API 6A Flange, API 6B Flange, API 6BX Flange

API 6A Flanges are specialized flanged connections used in wellhead and Christmas tree equipment within the oil and gas industry. Manufactured according to the API 6A standard, these flanges are designed to handle high-pressure, high-temperature conditions typically encountered in upstream operations. They are primarily used to ensure a reliable seal between components in drilling and production systems.

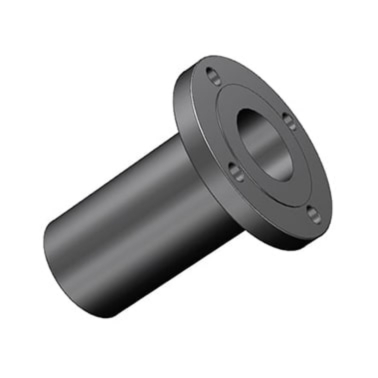

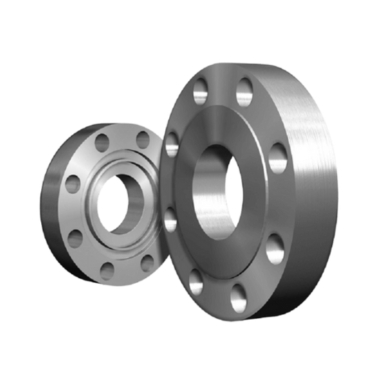

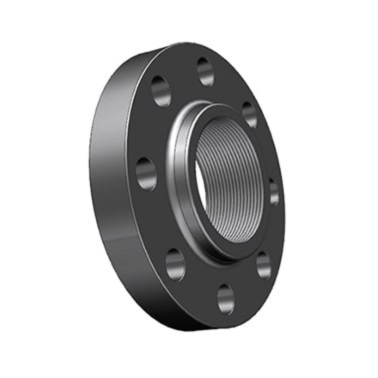

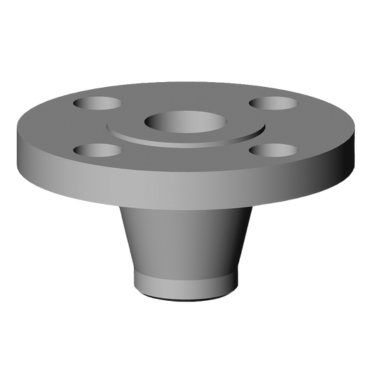

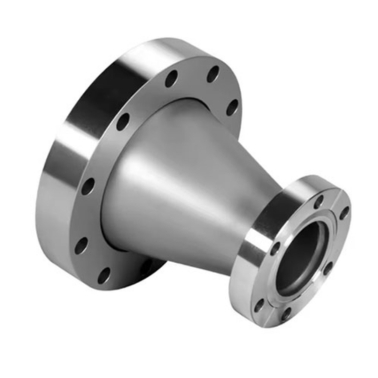

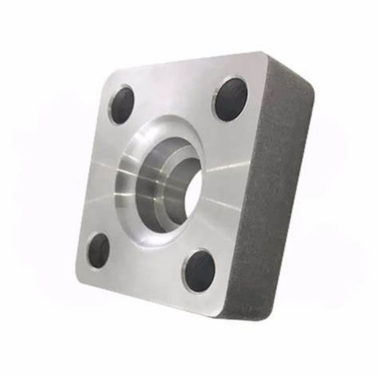

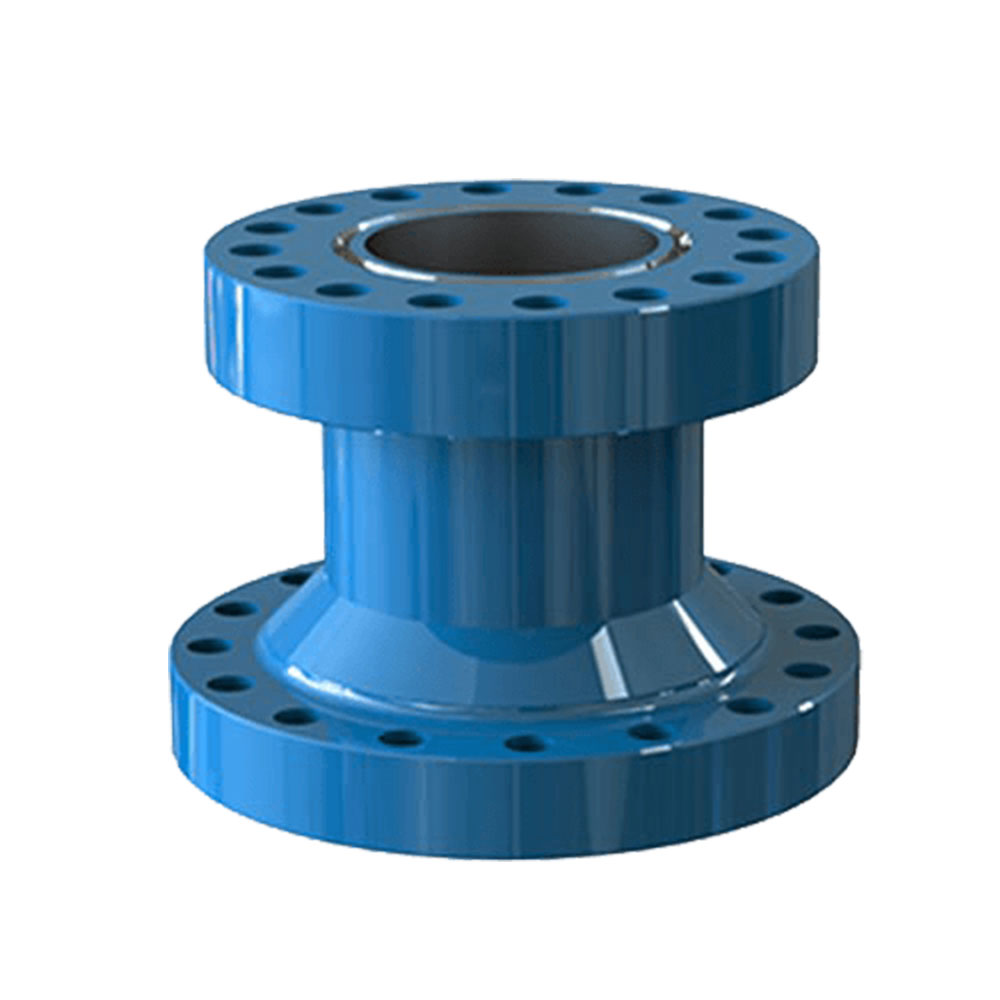

API 6A flanges come in various types, including hubbed, flanged, and blind flanges, with pressure ratings ranging from 2,000 psi to 20,000 psi. The materials used for API 6A flanges typically include carbon steel and alloy steel, selected for their ability to withstand extreme pressures, harsh environments, and corrosive fluids. The flanges are available in various sizes and pressure classes to meet the specific needs of different oil and gas applications. API 6A flanges are essential for maintaining safe and secure connections in critical equipment, offering high integrity and resistance to external stress, making them crucial components in the oil and gas industry.

Ample Alloys is a trusted supplier of API 6A flanges, offering high-quality products designed for the demanding conditions of the oil and gas industry. With strict adherence to API 6A standards, they provide a wide range of materials such as carbon steel, alloy steel, and stainless steel to meet various application needs. Their flanges are precision-engineered for durability, reliability, and excellent performance in high-pressure environments. We also offers customization options, competitive pricing, and timely delivery, making them a reliable choice for your API 6A flange requirements.

