JIS B2220 5k, 2k, 10k, 16k Flange

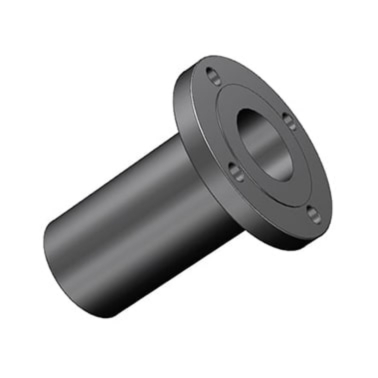

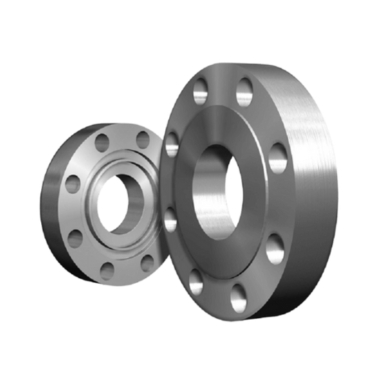

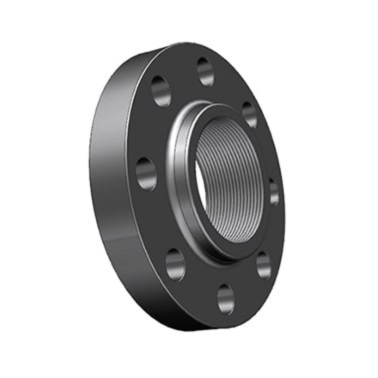

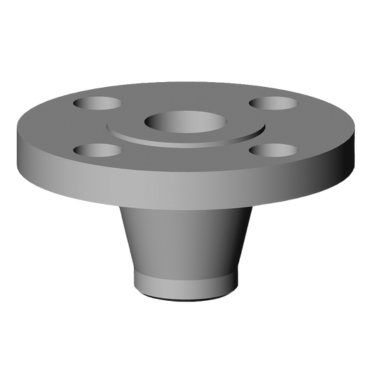

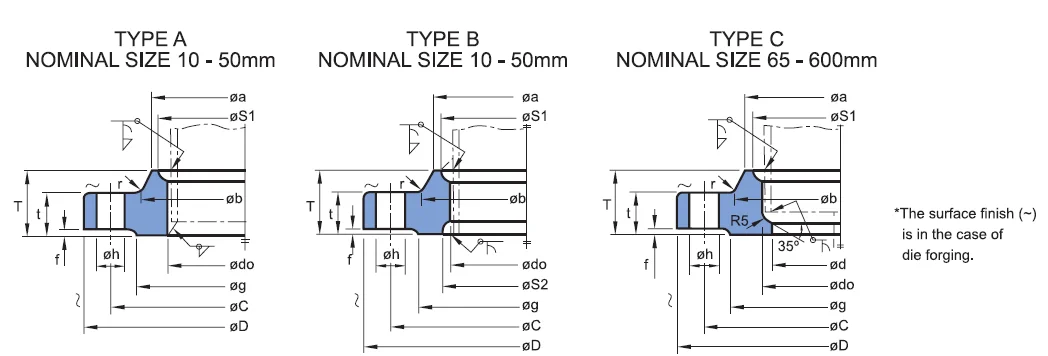

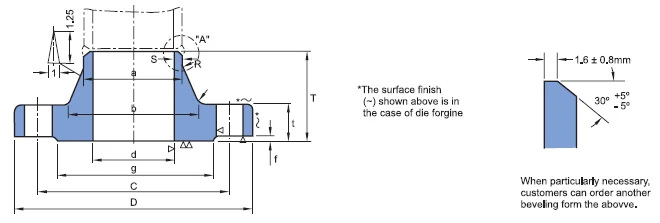

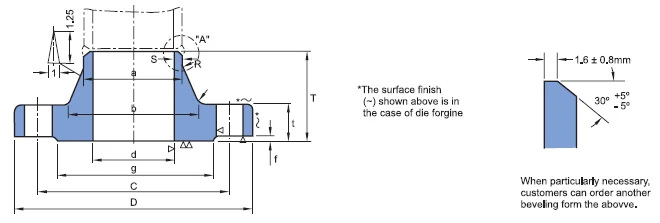

JIS B2220 Flanges are widely recognized for their adherence to Japanese Industrial Standards, ensuring reliable and efficient connections in piping systems. Manufactured in accordance with the JIS B2220 standard, these flanges are available in multiple types, such as slip-on, weld neck, blind, socket weld, and threaded, making them suitable for a wide range of applications.

