DIN PN40 Flange, DIN PN16 Flange, DIN 2573-PN6 Flange, DIN 2576-PN10 Flange

DIN Flanges are standardized pipe flanges developed by the German Institute for Standardization (Deutsches Institut für Normung, or DIN). These flanges are widely used in piping systems across Europe and other regions for connecting pipes, valves, and other equipment. DIN flanges come in various pressure ratings, such as PN6, PN10, PN16, PN25, PN40, and PN100, making them suitable for a wide range of applications, from low-pressure systems to high-pressure industrial pipelines.

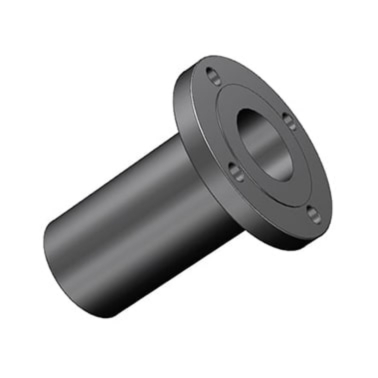

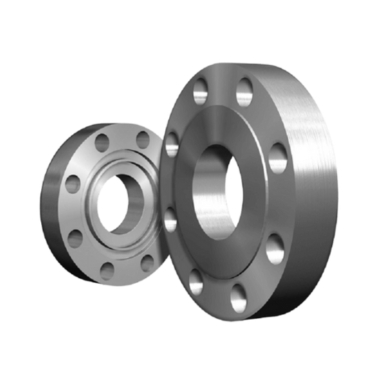

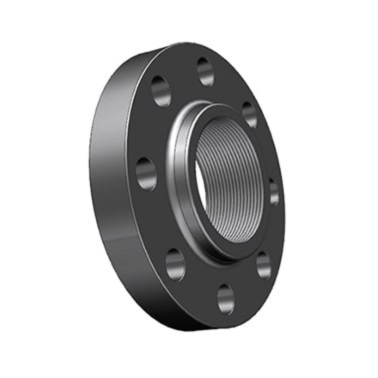

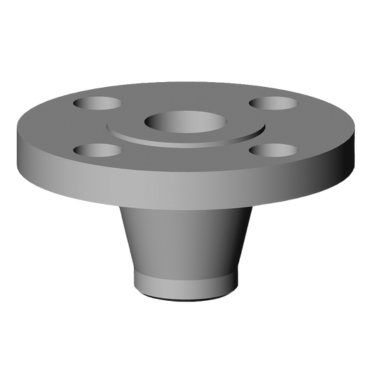

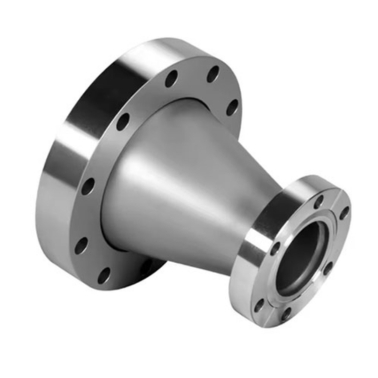

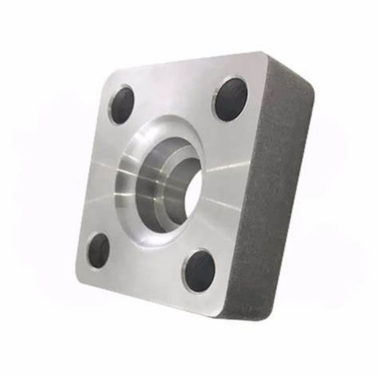

DIN Standard Flanges are available in different types, including weld neck flanges (DIN 2633, DIN 2634), blind flanges (DIN 2527), slip-on flanges (DIN 2502), and plate flanges (DIN 2573). DIN flanges are manufactured in materials like carbon steel, stainless steel, and alloy steel, ensuring durability and corrosion resistance. Commonly used in industries such as oil and gas, petrochemicals, water treatment, and power generation, DIN flanges offer reliable performance, precision, and compatibility with European piping standards.

Ample Alloys is a renowned manufacturer, supplier, and exporter of high-quality piping components, including DIN Standard flanges. With a strong focus on precision engineering and superior material quality. We offers a wide range of products in materials like stainless steel, carbon steel, alloy steel, duplex steel, nickel alloys, and other exotic metals, ensuring durability, corrosion resistance, and high performance under extreme conditions. Known for its commitment to customer satisfaction, We provides products that adhere to international standards like DIN. Backed by extensive industry experience, advanced infrastructure, and a skilled workforce, Ample Alloys has established itself as a trusted partner for reliable and cost-effective piping solutions worldwide.