High-pressure flanges API 6A, API 6A flange bolting, API 6A flange facing, API 6A carbon steel flanges, API 6A stainless steel flanges, API 6A flanges for drilling

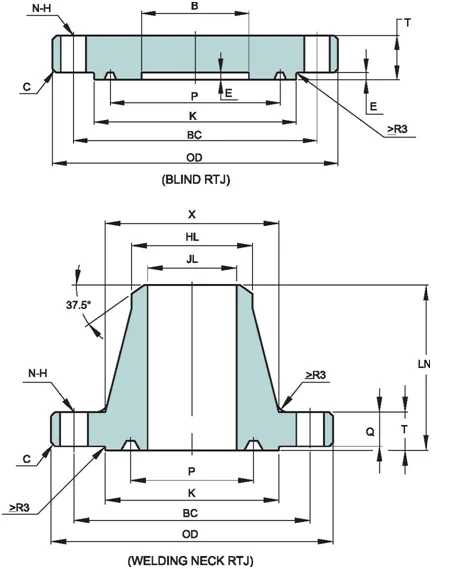

API 6A Flange Specifications

Size Range

DN 46 (NPS 1-13/16") to DN 345 (NPS 13-5/8")

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

American Petroleum Institute (API) API 6A, 6bx, 4130 , 6bx

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

2,000 psi, 3,000 psi, 5,000 psi, 10,000 psi, 15,000 psi, 20,000 psi

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

| Size | B | OD | C (MAX.) | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | Ring Number |

| R or RX | ||||||||||||||||

| 2 1/16˝ 2 9/16˝ 3 1/8˝ 4 1/16˝ 5 1/8˝ 7 1/16˝ 9˝ 11˝ 13 5/8˝ 16 3/4˝ 21 1/4˝ | 53.2 65.9 81.8 108.7 131.0 181.8 229.4 280.2 346.9 426.2 540.5 | 165 190 210 275 330 355 420 510 560 685 815 | 3 3 3 3 3 6 6 6 6 6 6 | 108 127 146 175 210 241 302 356 413 508 635 | 82.55 101.60 123.83 149.23 180.98 211.15 269.88 323.85 381.00 469.90 584.20 | 7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9 9.7 | 33.4 36.6 39.7 46.1 52.4 55.6 63.5 71.5 74.7 84.2 98.5 | 25.4 28.6 31.8 38.1 44.5 47.6 55.6 63.5 66.7 76.2 88.9 | 84 100 117 152 189 222 273 343 400 495 610 | 127 149.2 168.3 215.9 266.7 292.1 349.3 431.8 489 603.2 723.9 | 8 8 8 8 8 12 12 16 20 20 24 | 20 23 23 26 29 29 32 35 35 42 45 | 81 88 91 110 122 126 141 160 — | 60.3 73.0 88.9 114.3 141.3 168.3 219.1 273.0 — | 53.3 63.5 78.7 103.1 122.9 147.1 199.1 248.4 — | 23 26 31 37 41 45 49 53 57 65 73 |

