Supplier of ASME B16.9 BW 10D Bend Pipe Fittings

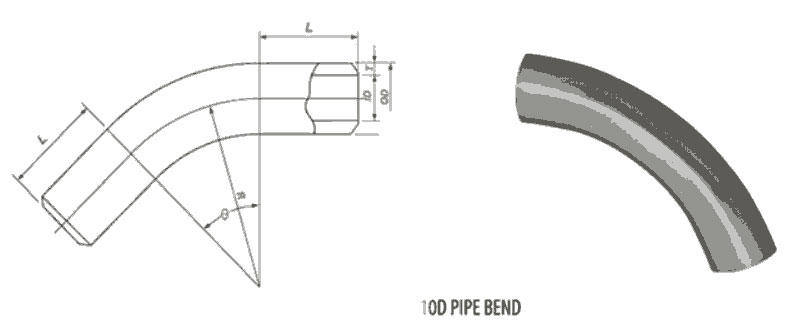

A 10D pipe bend is a highly versatile and essential component in piping systems, particularly in industries such as oil & gas, power generation, and construction. The term 10D refers to the radius of the bend, which is 10 times the nominal diameter (D) of the pipe. For example, for a pipe with a nominal diameter of 6 inches, the radius of the bend would be 60 inches. This type of pipe bend is designed to change the direction of the pipeline and is often used in systems that require a smoother transition between sections of pipe.

Ample Alloys is a renowned manufacturer and stockist of high-quality 10D pipe elbows, offering reliable solutions for various industrial applications. With expertise in providing durable and precision-engineered pipe fittings, We ensures that each 10D elbow is crafted to meet stringent quality standards. Our extensive inventory caters to diverse needs in industries like oil and gas, power generation, and construction, delivering exceptional performance and longevity in every product. Whether custom or standard sizes, We are committed to providing the best in class fittings for optimal system efficiency.

Long radius 10D pipe bend, 10D pipe fittings, 10D bend elbow, Pipe elbow 10D, 10D radius bend, High-quality 10D pipe bend, Custom 10D elbow, 10D long radius elbow, Stainless steel 10D bend, Carbon steel 10D pipe elbow, 10D bend for pipeline, Industrial 10D elbows, 10D pipe elbow fittings

ASME/ANSI B16.9 10D Pipe Bend Specifications

Size Range

1/2″NB TO 48″NB. (Seamless / ERW / Welded / Fabricated)

Wall Thickness

Sch 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, XS, 100, 120, 140, 160, Sch XXS

Stainless Steel

ASTM A403 WP 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME B16.9, ASME B16.28, MSS SP-43, MSS SP-75, ASTM A234, ASTM A403, DIN 2605, 2615, 2616, 2617, 10253.

Type / Form

Seamless, Welded, Fabricated / 10D Elbow, Bend.

Alloy Steel

ASTM A234, WP1, WP5, WP9, WP11, WP22, WP91, etc.

Bending Radius

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Carbon Steel

ASTM A234, A420, MSS-SP-75, WPB, WPL3, WPL6, WPHY 42, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

Duplex & Super Duplex

ASTM A815 / A815M, UNS S31803 / 2205, UNS S32205, UNS S32101 / LDX 2101, UNS S32750 / 2507, UNS S32760, UNS S32550 / Ferralium 255.

Long radius 10D pipe bend Dimensions

| Gauge | Includes Minimum Closeness of Cutout to Bend | (Refers to Inner Radius) |

|---|---|---|

| 11 gauge (0.120" |3.05mm) | .5" | .07", .08", .09", .1", .125" |

| 14 gauge (0.075" | 1.9 mm) | .275" | .05", .055", .062", .07", .075" |

| .375" | .07", .105" | |

| .5" | .09", .11", .115", .12" | |

| 1.375" | .4" | |

| 16 gauge (0.060" | 1.52 mm) | .2" | .035", .05" |

| .265" | .05", .055", .075", .08" | |

| .375" | .07" | |

| .5" | .105", .12" | |

| 18 gauge (0.048" | 1.22 mm) | .2" | .04", .045", .05" |

| .265" | .06", .07", .08", .085" | |

| .375" | .1", .125" | |

| .5" | .115", .12" | |

| 20 gauge (0.035" | 0.89 mm) | .2" | .05" |

| .265" | .06", .07" | |

| .375" | .095" | |

| 22 gauge (0.029" | 0.74 mm) | .2" | .05" |

| .265" | .04", .08" | |

| 24 gauge (0.024" | 0.61 mm) | .2" | .04" |

| .265" | .08" |

10D pipe elbow tolerance

| Tolerance Type | Description | Tolerance Range |

|---|---|---|

| Radius Tolerance | Deviation from the specified bend radius (10 times the pipe diameter) | ±1% to ±5% of the nominal radius |

| Angle Tolerance | Deviation from the specified bend angle (e.g., 90 degrees) | ±1° to ±2° |

| Wall Thickness Tolerance | Deviation from the specified wall thickness (per schedule) | ±10% of the specified wall thickness |

| Out-of-Roundness | Deviation in the circular shape of the elbow | 2% to 5% of the nominal diameter |

| Length Tolerance | Deviation from the specified centerline length | ±1/8 inch (small sizes), ±1/4 inch (large sizes) |

Common Buttweld 10D Elbow Standards

Common Buttweld 10D Elbow Standards are typically governed by various industry and manufacturing codes to ensure consistency, quality, and safety in piping systems. Below are some of the key standards for 10D elbows:

- ASME Standards:

- ASME B16.9: Factory-Made Wrought Buttwelding Fittings.