JIS B2220 flanges are produced in materials like carbon steel, stainless steel, and alloy steel to ensure durability, corrosion resistance, and high performance under varying pressure and temperature conditions. They are available in pressure ratings such as PN10, PN16, and PN20, with precise dimensions that meet stringent quality standards. These flanges are often used in both domestic and industrial applications, providing reliable solutions for Japanese-standard piping systems.

Ample Alloys is a name synonymous with excellence in the industrial sector. Offering a broad range of JIS B2220 flanges, the company is dedicated to meeting the dynamic demands of industries worldwide. Our products, manufactured with state-of-the-art technology and superior raw materials, are known for their precision, durability, and compliance with global standards. Ample Alloys’ commitment to delivering innovative solutions ensures we remain a trusted partner for complex and challenging projects.

JIS B2220 Welding Neck Flange, JIS B2220 Blind Flange, JIS B2220 slip-on flange, JIS B2220 socket weld flange, JIS B2220 threaded flange, JIS B2220 forged flange, JIS B2220 ductile iron flange, JIS B2220 flange with coatings

JIS b2220 Flange Specifications

Size Range

15mm ( 1/2" NPS ) up to 1200 mm ( 48" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

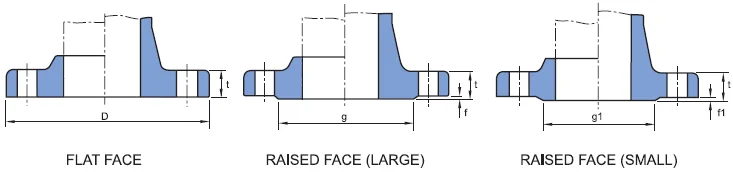

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

Japanese Industrial Standard (JIS B2220)

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

5K, 10K, 16K, 20K, 30K

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

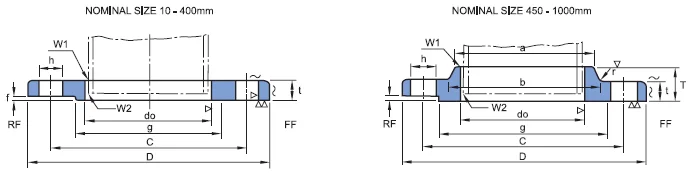

| Nominal Dia. of Flange | Outside Dia. of Flange D | Sectional Dimensions of flange | Nominal Bolt Size | Welding | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. of Bolt Circle C | Dia. Of raised Face g | Inside Dia. Of Flange do | Outside Dia. Of Applicable pipe | t | T | Dia. of Hub | Radius r | Raised Face f | Hole Dia. H | Number of Bolt Holes | ||||||

| a | b | W1 | W2 | |||||||||||||

| 10 | 75 | 55 | 39 | 17.8 | 17.3 | 9 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 2.5 |

| 15 | 80 | 60 | 44 | 22.2 | 21.7 | 9 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 3 |

| 20 | 85 | 65 | 49 | 27.7 | 27.2 | 10 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 3 |

| 25 | 95 | 75 | 59 | 34.5 | 34 | 10 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 3 |

| 32 | 115 | 90 | 70 | 43.2 | 42.7 | 12 | – | – | – | – | 2 | 15 | 4 | M12 | 6 | 3 |

| 40 | 120 | 95 | 75 | 49.1 | 48.6 | 12 | – | – | – | – | 2 | 15 | 4 | M12 | 6 | 3 |

| 50 | 130 | 105 | 85 | 61.1 | 60.5 | 14 | – | – | – | – | 2 | 15 | 4 | M12 | 6 | 3 |

| 65 | 155 | 130 | 110 | 77.1 | 76.3 | 14 | – | – | – | – | 2 | 15 | 4 | M12 | 6 | 4 |

| 80 | 180 | 145 | 121 | 90 | 89.1 | 14 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 4 |