DIN 2501-PN16, DIN 2502-PN25, DIN 2503-PN40, DIN 2631-PN6, DIN 2632-PN10 Pipe Flange, DIN 2527 blind flange, DIN 2573 plate flange, DIN 2634 weld neck flange, DIN 2502 slip-on flange, DIN PN40 forged flange

DIN Pipe Flange Specifications

Size Range

15mm ( 1/2" NPS ) up to 1200 mm ( 48" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

DIN Standard Flange (DIN 2573, 2576, 2501, 2502, 2503, 2631, 2632, 2633, 2634, 2635)

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

Table D, Table E, Table F, Table H, Table J.

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

DIN Flange - Dimensions & Weight

| Flange Nominal Diameter | Pressure Rating (PN) | |||||

|---|---|---|---|---|---|---|

| **Nominal BSP Pipe Size | PN6 | PN10 | PN16 | PN25 | PN40 | |

| DN 10 | 75 | 90 | 90 | 90 | 90 | O.D. |

| 3/8″ | 50 | 60 | 60 | 60 | 60 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 15 | 80 | 95 | 95 | 95 | 95 | O.D. |

| 1/2″ | 55 | 65 | 65 | 65 | 65 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 20 | 90 | 105 | 105 | 105 | 105 | O.D. |

| 3/4″ | 65 | 75 | 75 | 75 | 75 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 25 | 100 | 115 | 115 | 115 | 115 | O.D. |

| 1″ | 75 | 85 | 85 | 85 | 85 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 32 | 120 | 140 | 140 | 140 | 140 | O.D. |

| 1 1/4″ | 90 | 100 | 100 | 100 | 100 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 4 x 18 | 4 x 18 | # of holes x diam. of holes | |

| DN 40 | 130 | 150 | 150 | 150 | 150 | O.D. |

| 1 1/2″ | 100 | 110 | 110 | 110 | 110 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 4 x 18 | 4 x 18 | # of holes x diam. of holes | |

| DN 50 | 140 | 165 | 165 | 165 | 165 | O.D. |

| 2″ | 110 | 125 | 125 | 125 | 125 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 4 x 18 | 4 x 18 | # of holes x diam. of holes | |

| DN 65 | 160 | 185 | 185 | 185 | 185 | O.D. |

| 2 1/2″ | 130 | 145 | 145 | 145 | 145 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 8 x 18 | 8 x 18 | # of holes x diam. of holes | |

| DN 80 | 190 | 200 | 200 | 200 | 200 | O.D. |

| 3″ | 150 | 160 | 160 | 160 | 160 | PCD (bolt circle) |

| 4 x 18 | 8 x 18 | 8 x 18 | 8 x 18 | 8 x 18 | # of holes x diam. of holes | |

| DN 100 | 210 | 220 | 220 | 235 | 235 | O.D. |

| 4″ | 170 | 180 | 180 | 190 | 190 | PCD (bolt circle) |

| 4 x 18 | 8 x 18 | 8 x 18 | 8 x 22 | 8 x 22 | # of holes x diam. of holes | |

| DN 125 | 240 | 250 | 250 | 270 | 270 | O.D. |

| 5″ | 200 | 210 | 210 | 220 | 220 | PCD (bolt circle) |

| 8 x 18 | 8 x 18 | 8 x 18 | 8 x 26 | 8 x 26 | # of holes x diam. of holes | |

| DN 150 | 265 | 285 | 285 | 300 | 300 | O.D. |

| 6″ | 225 | 240 | 240 | 250 | 250 | PCD (bolt circle) |

| 8 x 18 | 8 x 22 | 8 x 22 | 8 x 26 | 8 x 26 | # of holes x diam. of holes | |

| DN 175 | 315 | 315 | 330 | 350 | O.D. | |

| 7″ | 270 | 270 | 280 | 295 | PCD (bolt circle) | |

| 8 x 22 | 8 x 22 | 12 x 26 | 12 x 30 | # of holes x diam. of holes | ||

| DN 200 | 320 | 340 | 340 | 360 | 375 | O.D. |

| 8″ | 280 | 295 | 295 | 310 | 320 | PCD (bolt circle) |

| 8 x 18 | 8 x 22 | 12 x 22 | 12 x 26 | 12 x 30 | # of holes x diam. of holes | |