- ASME B16.25: Buttwelding Ends (preparation of ends for welding).

- ASME Standards: Wrought Steel Buttwelding Short Radius Elbows and Returns.

- ASTM Standards:

- ASTM A234: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service.

- ASTM A403: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings.

- ASTM A815: Standard Specification for Wrought Ferritic, Ferritic/Austenitic (Duplex), and Martensitic Stainless Steel Piping Fittings.

- ASTM A860: Standard Specification for High-Strength Low-Alloy Welded Fittings (commonly used in pipelines with high strength requirements).

- API Standards:

- API 5L: Specification for Line Pipe (not directly for fittings but related to pipe material in oil and gas industries).

- API 6A: Specification for Wellhead and Christmas Tree Equipment (covers piping components but specific to high-pressure environments in oil fields).

- MSS (Manufacturers Standardization Society) Standards:

- MSS SP-43: Wrought and Fabricated Butt-Welding Fittings for Low-Pressure, Corrosion Resistant Applications (commonly used for stainless steel in low-pressure applications).

- MSS SP-75: Specification for High-Strength Wrought, Butt-Welding Fittings (used in oil and gas for high-strength requirements).

- MSS SP-79: Socket-Welding Reducer Inserts.

- MSS SP-83: Carbon Steel Pipe Unions, Socket Welding, and Threaded.

- DIN (Deutsches Institut für Normung) Standards (European):

- DIN 2605: Steel Elbows for Butt Welding (elbows dimensions and tolerances).

- DIN 2615: Tees for Butt Welding.

- DIN 2616: Reducers for Butt Welding.

- DIN 2617: Caps for Butt Welding.

- EN (European Norms) Standards:

- EN 10253-1: Butt-Welding Pipe Fittings Made of Non-Alloy and Alloy Steels.

- EN 10253-2: Butt-Welding Pipe Fittings with Specified Elevated Temperature Properties.

- EN 10253-3: Butt-Welding Pipe Fittings Made of Austenitic and Austenitic-Ferritic (Duplex) Stainless Steel.

- EN 10253-4: Butt-Welding Pipe Fittings for Low-Pressure Applications.

- JIS (Japanese Industrial Standards):

- JIS B2311: Steel Pipe Fittings for Butt-Welding.

- JIS B2312: Cast Iron Pipe Fittings for Butt-Welding.

- JIS B2313: Malleable Iron Pipe Fittings for Butt-Welding.

- ISO (International Standards Organization) Standards:

- ISO 5251: Specifications for Butt-Welding Ends for Steel Pipe Fittings (compatible with ISO pipes and equipment globally).

- ISO 15590: Petroleum and Natural Gas Industries — Induction Bends, Fittings, and Flanges for Pipeline Transportation Systems.

- BS (British Standards):

- BS 1640: Steel Butt-Welding Pipe Fittings for the Petroleum Industry.

- BS 3799: Forged Fittings, Screwed, and Socket-Welding for the Petroleum Industry

Why Ample Alloys for 10D Pipe Bends!

Ample Alloys stands out as a trusted manufacturer and supplier of 10D pipe bends, offering exceptional quality and reliability for a wide range of industrial applications. Here's why Ample Alloys is the ideal choice for your 10D pipe bend needs:

Custom Solutions

We offer tailored 3D bend solutions to meet unique project requirements, ensuring you receive the perfect fit for your pipeline systems.

Advanced Manufacturing Expertise

With state-of-the-art facilities and cutting-edge technology, we produce 3D bends that ensure precision, reliability, and superior performance in demanding applications.

Premium Quality Products

manufacturing high-quality 3D bends with seamless construction and exceptional durability. Each product is engineered to meet stringent industry standards.

Timely Deliveries

Our efficient production and logistics team ensure on-time delivery, helping you meet project deadlines without delays.

The "10D" radius ensures a gradual change in direction, which helps maintain the flow rate and minimizes the pressure drop within the pipe system. The larger the radius, the smoother the bend, making 10D pipe bends ideal for systems requiring minimal turbulence or stress.

10D pipe bends are used across various industries, including oil and gas, petrochemical, power generation, construction, water treatment, and chemical processing. They are ideal for applications where smooth flow and minimal disruption to the pipeline are essential.

Testing for 10D pipe bends includes methods like pressure testing, visual inspection, and dimensional verification to ensure they meet the required standards for quality, strength, and performance. Additional tests such as X-ray inspection or ultrasonic testing may be performed for critical applications.