| 90 | 190 | 155 | 131 | 102.6 | 101.6 | 14 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 4 |

| 100 | 200 | 165 | 141 | 115.4 | 114.3 | 16 | – | – | – | – | 2 | 19 | 8 | M16 | 7 | 4 |

| 125 | 235 | 200 | 176 | 141.2 | 139.8 | 16 | – | – | – | – | 2 | 19 | 8 | M16 | 7 | 4 |

| 150 | 265 | 230 | 206 | 166.6 | 165.2 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 7 | 5 |

| 175 | 300 | 260 | 232 | 192.1 | 190.7 | 18 | – | – | – | – | 2 | 23 | 8 | M20 | 7.5 | 5 |

| 200 | 320 | 280 | 252 | 218 | 216.3 | 20 | – | – | – | – | 2 | 23 | 8 | M20 | 8.5 | 6 |

| 225 | 345 | 305 | 277 | 243.7 | 241.8 | 20 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 6 |

| 250 | 385 | 345 | 317 | 269.5 | 267.4 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 10 | 6 |

| 300 | 430 | 390 | 360 | 321 | 318.5 | 22 | – | – | – | – | 3 | 23 | 12 | M20 | 10 | 6 |

| 350 | 480 | 435 | 403 | 358.1 | 355.6 | 24 | – | – | – | – | 3 | 25 | 12 | M22 | 12 | 7 |

| 400 | 540 | 495 | 463 | 409 | 406.4 | 24 | – | – | – | – | 3 | 25 | 16 | M22 | 12 | 7 |

| 450 | 605 | 555 | 523 | 460 | 457.2 | 24 | 40 | 495 | 500 | 5 | 3 | 25 | 16 | M22 | 12 | 7 |

| 500 | 655 | 605 | 573 | 511 | 508 | 24 | 40 | 546 | 552 | 5 | 3 | 25 | 20 | M22 | 12 | 7 |

| 550 | 720 | 665 | 630 | 562 | 558.8 | 26 | 42 | 597 | 603 | 5 | 3 | 27 | 20 | M24 | 12 | 7 |

| 600 | 770 | 715 | 680 | 613 | 609.6 | 26 | 44 | 648 | 654 | 5 | 3 | 27 | 20 | M24 | 12 | 7 |

| 650 | 825 | 770 | 735 | 664 | 660.4 | 26 | 48 | 702 | 708 | 5 | 3 | 27 | 24 | M24 | 12 | 7 |

| 700 | 875 | 820 | 785 | 715 | 711.2 | 26 | 48 | 751 | 758 | 5 | 3 | 27 | 24 | M24 | 12 | 7 |

| 750 | 945 | 880 | 840 | 766 | 762 | 28 | 52 | 802 | 810 | 5 | 3 | 33 | 24 | M30 | 12 | 7 |

| 800 | 995 | 930 | 890 | 817 | 812.8 | 28 | 52 | 854 | 862 | 5 | 3 | 33 | 24 | M30 | 13 | 8 |

| 850 | 1045 | 980 | 940 | 868 | 863.6 | 28 | 54 | 904 | 912 | 5 | 3 | 33 | 24 | M30 | 13 | 8 |

| 900 | 1095 | 1030 | 990 | 919 | 914.4 | 30 | 56 | 956 | 964 | 5 | 3 | 33 | 24 | M30 | 13 | 8 |

| 1000 | 1195 | 1130 | 1090 | 1021 | 1016 | 32 | 60 | 1058 | 1066 | 5 | 3 | 33 | 28 | M30 | 14 | 9 |

| *(1100) | 1305 | 1240 | 1200 | 1123 | 1117.6 | 32 | – | – | – | – | 3 | 33 | 28 | M30 | ||

| *1200 | 1420 | 1350 | 1305 | 1225 | 1219.2 | 34 | – | – | – | – | 3 | 33 | 32 | M30 | ||

| *1350 | 1575 | 1505 | 1460 | – | 1371.6 | 34 | – | – | – | – | 3 | 33 | 32 | M30 | ||

| *1500 | 1730 | 1660 | 1615 | – | 1524 | 36 | – | – | – | – | 3 | 33 | 36 | M30 | ||

| Nominal Dia. of Flange | Outside Dia. of Flange D | Sectional Dimensions of flange | Nominal Bolt Size | Welding | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. of Bolt Circle C | Dia. Of raised Face g | Inside Dia. Of Flange do | Outside Dia. Of Applicable pipe | t | T | Dia. of Hub | Radius r | Raised Face f | Hole Dia. H | Number of Bolt Holes | ||||||