| DN 250 | 375 | 395 | 405 | 425 | 450 | O.D. |

| 10″ | 335 | 350 | 355 | 370 | 385 | PCD (bolt circle) |

| 12 x 18 | 12 x 22 | 12 x 26 | 12 x 30 | 12 x 33 | # of holes x diam. of holes | |

| DN 300 | 440 | 445 | 460 | 485 | 515 | O.D. |

| 12″ | 395 | 400 | 410 | 430 | 450 | PCD (bolt circle) |

| 12 x 22 | 12 x 22 | 12 x 26 | 16 x 30 | 16 x 33 | # of holes x diam. of holes | |

| DN 350 | 490 | 505 | 520 | 555 | 580 | O.D. |

| 14″ | 445 | 460 | 470 | 490 | 510 | PCD (bolt circle) |

| 12 x 22 | 16 x 22 | 16 x 26 | 16 x 33 | 16 x 36 | # of holes x diam. of holes | |

| DN 400 | 540 | 565 | 580 | 620 | 660 | O.D. |

| 16″ | 495 | 515 | 525 | 550 | 585 | PCD (bolt circle) |

| 16 x 22 | 16 x 26 | 16 x 30 | 16 x 36 | 16 x 39 | # of holes x diam. of holes | |

| DN 500 | 645 | 670 | 715 | 730 | 755 | O.D. |

| 20″ | 600 | 620 | 650 | 660 | 670 | PCD (bolt circle) |

| 20 x 22 | 20 x 26 | 20 x 33 | 20 x 36 | 20 x 42 | # of holes x diam. of holes | |

| DN 600 | 755 | 780 | 840 | 845 | O.D. | |

| 24″ | 705 | 725 | 770 | 770 | PCD (bolt circle) | |

| 20 x 24 | 20 x 27 | 20 x 33 | 20 x 36 | # of holes x diam. of holes | ||

| Germany standard flange DIN 2573 for soldering or welding Nominall Pressure 6 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flansche, glatt zum löten oder schweißen DIN 2573 Nenndruck 6 | |||||||||||

