Exporter of Buttweld 3D Bend Fittings | ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43

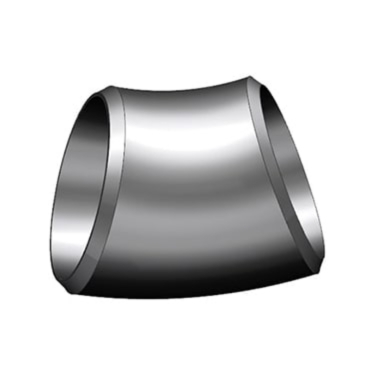

A Buttweld 3D Elbow is a critical component in piping systems, designed to redirect the flow of fluids or gases at an angle while maintaining efficiency and minimizing disruptions. Characterized by a centerline radius that is three times the nominal diameter of the connected pipe, this type of elbow ensures smoother transitions with minimal pressure drop and reduced flow turbulence. Its design is particularly advantageous in applications requiring long service life and high flow efficiency, such as in the oil and gas, petrochemical, and power generation sectors.

Constructed from materials like carbon steel, stainless steel, and specialty alloys, 3D bends are engineered to handle various pressures and temperatures. Their seamless or welded construction complies with global standards such as ASME B16.9, ensuring reliability and performance across diverse industrial environments.

Ample Alloys committed to delivering the highest quality Buttweld 3D Bends by adhering to stringent manufacturing and quality control policies. We prioritize the use of premium-grade materials such as carbon steel, stainless steel, and alloys to ensure durability and performance under diverse operating conditions. All products are manufactured in compliance with international standards like ASME B16.9 and MSS SP-75, ensuring precise dimensions, superior strength, and reliable performance.

Stainless Steel, Carbon Steel, and Alloy Steel 3D Elbow Pipe Fittings, SCH 10 3D Bend, Premium Quality 3D Elbows for Piping Systems, A403 3D Buttweld Elbow, ANSI B16.9 3D Bend Fittings.

Butt weld 3D Elbow Specifications

Size Range

1/2” NB TO 36” NB. (Seamless up to 24”), (Welded 8” TO 36”)

Wall Thickness

Sch 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, XS, 100, 120, 140, 160, Sch XXS

Stainless Steel

ASTM A403 WP 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME B16.9, ASME B16.28, MSS SP-43, MSS SP-75, ASTM A234, ASTM A403, DIN 2605, 2615, 2616, 2617, 10253.

Type / Form

Seamless, Welded, Fabricated / 3D Elbow, Bend.

Alloy Steel

ASTM A234, WP1, WP5, WP9, WP11, WP22, WP91, etc.

Bending Radius

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Carbon Steel

ASTM A234, A420, MSS-SP-75, WPB, WPL3, WPL6, WPHY 42, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

Duplex & Super Duplex

ASTM A815 / A815M, UNS S31803 / 2205, UNS S32205, UNS S32101 / LDX 2101, UNS S32750 / 2507, UNS S32760, UNS S32550 / Ferralium 255.

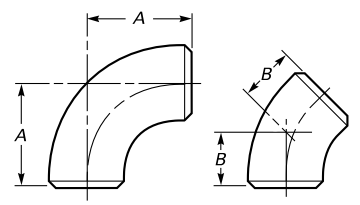

Buttweld 3D Bend Dimensions

| NPS | O.D mm inch |

A mm inch |

B mm inch |

|---|---|---|---|

| 3/4 | 26.7 1.05 |

57 2.25 |

24 0.94 |

| 1 | 33.4 1.32 |

76 3.00 |

31 1.25 |

| 1-1/4 | 42.2 1.66 |

95 3.75 |

39 1.56 |

| 1-1/2 | 48.3 1.90 |

114 4.50 |

47 1.88 |

| 2 | 60.3 2.38 |

152 6.00 |

63 2.50 |

| 2-1/2 | 73.0 2.88 |

190 7.50 |

79 3.12 |

| 3 | 88.9 3.50 |

229 9.00 |

95 3.75 |

| 3-1/2 | 101.6 4.00 |

267 10.50 |

111 4.38 |

| 4 | 114.3 4.50 |

305 12.00 |

127 5.00 |

| 5 | 141.3 5.56 |

381 15.00 |

157 6.19 |

| 6 | 168.3 6.62 |

457 18.00 |

189 7.44 |

| 8 | 219.1 8.62 |

610 24.00 |

252 9.94 |

| 10 | 273.0 10.75 |

762 30.00 |

316 12.44 |

| 12 | 323.8 12.75 |

914 36.00 |

378 14.88 |

| 14 | 355.6 14.00 |

1067 42.00 |

441 17.38 |

| 16 | 406.4 16.00 |

1219 48.00 |

505 19.88 |

| 18 | 457.0 18.00 |

1372 54.00 |

568 22.38 |

| 20 | 508.0 20.00 |

1524 60.00 |

632 24.88 |

| 22 | 559.0 22.00 |

1676 66.00 |

694 27.31 |

| 24 | 610.0 24.00 |

1829 72.00 |

757 29.81 |

| 26 | 660.0 26.00 |

1981 78.00 |

821 32.31 |

| 28 | 711.0 28.00 |

2134 84.00 |

883 34.75 |

| 30 | 762.0 30.00 |

2286 90.00 |

946 37.25 |

| 32 | 813.0 32.00 |

2438 96.00 |

1010 39.75 |

| 34 | 864.0 34.00 |

2591 102.00 |

1073 42.25 |

| 36 | 914.0 36.00 |

2743 108.00 |

1135 44.69 |

BW 3D Bend Dimension Tolerances

| Dimension | Tolerance |

|---|---|

| Radius | ±1% of the nominal radius |

| Angle | ±1° |

| Center-to-End (Length) | ±2% of nominal length |

| Wall Thickness | ±12.5% (according to pipe schedule) |

| Out-of-Roundness | ±2% |

Common Buttweld 3D Elbow Standards

The Buttweld 3D Elbow is commonly manufactured according to several international standards that specify dimensions, tolerances, material specifications, and manufacturing processes. A comprehensive list of 3D Bend pipe fittings standards commonly used across industries like Oil & Gas, Petrochemical, Chemical, Power, and Water Treatment. These standards specify requirements for dimensions, materials, testing, and quality assurance.