| a | b | W1 | W2 | |||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 12 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 2.5 |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 12 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 3 |

| 20 | 100 | 75 | 56 | 27.7 | 27.2 | 14 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 3 |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 14 | – | – | – | – | 1 | 19 | 4 | M16 | 5 | 3 |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 65 | 175 | 140 | 116 | 77.1 | 76.3 | 18 | – | – | – | – | 2 | 19 | 4 | M16 | 6.5 | 4 |

| 80 | 185 | 150 | 126 | 90 | 89.1 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 6.5 | 4 |

| -90 | 195 | 160 | 136 | 102.6 | 101.6 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 6.5 | 4 |

| 100 | 210 | 175 | 151 | 115.4 | 114.3 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 7 | 4 |

| 125 | 250 | 210 | 182 | 141.2 | 139.8 | 20 | – | – | – | – | 2 | 23 | 8 | M20 | 7.5 | 4 |

| 150 | 280 | 240 | 212 | 166.6 | 165.2 | 22 | – | – | – | – | 2 | 23 | 8 | M20 | 8 | 5 |

| -175 | 305 | 265 | 237 | 192.1 | 190.7 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 5 |

| 200 | 330 | 290 | 262 | 218 | 216.3 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 6 |

| -255 | 350 | 310 | 282 | 243.7 | 241.8 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 6 |