| Brides plates a souder DIN 2573 pression nominale 6 | |||||||||||

| Pipe | Flange | Screws | Weight (7,85 Kg/dm3) |

||||||||

| Rated Diameter |

d1 | d5 | D | b | c | k | Holes | Thread | d2 | Kg | |

| ISO Series 1 | DIN Series 2 | ||||||||||

| 15 | – | 20 | 21 | 80 | 12 | 5 | 55 | 4 | M 10 | 11 | 0,41 |

| 21,3 | – | 22 | |||||||||

| 20 | – | 25 | 26 | 90 | 14 | 5 | 65 | 4 | M 10 | 11 | 0,60 |

| 26,9 | – | 27,6 | |||||||||

| 25 | – | 30 | 31 | 100 | 14 | 5 | 75 | 4 | M 10 | 11 | 0,74 |

| 33,7 | – | 34,4 | |||||||||

| 32 | – | 38 | 39 | 120 | 16 | 5 | 90 | 4 | M 12 | 14 | 1,19 |

| 42,4 | – | 43,1 | |||||||||

| 40 | – | 44,5 | 45,5 | 130 | 16 | 5 | 100 | 4 | M 12 | 14 | 1,39 |

| 48,3 | – | 49 | |||||||||

| 50 | – | 57 | 58,1 | 140 | 16 | 6 | 110 | 4 | M 12 | 14 | 1,53 |

| 60,3 | – | 61,1 | |||||||||

| 65 | 76,1 | – | 77,1 | 160 | 16 | 6 | 130 | 4 | M 12 | 14 | 1,89 |

| 80 | 88,9 | – | 90,3 | 190 | 18 | 7 | 150 | 4 | M 16 | 18 | 2,98 |

| 100 | – | 108 | 109,6 | 210 | 18 | 7 | 170 | 4 | M 16 | 18 | 3,46 |

| 114,3 | – | 115,9 | |||||||||

| 125 | – | 133 | 134,8 | 240 | 20 | 7 | 200 | 8 | M 16 | 18 | 4,60 |

| 139,7 | – | 141,6 | |||||||||

| 150 | – | 159 | 161,1 | 265 | 20 | 7 | 225 | 8 | M 16 | 18 | 5,22 |

| 168,3 | – | 170,5 | |||||||||

| 200 | 219,1 | – | 221,8 | 320 | 22 | 7 | 280 | 8 | M 16 | 18 | 7,15 |

| 250 | – | 267 | 270,2 | 375 | 24 | 7 | 335 | 12 | M 16 | 18 | 9,61 |

| 273 | – | 276,2 | |||||||||

| 300 | 323,9 | – | 327,6 | 440 | 24 | 7 | 395 | 12 | M 20 | 22 | 12,60 |

| 350 | 355,6 | – | 359,7 | 490 | 26 | 7 | 445 | 12 | M 20 | 22 | 15,60 |

| – | 368 | 372,2 | |||||||||

| 400 | 406,4 | – | 411 | 540 | 28 | 7 | 495 | 16 | M 20 | 22 | 18,40 |

| – | 419 | 423,7 | |||||||||

| (450)* | 457 | – | 462,5 | 595 | 30 | 7 | 550 | 16 | M 20 | 22 | 21,40 |

| 500 | 508 | – | 531,6 | 645 | 30 | 7 | 600 | 20 | M 20 | 22 | 24,60 |

| Germany standard flange DIN 2631 welding neck flanges; nominal pressure 6 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vorschweißflansche DIN 2631 Nenndruck 6 | ||||||||||||||||

| Brides à souder à collerette DIN 2631: pression nominale 6 | ||||||||||||||||

| Pipe | Flange | Neck | Raised face | Screws | Weight | |||||||||||

| (7,85 Kg/dm3) | ||||||||||||||||

| Rated | d1 | D | b | k | h1 | d3 | s | r | h2 | d4 | f | Holes | Thread | d2 | Kg | |

