Manufacturer of Forged Street Elbow Fittings | ASME 16.11, BS 3799

A Threaded Street Elbow is a versatile pipe fitting designed to change the direction of flow in a piping system. Unlike standard elbows, a street elbow has a female thread on one end and a male thread on the other, allowing it to connect directly to other fittings or pipes without the need for additional couplings. This unique design makes it ideal for tight spaces or configurations where a compact connection is required. Threaded street elbows are commonly available in 90° and 45° angles and are widely used in plumbing, HVAC systems, and low-pressure industrial applications. typically made from materials such as stainless steel, carbon steel, brass, or galvanized iron, ensuring durability and resistance to corrosion. Their ease of installation and cost-effectiveness make them a popular choice for applications that require frequent assembly and disassembly.

Ample Alloys operates with a focus on delivering high-quality metal products through a combination of advanced manufacturing techniques and stringent quality control processes. Our specializes in producing a wide range of fittings, including threaded street elbows, by utilizing state-of-the-art machinery and skilled craftsmanship to ensure precision and durability. Each product undergoes rigorous testing to meet international standards, guaranteeing reliable performance across various industries. With a customer-centric approach, We provides customized solutions, competitive pricing, and timely delivery to meet the unique needs of clients worldwide.

Industrial piping street elbow fittings, Precision-engineered street elbow, 90°, 45° threaded street elbow, Male and female threaded elbow, Plumbing street elbow, Stainless steel threaded street elbow, Carbon steel street elbow, Brass threaded street elbow, Galvanized street elbow, Threaded elbow for HVAC systems

Threaded Street Elbow Specifications

Size Range

1/8″~4″ (DN6~DN100)

Form

90°, 45° Elbow, Long Radius Elbow, Short Radius Elbow, LR Elbow, SR Elbow.

Stainless Steel

ASTM A182 & ASME SA182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Carbon Steel

ASTM A105, ASME SA105, A105N, ASTM A350 LF2, ASME SA350, ASTM A694, ASME SA694

Alloy Steel

ASTM A182 & ASME SA182 - F1, F5, F9, F11, F12, F22, F91

Pressure Class

2000LBS, 3000LBS, 6000LBS, 9000LBS

Type

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, 2507.

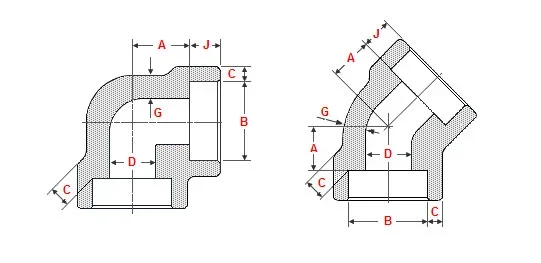

ASME B16.11 Socket Weld 90° & 45° Elbow Dimensions (NPS 1/2 to 2, Class 3000)

| NPS | Socket Bore | Depth Socket | Bore DIA | Socket WT | Body WT |

|---|---|---|---|---|---|

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

3.75 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

3.90 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

4.55 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

4.85 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

5.10 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

5.55 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

7.00 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

7.60 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

8.55 |

| NPS | Center to bottom of socket A |

||||

| 90° | 45° | ||||

| 1/2 | 15.5 | 11.5 | |||

| 3/4 | 19.5 | 12.5 | |||

| 1 | 22 | 14 | |||

| 1.1/4 | 27 | 17 | |||

| 1.1/2 | 32 | 21 | |||

| 2 | 38 | 25 | |||

| 2.1/2 | 41.5 | 29 | |||

| 3 | 57.5 | 31.5 | |||

| 4 | 66.5 | 41.5 | |||

Socket Weld (90° & 45°) Elbow Dimensions (NPS 1/2 to 2, Class 6000)

| NPS | Socket Bore | Depth Socket | Bore DIA | Socket WT | Body WT |

|---|---|---|---|---|---|

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

5.95 5.20 |

4.80 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

6.95 6.05 |

5.55 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

7.90 6.95 |

6.35 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

7.90 6.95 |

6.35 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

8.90 7.80 |

7.15 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

10.90 9.50 |

8.75 |

| NPS | Center to bottom of socket A |

||||

| 90° | 45° | ||||

| 1/2 | 19.5 | 12.5 | |||

| 3/4 | 22.5 | 14.5 | |||

| 1 | 27 | 17 | |||

| 1.1/4 | 32 | 21 | |||

| 1.1/2 | 38 | 25 | |||

| 2 | 41 | 29 | |||

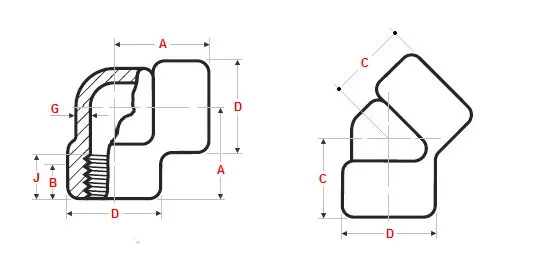

ASME B16.11 Threaded Elbows (90°/45°) - (NPS 1/2 to 4, Class 2000)