| 250 | 400 | 355 | 324 | 269.5 | 267.4 | 24 | 36 | 288 | 292 | 6 | 2 | 25 | 12 | M22 | 10 | 6 |

| 300 | 445 | 400 | 368 | 321 | 318.5 | 24 | 38 | 340 | 346 | 6 | 3 | 25 | 16 | M22 | 10 | 6 |

| 350 | 490 | 445 | 413 | 358.1 | 355.6 | 26 | 42 | 380 | 386 | 6 | 3 | 25 | 16 | M22 | 12 | 7 |

| 400 | 560 | 510 | 475 | 409 | 406.4 | 28 | 44 | 436 | 442 | 6 | 3 | 27 | 16 | M24 | 12 | 7 |

| 450 | 620 | 565 | 530 | 460 | 457.2 | 30 | 48 | 496 | 502 | 6 | 3 | 27 | 20 | M24 | 14 | 8 |

| 500 | 675 | 620 | 585 | 511 | 508 | 30 | 48 | 548 | 554 | 6 | 3 | 27 | 20 | M24 | 14 | 8 |

| 550 | 745 | 680 | 640 | 562 | 558.8 | 32 | 52 | 604 | 610 | 6 | 3 | 33 | 20 | M30 | 15 | 9 |

| 600 | 795 | 730 | 690 | 613 | 609.6 | 32 | 52 | 656 | 662 | 6 | 3 | 33 | 24 | M30 | 16 | 10 |

| 650 | 845 | 780 | 740 | 664 | 660.4 | 34 | 56 | 706 | 712 | 6 | 3 | 33 | 24 | M30 | 16 | 10 |

| 700 | 905 | 840 | 800 | 715 | 711.2 | 34 | 58 | 762 | 770 | 6 | 3 | 33 | 24 | M30 | 17 | 10 |

| 750 | 970 | 900 | 855 | 766 | 762 | 36 | 62 | 816 | 824 | 6 | 3 | 33 | 24 | M30 | 18 | 11 |

| 800 | 1020 | 950 | 905 | 817 | 812.8 | 36 | 64 | 868 | 876 | 6 | 3 | 33 | 28 | M30 | 19 | 12 |

| -850 | 1070 | 1000 | 955 | 868 | 863.6 | 36 | 66 | 920 | 928 | 6 | 3 | 33 | 28 | M30 | 19 | 12 |

| 900 | 1120 | 1050 | 1005 | 919 | 914.4 | 38 | 70 | 971 | 979 | 6 | 3 | 33 | 28 | M30 | 22 | 14 |

| 1000 | 1235 | 1160 | 1110 | 1021 | 1016 | 40 | 74 | 1073 | 1081 | 6 | 3 | 39 | 28 | M36 | 22 | 14 |

| *(1100) | 1345 | 1270 | 1220 | 1123 | 1117.6 | 42 | – | – | – | – | 3 | 39 | 28 | M36 | ||

| *1200 | 1465 | 1380 | 1325 | 1225 | 1219.2 | 44 | – | – | – | – | 3 | 39 | 32 | M36 | ||

| *1350 | 1630 | 1540 | 1480 | – | 1371.6 | 48 | – | – | – | – | 3 | 45 | 36 | M42 | ||

| *1500 | 1795 | 1700 | 1635 | – | 1524 | 50 | – | – | – | – | 3 | 45 | 40 | M42 | ||

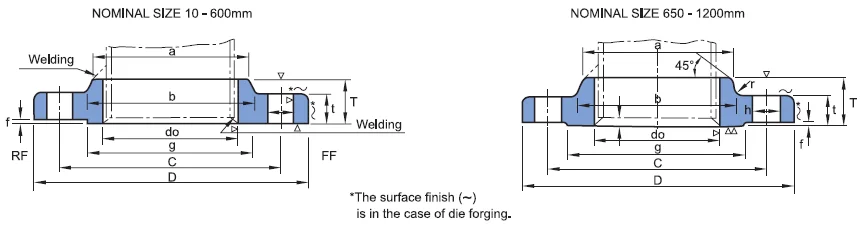

| Nominal Dia. of Flange | Outside Dia. of Flange D | Sectional Dimensions of flange | Nominal Bolt Size | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. of Bolt Circle C | Dia. Of raised Face g | Inside Dia. Of Flange do | Outside Dia. Of Applicable pipe | t | T | Dia. of Hub | Radius r | Raised Face f | Hole Dia. H | Number of Bolt Holes | ||||

| a | b | |||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 12 | 16 | 26 | 28 | 4 | 1 | 15 | 4 | M12 |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 12 | 16 | 30 | 32 | 4 | 1 | 15 | 4 | M12 |

| 20 | 100 | 75 | 56 | 27.7 | 27..2 | 14 | 20 | 38 | 42 | 4 | 1 | 15 | 4 | M12 |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 14 | 20 | 46 | 50 | 4 | 1 | 19 | 4 | M16 |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 16 | 22 | 56 | 60 | 5 | 2 | 19 | 4 | M16 |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 16 | 24 | 62 | 66 | 5 | 2 | 19 | 4 | M16 |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 16 | 24 | 76 | 80 | 5 | 2 | 19 | 8 | M16 |