| Diameter | ISO Series | DIN Series | ||||||||||||||

| 15 | – | 20 | 80 | 12 | 55 | 30 | 28 | 2 | 4 | 6 | 40 | 2 | 4 | M 10 | 11 | 0,392 |

| 21,3 | – | 30 | ||||||||||||||

| 20 | – | 25 | 90 | 14 | 65 | 32 | 35 | 2,3 | 4 | 6 | 50 | 2 | 4 | M 10 | 11 | 0,592 |

| 26,9 | – | 38 | ||||||||||||||

| 25 | – | 30 | 100 | 14 | 75 | 35 | 40 | 2,6 | 4 | 6 | 60 | 2 | 4 | M 10 | 11 | 0,747 |

| 33,7 | – | 42 | ||||||||||||||

| 32 | – | 38 | 120 | 14 | 90 | 35 | 50 | 2,6 | 6 | 6 | 70 | 2 | 4 | M 12 | 14 | 1,05 |

| 42,4 | – | 55 | ||||||||||||||

| 40 | – | 44,5 | 130 | 14 | 100 | 38 | 58 | 2,6 | 6 | 7 | 80 | 3 | 4 | M 12 | 14 | 1,18 |

| 48,3 | – | 62 | ||||||||||||||

| 50 | – | 57 | 140 | 14 | 110 | 38 | 70 | 2,9 | 6 | 8 | 90 | 3 | 4 | M 12 | 14 | 1,34 |

| 60,3 | – | 74 | ||||||||||||||

| 65 | 76,1 | – | 160 | 14 | 130 | 38 | 88 | 2,9 | 6 | 9 | 110 | 3 | 4 | M 12 | 14 | 1,67 |

| 80 | 88,9 | – | 190 | 16 | 150 | 42 | 102 | 3,2 | 8 | 10 | 128 | 3 | 4 | M 16 | 18 | 2,71 |

| 100 | – | 108 | 210 | 16 | 170 | 45 | 122 | 3,6 | 8 | 10 | 148 | 3 | 4 | M 16 | 18 | 3,24 |

| 114,3 | 130 | |||||||||||||||

| 125 | – | 133 | 240 | 18 | 200 | 48 | 148 | 4 | 8 | 10 | 178 | 3 | 8 | M 16 | 18 | 4,49 |

| 139,7 | – | 155 | ||||||||||||||

| 150 | – | 159 | 265 | 18 | 225 | 48 | 172 | 4,5 | 10 | 12 | 202 | 3 | 8 | M 16 | 18 | 5,15 |

| 168,3 | – | 184 | ||||||||||||||

| 200 | 219,1 | – | 320 | 20 | 280 | 55 | 236 | 5,9 | 10 | 15 | 258 | 3 | 8 | M 16 | 18 | 7,78 |

| 250 | – | 267 | 375 | 22 | 335 | 60 | 282 | 6,3 | 12 | 15 | 312 | 3 | 12 | M 16 | 18 | 10,8 |

| 273 | – | 290 | ||||||||||||||

| 300 | 323,9 | – | 440 | 22 | 395 | 62 | 342 | 7,1 | 15 | 15 | 365 | 4 | 12 | M 20 | 22 | 14 |

| 350 | 355,6 | – | 490 | 22 | 445 | 62 | 385 | 7,1 | 12 | 15 | 415 | 4 | 12 | M 20 | 22 | 18,5 |

| – | 368 | 16,7 | ||||||||||||||

| 400 | 406,4 | – | 540 | 22 | 495 | 65 | 438 | 7,1 | 12 | 15 | 465 | 4 | 16 | M 20 | 22 | 21,2 |

| – | 419 | 19 | ||||||||||||||

| 500 | 508 | – | 645 | 24 | 600 | 68 | 538 | 7,1 | 12 | 15 | 570 | 4 | 20 | M 20 | 22 | 28,6 |

| 600 | 610 | – | 755 | 24 | 705 | 70 | 640 | 7,1 | 12 | 16 | 670 | 5 | 20 | M 24 | 26 | 31,5 |

| 700 | 711 | – | 860 | 24 | 810 | 70 | 740 | 7,1 | 12 | 16 | 775 | 5 | 24 | M 24 | 26 | 37,4 |

| 800 | 813 | – | 975 | 24 | 920 | 70 | 842 | 7,1 | 12 | 16 | 880 | 5 | 24 | M 27 | 30 | 46,1 |

| 900 | 914 | – | 1075 | 26 | 1020 | 70 | 942 | 7,1 | 12 | 16 | 980 | 5 | 24 | M 27 | 30 | 55,6 |

| 1000 | 1016 | – | 1175 | 26 | 1120 | 70 | 1045 | 7,1 | 16 | 16 | 1080 | 5 | 28 | M 27 | 30 | 61,9 |

| DIN 2565 PN 6 THREADED FLANGE | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rated Diameter |

Flange | Neck | Raised face | Screws | Weight (7,85 Kg/dm3) |

||||||||

| d1 | Thread | D | b | k | h1 | d3 | d4 | f | Holes | Thread | d2 | Kg | |

| 15 | 21,3 | R 1/2 | 80 | 12 | 55 | 20 | 30 | 40 | 2 | 4 | M 10 | 11 | 0,373 |

| 20 | 26,9 | R 3/4 | 90 | 14 | 65 | 24 | 40 | 50 | 2 | 4 | M 10 | 11 | 0,59 |

| 25 | 33,7 | R 1 | 100 | 14 | 75 | 24 | 50 | 60 | 2 | 4 | M 10 | 11 | 0,743 |

| 32 | 42,4 | R 1 1/4 | 120 | 14 | 90 | 26 | 60 | 70 | 2 | 4 | M 12 | 14 | 1,05 |

| 40 | 48,3 | R 1 1/2 | 130 | 14 | 100 | 26 | 70 | 80 | 3 | 4 | M 12 | 14 | 1,2 |

| 50 | 60,3 | R 2 | 140 | 14 | 110 | 28 | 80 | 90 | 3 | 4 | M 12 | 14 | 1,37 |

| 65 | 76,1 | R 2 1/2 | 160 | 14 | 130 | 32 | 100 | 110 | 3 | 4 | M 12 | 14 | 1,92 |

| 80 | 88,9 | R 3 | 190 | 16 | 150 | 34 | 110 | 128 | 3 | 4 | M 16 | 18 | 2,82 |

| 100 | 114,3 | R 4 | 210 | 16 | 170 | 38 | 130 | 148 | 3 | 4 | M 16 | 18 | 3,19 |

| 125 | 139,7 | R 5 | 240 | 18 | 200 | 40 | 160 | 178 | 3 | 8 | M 16 | 18 | 4,47 |

| 150 | 165,1 | R 6 | 265 | 18 | 225 | 44 | 185 | 202 | 3 | 8 | M 16 | 18 | 5,3 |

| DIN 2566 PN16 THREADED FLANGE | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rated Diameter |