| Size | B | OD | C (MAX.) | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | Ring Number |

| R or RX | ||||||||||||||||

| 2 1/16˝ 2 9/16˝ 3 1/8˝ 4 1/16˝ 5 1/8˝ 7 1/16˝ 9˝ 11˝ 13 5/8˝ 16 3/4˝ 20 3/4˝ | 53.2 65.9 81.8 108.7 131.0 181.8 229.4 280.2 346.9 426.2 527.8 | 215 245 240 290 350 380 470 545 610 705 855 | 3 3 3 3 3 6 6 6 6 6 6 | 124 137 156 181 216 241 308 362 419 524 648 | 95.25 107.95 123.83 149.23 180.98 211.15 269.88 323.85 381.00 469.90 584.20 | 7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9 11.2 12.7 | 46.1 49.3 46.1 52.4 58.8 63.5 71.5 77.8 87.4 100.1 120.7 | 38.1 41.3 38.1 44.4 50.8 55.6 63.5 69.9 79.4 88.9 108 | 104.8 123.8 127.0 158.8 190.5 235.0 298.5 368.3 419.1 508.0 622.3 | 165.1 190.5 190.5 235.0 279.4 317.5 393.7 469.9 533.4 616.0 749.3 | 8 8 8 8 8 12 12 16 20 20 20 | 26 29 26 32 35 32 39 39 39 45 54 | 109.6 112.7 109.5 122.2 134.9 147.6 169.9 192.1 — | 60.3 73.0 88.9 114.3 141.3 168.3 219.1 273 — | 50.0 59.7 74.4 98.0 122.9 147.1 189.7 237.2 — | 24 27 31 37 41 45 49 53 57 66 74 |

| Size | B | OD | C (MAX.) | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | Ring Number |

| R or RX | ||||||||||||||||

| 2 1/16˝ 2 9/16˝ 3 1/8˝ 4 1/16˝ 5 1/8˝ 7 1/16˝ 9˝ 11˝ | 53.2 65.9 81.8 108.7 131.0 181.8 229.4 280.2 | 215 245 265 310 375 395 485 585 | 3 3 3 3 3 6 6 6 | 124 137 168 194 229 248 318 371 | 95.25 107.95 136.53 161.93 193.68 211.15 269.88 323.85 | 7.9 7.9 7.9 7.9 7.9 9.7 11.2 11.2 | 46.1 49.3 55.6 62 81 92.1 103.2 119.1 | 38.1 41.3 47.7 54 73.1 82.6 92.1 108 | 104.8 123.8 133.3 161.9 196.8 228.6 292.1 368.3 | 165.1 190.5 203.2 241.3 292.1 317.5 393.7 482.6 | 8 8 8 8 8 12 12 12 | 26 29 32 35 42 39 45 51 | 109.5 112.7 125.4 131.8 163.5 181 223.8 265.1 | 60.3 73.0 88.9 114.3 141.3 168.3 219.1 273.1 | 43.7 54.9 67.5 88.1 110.3 132.6 173.8 216.7 | 24 27 35 39 44 46 50 54 |

API 6A Pipe Flanges Standards

API 6A, established by the American Petroleum Institute, sets the industry standard for flanged connections used in wellhead and Christmas tree equipment within the oil and gas industry. The standard covers the design, manufacturing, testing, and material specifications for flanges to ensure safety, performance, and durability under high-pressure, high-temperature conditions.

- API Standards (Oil & Gas)

- API 6A – Wellhead and Christmas Tree Equipment Flanges.

- API 605 – Large-Diameter Carbon Steel Flanges (merged into ASME B16.47 Series B).

Why Ample Alloys For API Flanges!

Choose Ample Alloys for your API 6A flanges and experience reliable, high-performance flanges designed to meet the demanding standards of the oil and gas industry.

Commitment to Quality

Strict adherence to API 6A standards, ensuring high-pressure and high-temperature performance, with rigorous quality control.

Customization Options

Flexible sizes, pressure ratings, and material grades to meet unique project requirements.

Expert Support

A team of engineers and technical specialists available for guidance and technical support throughout the process.

Timely Delivery

Reliable global supply chain to ensure on-time delivery and project schedule adherence.

API 6A flanges can have different flange facings such as raised face or flat face, which affect the sealing capabilities and pressure containment of the connection.

API 6A flanges undergo stringent testing procedures, including hydrostatic testing, pressure testing, and visual inspection to verify the strength, integrity, and leak-proof performance under pressure.

Yes, API 6A flanges are designed to be compatible with other global standards such as ASME B16.5, DIN, and ISO for cross-compliance across different industries.