with high strength requirements).

- API Standards:

- API 5L: Specification for Line Pipe (not directly for fittings but related to pipe material in oil and gas industries).

- API 6A: Specification for Wellhead and Christmas Tree Equipment (covers piping components but specific to high-pressure environments in oil fields).

- MSS (Manufacturers Standardization Society) Standards:

- MSS SP-43: Wrought and Fabricated Butt-Welding Fittings for Low-Pressure, Corrosion Resistant Applications (commonly used for stainless steel in low-pressure applications).

- MSS SP-75: Specification for High-Strength Wrought, Butt-Welding Fittings (used in oil and gas for high-strength requirements).

- MSS SP-79: Socket-Welding Reducer Inserts.

- MSS SP-83: Carbon Steel Pipe Unions, Socket Welding, and Threaded.

- DIN (Deutsches Institut für Normung) Standards (European):

- DIN 2605: Steel Elbows for Butt Welding (elbows dimensions and tolerances).

- DIN 2615: Tees for Butt Welding.

- DIN 2616: Reducers for Butt Welding.

- DIN 2617: Caps for Butt Welding.

- EN (European Norms) Standards:

- EN 10253-1: Butt-Welding Pipe Fittings Made of Non-Alloy and Alloy Steels.

- EN 10253-2: Butt-Welding Pipe Fittings with Specified Elevated Temperature Properties.

- EN 10253-3: Butt-Welding Pipe Fittings Made of Austenitic and Austenitic-Ferritic (Duplex) Stainless Steel.

- EN 10253-4: Butt-Welding Pipe Fittings for Low-Pressure Applications.

- JIS (Japanese Industrial Standards):

- JIS B2311: Steel Pipe Fittings for Butt-Welding.

- JIS B2312: Cast Iron Pipe Fittings for Butt-Welding.

- JIS B2313: Malleable Iron Pipe Fittings for Butt-Welding.

- ISO (International Standards Organization) Standards:

- ISO 5251: Specifications for Butt-Welding Ends for Steel Pipe Fittings (compatible with ISO pipes and equipment globally).

- ISO 15590: Petroleum and Natural Gas Industries — Induction Bends, Fittings, and Flanges for Pipeline Transportation Systems.

- BS (British Standards):

- BS 1640: Steel Butt-Welding Pipe Fittings for the Petroleum Industry.

- BS 3799: Forged Fittings, Screwed, and Socket-Welding for the Petroleum Industry

Why Ample Alloys for High-quality piggable bends!

By choosing Ample Alloys, you benefit from high-quality, reliable, and precisely manufactured piggable pipe bends that ensure the efficiency, safety, and longevity of your pipeline systems.

Quality Control System

Ensuring excellence through a rigorous Quality Control System that meets the highest industry standards.

Highly Professional Staff

Backed by a team of highly professional staff, we deliver exceptional service and expertise to meet your industry needs.

100% Satisfaction Guarantee

Experience peace of mind with our 100% Satisfaction Guarantee, ensuring top-quality products and services that exceed your expectations.

Accurate Testing Processes

Utilizing precise and accurate testing processes to ensure the highest quality and compliance with industry standards.

The key difference is that piggable bends are designed with a smooth internal surface and a specific radius that allows pigs to pass through without obstruction, while regular bends may not meet these design criteria and could cause blockages or damage to the pigs.

Piggable bends allow for seamless maintenance and inspection of pipelines, ensuring that cleaning pigs and other maintenance tools can pass through without difficulty. This helps in maintaining the integrity of the pipeline and reduces the risk of blockages or corrosion buildup.

The bend radius for piggable bends is usually 1.5 times the diameter of the pipe (1.5D) or more, depending on the specifications and the type of pig to be used. This ensures the pig can move through the bend without hindrance.