Flange | Neck | Raised face | Screws | Weight (7,85 Kg/dm3) |

||||||||

| d1 | Thread | D | b | k | h1 | d3 | d4 | f | Holes | Thread | d2 | Kg | |

| 15 | 21,3 | R 1/2 | 95 | 14 | 65 | 20 | 35 | 45 | 2 | 4 | M 12 | 14 | 0,613 |

| 20 | 26,9 | R 3/4 | 105 | 16 | 75 | 24 | 45 | 58 | 2 | 4 | M 12 | 14 | 0,91 |

| 25 | 33,7 | R 1 | 115 | 16 | 85 | 24 | 52 | 68 | 2 | 4 | M 12 | 14 | 1,1 |

| 32 | 42,4 | R 1 1/4 | 140 | 16 | 100 | 26 | 60 | 78 | 2 | 4 | M 16 | 18 | 1,6 |

| 40 | 48,3 | R 1 1/2 | 150 | 16 | 110 | 26 | 70 | 88 | 3 | 4 | M 16 | 18 | 1,78 |

| 50 | 60,3 | R 2 | 165 | 18 | 125 | 28 | 85 | 102 | 3 | 4 | M 16 | 18 | 2,43 |

| 65 | 76,1 | R 2 1/2 | 185 | 18 | 145 | 32 | 105 | 122 | 3 | 4 | M 16 | 18 | 3,18 |

| 80 | 88,9 | R 3 | 200 | 20 | 160 | 34 | 118 | 138 | 3 | 8 | M 16 | 18 | 4,12 |

| 100 | 114,3 | R 4 | 220 | 20 | 180 | 38 | 140 | 158 | 3 | 8 | M 16 | 18 | 4,47 |

| 125 | 139,7 | R 5 | 250 | 22 | 210 | 40 | 168 | 188 | 3 | 8 | M 16 | 18 | 6,13 |

| 150 | 165,1 | R 6 | 285 | 22 | 240 | 44 | 195 | 212 | 3 | 8 | M 20 | 22 | 7,92 |

| Germany standard flange DIN 2527 Blind flange Nominal Pressure 6 to 100 | |||||||