| NPS | Min Thread Length | Outside Dia | Min WT | Center to End | ||

|---|---|---|---|---|---|---|

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 33 | 3.18 | 28 | 22 |

| 3/4 | 12.7 | 13.9 | 38 | 3.18 | 33 | 25 |

| 1 | 14.7 | 17.3 | 46 | 3.68 | 38 | 28 |

| 1.1/4 | 17 | 18 | 56 | 3.89 | 44 | 33 |

| 1.1/2 | 17.8 | 18.4 | 62 | 4.01 | 51 | 35 |

| 2 | 19 | 19.2 | 75 | 4.27 | 60 | 43 |

| 2.1/2 | 23.6 | 28.9 | 92 | 5.61 | 76 | 52 |

| 3 | 25.9 | 30.5 | 109 | 5.99 | 86 | 64 |

| 4 | 27.7 | 33 | 146 | 6.55 | 106 | 79 |

Threaded Elbows (90°/45°) - (NPS 1/2 to 4, Class 3000)

| NPS | Min Thread Length | Outside Dia | Min WT | Center to End | ||

|---|---|---|---|---|---|---|

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 38 | 4.09 | 33 | 25 |

| 3/4 | 12.7 | 13.9 | 46 | 4.32 | 38 | 28 |

| 1 | 14.7 | 17.3 | 56 | 4.98 | 44 | 33 |

| 1.1/4 | 17 | 18 | 62 | 5.28 | 51 | 35 |

| 1.1/2 | 17.8 | 18.4 | 75 | 5.56 | 60 | 43 |

| 2 | 19 | 19.2 | 84 | 7.14 | 64 | 44 |

| 2.1/2 | 23.6 | 28.9 | 102 | 7.65 | 83 | 52 |

| 3 | 25.9 | 30.5 | 121 | 8.84 | 95 | 64 |

| 4 | 27.7 | 33 | 152 | 11.18 | 114 | 79 |

Threaded Elbows (90°/45°) - (NPS 1/2 to 4, Class 6000)

| NPS | Min Thread Length | Outside Dia | Min WT | Center to End | ||

|---|---|---|---|---|---|---|

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 46 | 8.15 | 38 | 28 |

| 3/4 | 12.7 | 13.9 | 56 | 8.53 | 44 | 33 |

| 1 | 14.7 | 17.3 | 62 | 9.93 | 51 | 35 |

| 1.1/4 | 17 | 18 | 75 | 10.59 | 60 | 43 |

| 1.1/2 | 17.8 | 18.4 | 84 | 11.07 | 64 | 44 |

| 2 | 19 | 19.2 | 102 | 12.09 | 83 | 52 |

| 2.1/2 | 23.6 | 28.9 | 121 | 15.29 | 95 | 64 |

| 3 | 25.9 | 30.5 | 146 | 16.64 | 106 | 79 |

| 4 | 27.7 | 33 | 152 | 18.67 | 114 | 79 |

Threaded Street Elbows - (NPS 1/2 to 4, Class 3000)

| NPS | Center to Female End | Center to Male End | Outside Dia | Min WT | Min WT |

|---|---|---|---|---|---|

| A | C | D | G1 | G2 | |

| 1/2 | 28 | 41 | 38 | 4.09 | 4.16 |

| 3/4 | 35 | 48 | 44 | 4.32 | 4.88 |

| 1 | 44 | 57 | 51 | 4.98 | 5.56 |

| 1.1/4 | 51 | 66 | 62 | 5.28 | 5.56 |

| 1.1/2 | 54 | 71 | 70 | 5.56 | 6.25 |

| 2 | 64 | 84 | 84 | 7.14 | 7.64 |

| NPS | Min Length Internal Thread | Min Length Male Thread | |||

| B | J1 | J2 | |||

| 1/2 | 10.9 | 13.6 | 14 | ||

| 3/4 | 12.7 | 13.9 | 16 | ||

| 1 | 14.7 | 17.3 | 19 | ||

| 1.1/4 | 17 | 18 | 21 | ||

| 1.1/2 | 17.8 | 18.4 | 21 | ||

| 2 | 19 | 19.2 | 22 | ||

Threaded Street Elbows - (NPS 1/2 to 4, Class 6000)