- ASME Standards:

- ASME B16.9: Factory-Made Wrought Buttwelding Fittings.

- ASME B16.25: Buttwelding Ends (preparation of ends for welding).

- ASME Standards: Wrought Steel Buttwelding Short Radius Elbows and Returns.

- ASTM Standards:

- ASTM A234: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service.

- ASTM A403: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings.

- ASTM A815: Standard Specification for Wrought Ferritic, Ferritic/Austenitic (Duplex), and Martensitic Stainless Steel Piping Fittings.

- ASTM A860: Standard Specification for High-Strength Low-Alloy Welded Fittings (commonly used in pipelines with high strength requirements).

- API Standards:

- API 5L: Specification for Line Pipe (not directly for fittings but related to pipe material in oil and gas industries).

- API 6A: Specification for Wellhead and Christmas Tree Equipment (covers piping components but specific to high-pressure environments in oil fields).

- MSS (Manufacturers Standardization Society) Standards:

- MSS SP-43: Wrought and Fabricated Butt-Welding Fittings for Low-Pressure, Corrosion Resistant Applications (commonly used for stainless steel in low-pressure applications).

- MSS SP-75: Specification for High-Strength Wrought, Butt-Welding Fittings (used in oil and gas for high-strength requirements).

- MSS SP-79: Socket-Welding Reducer Inserts.

- MSS SP-83: Carbon Steel Pipe Unions, Socket Welding, and Threaded.

- DIN (Deutsches Institut für Normung) Standards (European):

- DIN 2605: Steel Elbows for Butt Welding (elbows dimensions and tolerances).

- DIN 2615: Tees for Butt Welding.

- DIN 2616: Reducers for Butt Welding.

- DIN 2617: Caps for Butt Welding.

- EN (European Norms) Standards:

- EN 10253-1: Butt-Welding Pipe Fittings Made of Non-Alloy and Alloy Steels.

- EN 10253-2: Butt-Welding Pipe Fittings with Specified Elevated Temperature Properties.

- EN 10253-3: Butt-Welding Pipe Fittings Made of Austenitic and Austenitic-Ferritic (Duplex) Stainless Steel.

- EN 10253-4: Butt-Welding Pipe Fittings for Low-Pressure Applications.

- JIS (Japanese Industrial Standards):

- JIS B2311: Steel Pipe Fittings for Butt-Welding.

- JIS B2312: Cast Iron Pipe Fittings for Butt-Welding.

- JIS B2313: Malleable Iron Pipe Fittings for Butt-Welding.

- ISO (International Standards Organization) Standards:

- ISO 5251: Specifications for Butt-Welding Ends for Steel Pipe Fittings (compatible with ISO pipes and equipment globally).

- ISO 15590: Petroleum and Natural Gas Industries — Induction Bends, Fittings, and Flanges for Pipeline Transportation Systems.

- BS (British Standards):

- BS 1640: Steel Butt-Welding Pipe Fittings for the Petroleum Industry.

- BS 3799: Forged Fittings, Screwed, and Socket-Welding for the Petroleum Industry

Why Ample Alloys for 3D Bends!

Ample Alloys is a reliable choice for 3D bends and other pipe fittings due to several key reasons. Their reputation in the manufacturing industry is built on high-quality products and an unwavering commitment to meeting international standards. Here are some reasons why Ample Alloys is a preferred supplier for 3D bends:

Premium Quality Products

manufacturing high-quality 3D bends with seamless construction and exceptional durability. Each product is engineered to meet stringent industry standards.

Advanced Manufacturing Expertise

With state-of-the-art facilities and cutting-edge technology, we produce 3D bends that ensure precision, reliability, and superior performance in demanding applications.

Custom Solutions

We offer tailored 3D bend solutions to meet unique project requirements, ensuring you receive the perfect fit for your pipeline systems.

Timely Deliveries

Our efficient production and logistics team ensure on-time delivery, helping you meet project deadlines without delays.

- Oil and Gas: For transferring fluids and gases in pipelines.

- Power Generation: In steam and water piping systems.

- Chemical Processing: To handle corrosive fluids.

- Water Treatment: For changing the direction of water flow in treatment plants.

- HVAC Systems: For directing air flow in ductwork.

- A 3D Bend typically refers to a smooth pipe bend with a gentle curve, usually used in long-radius applications.

- A 3D Elbow refers to a pre-fabricated elbow fitting with a defined angle (e.g., 90°, 45°), which also follows a 3D radius.

- Cold Bending: A process that involves using specialized machines to bend the pipe at room temperature.

- Hot Bending: Involves heating the pipe to a specific temperature to make it more malleable before bending.

- Induction Bending: Uses electromagnetic induction to heat the pipe locally, making it easier to form the bend.