|---|---|---|---|---|---|---|---|

| Blindflansche Nenndruck 6 bis 100 | |||||||

| Brides plaines, pressions nominales 6 à 100 | |||||||

| DIN 2527 PN6 BLIND FLANGE | |||||||

| Rated Diameter |

Flange | Screws | Weight (7,85 Kg/dm3) |

||||

| D | b | k | Number | Thread | d2 | Shape B | |

| Kg | |||||||

| 15 | 80 | 12 | 55 | 4 | M 10 | 11 | 0.44 |

| 20 | 90 | 14 | 65 | 0.66 | |||

| 25 | 100 | 14 | 75 | 0.83 | |||

| 32 | 120 | 14 | 90 | M 12 | 14 | 1.18 | |

| 40 | 130 | 14 | 100 | 1.39 | |||

| 50 | 140 | 14 | 110 | 1.63 | |||

| 65 | 160 | 14 | 130 | 2.15 | |||

| 80 | 190 | 16 | 150 | M 16 | 18 | 3.44 | |

| 100 | 210 | 16 | 170 | 4.22 | |||

| 125 | 240 | 18 | 200 | 8 | 6.11 | ||

| 150 | 265 | 18 | 225 | 7.51 | |||

| 200 | 320 | 20 | 280 | 12.31 | |||

| 250 | 375 | 22 | 335 | 12 | 18.54 | ||

| 300 | 440 | 22 | 395 | M 20 | 22 | 25.46 | |

| 350 | 490 | 22 | 445 | 31.77 | |||

| 400 | 540 | 22 | 495 | 16 | 38.49 | ||

| 500 | 645 | 24 | 600 | 20 | 60.10 | ||

| DIN 2527 PN10 BLIND FLANGE | |||||||

|---|---|---|---|---|---|---|---|

| Rated Diameter |

Flange | Screws | Weight (7,85 Kg/dm3) |

||||

| D | b | k | Number | Thread | d2 | Shape B | |

| Kg | |||||||

| 15 | 95 | 14 | 65 | 4 | M 12 | 14 | 0,72 |

| 20 | 105 | 16 | 75 | 1,01 | |||

| 25 | 115 | 16 | 85 | 1,23 | |||

| 32 | 140 | 16 | 100 | M 16 | 18 | 1,8 | |

| 40 | 150 | 16 | 110 | 2,09 | |||

| 50 | 165 | 18 | 125 | 2,88 | |||

| 65 | 185 | 18 | 145 | 3,66 | |||

| 80 | 200 | 20 | 160 | 4,77 | |||

| 100 | 220 | 20 | 180 | 8 | 5,65 | ||

| 125 | 250 | 22 | 210 | 8,42 | |||

| 150 | 285 | 22 | 240 | M 20 | 22 | 10,4 | |

| 200 | 340 | 24 | 295 | 16,5 | |||

| 250 | 395 | 26 | 350 | 12 | 24 | ||

| 300 | 445 | 26 | 400 | 30,9 | |||

| 350 | 505 | 26 | 460 | 16 | 40,6 | ||

| 400 | 565 | 26 | 515 | M 24 | 26 | 49,4 | |

| 500 | 670 | 28 | 620 | 20 | 75 | ||

| DIN 2527 PN16 BLIND FLANGE | |||||||

|---|---|---|---|---|---|---|---|

| Rated Diameter |

Flange | Screws | Weight (7,85 Kg/dm3) |

||||

| D | b | k | Number | Thread | d2 | Shape B | |

| Kg | |||||||

| 15 | 95 | 14 | 65 | 4 | M 12 | 14 | 0,72 |

| 20 | 105 | 16 | 75 | 1,01 | |||

| 25 | 115 | 16 | 85 | 1,23 | |||

| 32 | 140 | 16 | 100 | M 16 | 18 | 1,8 | |

| 40 | 150 | 16 | 110 | 2,09 | |||

| 50 | 165 | 18 | 125 | 2,88 | |||

| 65 | 185 | 18 | 145 | 3,66 | |||

| 80 | 200 | 20 | 160 | 8 | 4,77 | ||

| 100 | 220 | 20 | 180 | 5,65 | |||

| 125 | 250 | 22 | 210 | 8,42 | |||

| 150 | 285 | 22 | 240 | M 20 | 22 | 10,4 | |

| 200 | 340 | 24 | 295 | 12 | 16,1 | ||

| 250 | 405 | 26 | 355 | M 24 | 26 | 24,9 | |

| 300 | 460 | 28 | 410 | 35,1 | |||

| 350 | 520 | 30 | 470 | 16 | 47,8 | ||

| 400 | 580 | 32 | 525 | M 27 | 30 | 63,5 | |

| 500 | 715 | 36 | 650 | 20 | M 30 | 33 | 102 |

| Germany standard flange DIN 2642 lapped flange; nominal pressure 10 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lose Flansche Vorschweißbördel Glatte Bunde DIN 2642 Nenndruck 10 | |||||||||||||