| NPS | Center to Female End | Center to Male End | Outside Dia | Min WT | Min WT |

|---|---|---|---|---|---|

| A | C | D | G1 | G2 | |

| 1/2 | 35 | 48 | 44 | 8.15 | 6.53 |

| 3/4 | 44 | 57 | 51 | 8.53 | 6.86 |

| 1 | 51 | 66 | 62 | 9.93 | 7.95 |

| 1.1/4 | 54 | 71 | 70 | 10.59 | 8.48 |

| 1.1/2 | 64 | 84 | 84 | 11.07 | 8.89 |

| 2 | 83 | 105 | 102 | 12.09 | 9.70 |

| NPS | Min Length Internal Thread | Min Length Male Thread | |||

| B | J1 | J2 | |||

| 1/2 | 10.9 | 13.6 | 14 | ||

| 3/4 | 12.7 | 13.9 | 16 | ||

| 1 | 14.7 | 17.3 | 19 | ||

| 1.1/4 | 17 | 18 | 21 | ||

| 1.1/2 | 17.8 | 18.4 | 21 | ||

| 2 | 19 | 19.2 | 22 | ||

90° / 45° Elbow - Forged Pipe Fittings Standards

Forged Fittings are manufactured and tested according to internationally recognized standards to ensure safety, quality, and compatibility across various industries. Below are the key standards associated with forged pipe fittings:

- ASME Standards (American Standards):

- ASME B16.11: Covers forged fittings such as socket weld and threaded fittings for high-pressure applications.

- ASTM A105: Specifies carbon steel forgings for piping components.

- ASTM A182: Standard for forged or rolled alloy and stainless steel materials for high-temperature service.

- ASTM A350: Covers low-alloy and carbon steel forgings for low-temperature applications.

- MSS-SP-79: Socket weld fittings with enhanced dimensions and tolerances.

- MSS-SP-83: Threaded and socket weld unions for the petroleum industry.

- EN (European Standards):

- EN 10222: Forged steel fittings for pressure purposes.

- EN 10241: Steel threaded pipe fittings for the European market.

- EN ISO 17292: Specifications for fittings used in valve systems.

- JIS (Japanese Standards) :

- JIS B2316: Covers forged steel pipe fittings such as elbows, tees, and reducers.

- JIS G3454/G3455: Pressure-resistant pipe materials for fittings.

- International Standards:

- DIN 2605: German standard for forged fittings, particularly elbows.

- BS 3799: British standard for forged pipe fittings in threaded and socket weld types.

- GOST 17375: Russian standard for forged fittings used in high-pressure piping.

- Common Testing Standards:

- ASME B31.3: Testing requirements for process piping.

- NACE MR0175/ISO 15156: Compliance for materials in sour gas environments.

- API 598: Valve and fitting inspection standards.

Why Ample Alloys For Forged Elbows!

Ample Alloys emphasizes rigorous quality checks, competitive pricing, and on-time delivery, making a preferred choice for clients seeking durable and efficient piping solutions. our dedication to customer satisfaction and ability to provide customized solutions further highlights our leadership in the forged elbows market.

High-Quality Products

Ample Alloys manufactures durable 45° and 90° forged elbows, including socket weld and threaded options, ensuring superior performance in demanding applications.

Material Variety

Offers a wide range of materials, including stainless steel, carbon steel, and alloy steel, suitable for various industries and applications.

Precision Engineering

Each forged elbow is manufactured with precision to meet international standards, ensuring reliable performance under high-pressure and high-temperature conditions.

Customized Solutions

Provides tailored solutions to meet specific project requirements, catering to diverse industry needs.

- Connection: Socket weld elbows require welding, while threaded elbows are screwed on.

- Application: Socket weld elbows are preferred for high-pressure and high-temperature environments; threaded elbows are used for ease of assembly in lower-pressure systems.

These elbows are manufactured to meet standards like ASME B16.11, ensuring quality, durability, and compatibility with piping systems.

Forged elbows provide superior strength, durability, and resistance to high pressures and temperatures, ensuring reliable performance in critical applications.