| Brides tournantes: pression nominale 10 | |||||||||||||

| Pipe | Flange | Screws | Weight (7,85 Kg/dm3) |

||||||||||

| Rated Diameter |

d1 | D | d6 | b | k | e | Holes | Thread | d2 | Kg | |||

| ISO Series 1 |

DIN Series 2 |

||||||||||||

| 15 | – | 20 | 95 | 22 | 14 | 65 | 3 | 4 | M 12 | 14 | 0,689 | ||

| 21,3 | – | 24 | |||||||||||

| 20 | – | 25 | 105 | 28 | 14 | 75 | 3 | 4 | M 12 | 14 | 0,806 | ||

| 26,9 | – | 30 | |||||||||||

| 25 | – | 30 | 115 | 33 | 16 | 85 | 4 | 4 | M 12 | 14 | 1,11 | ||

| 33,7 | – | 36 | |||||||||||

| 32 | – | 38 | 140 | 42 | 16 | 100 | 4 | 4 | M 16 | 18 | 1,64 | ||

| 42,4 | – | 46 | |||||||||||

| 40 | – | 44,5 | 150 | 50 | 16 | 110 | 4 | 4 | M 16 | 18 | 1,86 | ||

| 48,3 | – | 54 | |||||||||||

| 50 | – | 57 | 165 | 62 | 16 | 125 | 5 | 4 | M 16 | 18 | 2,2 | ||

| 60,3 | – | 65 | |||||||||||

| 65 | 76,1 | – | 185 | 81 | 16 | 145 | 5 | 4 | M 16 | 18 | 2,62 | ||

| 80 | 88,9 | – | 200 | 94 | 18 | 160 | 5 | 8 | M 16 | 18 | 3,32 | ||

| 100 | – | 108 | 220 | 113 | 18 | 180 | 5 | 8 | M 16 | 18 | 3,67 | ||

| 114,3 | – | 119 | |||||||||||

| 125 | – | 133 | 250 | 138 | 18 | 210 | 5 | 8 | M 16 | 18 | 4,54 | ||

| 139,7 | – | 145 | |||||||||||

| 150 | – | 159 | 285 | 164 | 18 | 240 | 5 | 8 | M 20 | 22 | 5,6 | ||

| 168,3 | – | 173 | |||||||||||

| 200 | 219,1 | – | 340 | 225 | 20 | 295 | 5 | 8 | M 20 | 22 | 7,46 | ||

| 250 | – | 267 | 395 | 273 | 22 | 350 | 5 | 12 | M 20 | 22 | 10,3 | ||

| 273 | – | 279 | |||||||||||

| 300 | 323,9 | – | 445 | 329 | 26 | 400 | 5 | 12 | M 20 | 22 | 14 | ||

| 350 | 355,6 | – | 505 | 362 | 28 | 460 | 6 | 16 | M 20 | 22 | 18,5 | ||

| – | 368 | 374 | |||||||||||

| 400 | 406,4 | – | 565 | 413 | 32 | 515 | 6 | 16 | M 24 | 26 | 25 | ||

| – | 419 | 426 | |||||||||||

| (450) | 457 | – | 615 | 467 | 38 | 565 | 6 | 20 | M 24 | 26 | 30,6 | ||

| 500 | 508 | – | 670 | 517 | 38 | 620 | 6 | 20 | M 24 | 26 | 37 | ||

| 600 | 610 | – | 780 | 618 | 44 | 725 | 7 | 20 | M 27 | 30 | 56,3 | ||

| 700 | 711 | – | 895 | 721 | 50 | 840 | 7 | 24 | M 27 | 30 | 80,4 | ||

| 800 | 813 | – | 1015 | 824 | 56 | 950 | 7 | 24 | M 30 | 33 | 113,2 | ||

DIN Flange Standards

DIN Flange Standards refer to the specifications established by the Deutsches Institut für Normung (DIN), which define the dimensions, materials, pressure ratings, and applications of flanges. These standards ensure consistency, quality, and compatibility in piping systems across industries. Below are some commonly used DIN Flange Standards:

These standards specify different pressure classes, such as PN6, PN10, PN16, PN25, PN40, and PN100, to accommodate varying pressure and temperature requirements. DIN flanges are manufactured in materials like carbon steel, stainless steel, and alloy steel, ensuring durability, corrosion resistance, and versatility in industrial applications. DIN flange standards are widely adopted in European and global markets for their precision, reliability, and adherence to strict quality norms.

- DIN 2501 - General specifications for flanges, including dimensions and tolerances.

- DIN 2527 - Blind flanges (used to close pipe ends).

- DIN 2573 - Plate flanges for low-pressure applications (PN6).

- DIN 2576 - Slip-on flanges for medium-pressure systems (PN10).

- DIN 2631 - Weld neck flanges for PN6 pressure rating.

- DIN 2632 - Weld neck flanges for PN10 pressure rating.

- DIN 2633 - Weld neck flanges for PN16 pressure rating.

- DIN 2634 - Weld neck flanges for PN25 pressure rating.

- DIN 2635 - Weld neck flanges for PN40 pressure rating.

- DIN 86029 - Flanges for shipbuilding and marine piping systems.

Why Ample Alloys For DIN Pipe Flanges!

Ample Alloys stands out as a trusted and leading manufacturer, supplier, and exporter of DIN Pipe Flanges, offering unmatched quality, reliability, and customer satisfaction.

Extensive Product Range

Ample Alloys provides a comprehensive range of DIN flanges, including weld neck flanges, slip-on flanges, blind flanges, plate flanges, and more, catering to pressure classes such as PN6, PN10, PN16, PN25, PN40, and PN100.

Adherence to Standards

Ample Alloys strictly adheres to DIN standards and other international norms like ASTM, ASME, EN, and ISO, ensuring products meet precise specifications and global quality requirements.

Advanced Manufacturing Facilities

Equipped with state-of-the-art infrastructure and advanced machinery, Ample Alloys delivers flanges with accurate dimensions, perfect finishing, and strict quality control.

Global Supply Network

With a robust distribution network, Ample Alloys efficiently supplies DIN flanges to clients worldwide, ensuring timely deliveries and excellent service.

- Weld Neck Flange (DIN 2631, DIN 2633, DIN 2634, DIN 2635)

- Slip-On Flange (DIN 2576, DIN 2502)

- Blind Flange (DIN 2527)

- Plate Flange (DIN 2573)

DIN flanges follow the German standard with pressure ratings like PN6, PN10, PN16, etc., while ANSI flanges follow the ASME/ANSI B16.5 standard with pressure classes such as 150#, 300#, 600#, and so on. The dimensions and drilling patterns also differ between the two.

PN stands for Pressure Nominal, indicating the maximum allowable working pressure of the flange in bars at a specific temperature. For example, PN16 denotes a pressure rating of 16 bars.