| 65 | 175 | 140 | 116 | 77.1 | 76.3 | 18 | 26 | 94 | 98 | 5 | 2 | 19 | 8 | M16 |

| 80 | 200 | 160 | 132 | 90 | 89.1 | 20 | 28 | 108 | 112 | 6 | 2 | 23 | 8 | M20 |

| -90 | 210 | 170 | 145 | 102.6 | 101.6 | 20 | 30 | 120 | 124 | 6 | 2 | 23 | 8 | M20 |

| 100 | 225 | 185 | 160 | 115.4 | 114.3 | 22 | 34 | 134 | 138 | 6 | 2 | 23 | 8 | M20 |

| 125 | 270 | 225 | 195 | 141.2 | 139.8 | 22 | 34 | 164 | 170 | 6 | 2 | 25 | 8 | M22 |

| 150 | 305 | 260 | 230 | 166.6 | 165.2 | 24 | 38 | 196 | 202 | 6 | 2 | 25 | 12 | M22 |

| 200 | 350 | 305 | 275 | 218 | 216.3 | 26 | 40 | 244 | 252 | 6 | 2 | 25 | 12 | M22 |

| 250 | 430 | 380 | 345 | 269.5 | 267.4 | 28 | 44 | 304 | 312 | 6 | 2 | 27 | 12 | M24 |

| 300 | 480 | 430 | 395 | 321 | 318.5 | 30 | 48 | 354 | 364 | 8 | 3 | 27 | 16 | M24 |

| 350 | 540 | 480 | 440 | 358.1 | 355.6 | 34 | 52 | 398 | 408 | 8 | 3 | 33 | 16 | M30X3 |

| 400 | 605 | 540 | 495 | 409 | 406.4 | 38 | 60 | 446 | 456 | 10 | 3 | 33 | 16 | M30X3 |

| 450 | 675 | 605 | 560 | 460 | 457.2 | 40 | 64 | 504 | 514 | 10 | 3 | 33 | 20 | M30X3 |

| 500 | 730 | 660 | 615 | 511 | 508 | 42 | 68 | 558 | 568 | 10 | 3 | 33 | 20 | M30X3 |

| -550 | 795 | 720 | 670 | 562 | 558.8 | 44 | 70 | 612 | 622 | 10 | 3 | 39 | 20 | M36X3 |

| 600 | 845 | 770 | 720 | 613 | 609.6 | 46 | 74 | 666 | 676 | 10 | 3 | 39 | 24 | M36X3 |

| -650 | 895 | 820 | 770 | 664 | 660.4 | 48 | 77 | 704 | 726 | 10 | 5 | 39 | 24 | M36X3 |

| 700 | 960 | 875 | 820 | 715 | 711.2 | 50 | 80 | 754 | 776 | 10 | 5 | 42 | 24 | M39X3 |

| -750 | 1020 | 935 | 880 | 766 | 762 | 52 | 83 | 806 | 832 | 10 | 5 | 42 | 24 | M39X3 |

| 800 | 1085 | 990 | 930 | 817 | 812.8 | 54 | 86 | 865 | 885 | 10 | 5 | 48 | 24 | M45X3 |

| -850 | 1135 | 1040 | 980 | 868 | 863.6 | 56 | 89 | 916 | 936 | 10 | 5 | 48 | 24 | M45X3 |

| 900 | 1185 | 1090 | 1030 | 919 | 914.4 | 58 | 93 | 968 | 986 | 10 | 5 | 48 | 28 | M45X3 |

| 1000 | 1320 | 1210 | 1140 | 1021 | 1016 | 62 | 99 | 1070 | 1098 | 12 | 5 | 56 | 28 | M52X3 |

| -1100 | 1420 | 1310 | 1240 | 1123 | 1117.6 | 66 | 105 | 1180 | 1200 | 12 | 5 | 56 | 32 | M52X3 |

| 1200 | 1530 | 1420 | 1350 | 1225 | 1219.2 | 70 | 112 | 1282 | 1302 | 12 | 5 | 56 | 32 | M52X3 |

| Nominal Dia. of Flange | Outside Dia. of Flange D | Sectional Dimensions of flange | Reference | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. of Bolt Circle C | Dia. Of raised Face g | Inside Dia. Of Flange do | Outside Dia. of Steel pipe | t | T | Dia. of Hub | Radius r | f | D | Number of Bolt Holes | Holes Dia. H | Nominal Bolt SIZE | S1 | M | S2 | N | L | |||

| a | b | |||||||||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 14 | 20 | 30 | 32 | 4 | 1 | – | 4 | 15 | M12 | 27 | 4 | 27 | 4 | – |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 14 | 20 | 34 | 36 | 4 | 1 | – | 4 | 15 | M12 | 31 | 4 | 31 | 4 | – |

| 20 | 100 | 75 | 56 | 27.7 | 27.2 | 16 | 22 | 40 | 42 | 4 | 1 | – | 4 | 15 | M12 | 37 | 4 | 37 | 4 | – |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 16 | 24 | 48 | 50 | 4 | 1 | 4 | 19 | M16 | 44 | 4 | 44 | 4.5 | – | |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 18 | 26 | 56 | 60 | 5 | 2 | – | 4 | 19 | M16 | 52 | 4 | 53 | 5 | – |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 18 | 26 | 62 | 66 | 5 | 2 | – | 4 | 19 | M16 | 58 | 4 | 59 | 5.5 | – |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 18 | 26 | 76 | 80 | 5 | 2 | – | 8 | 19 | M16 | 70 | 4 | 72 | 5.5 | – |

| 65 | 175 | 140 | 116 | 77.7 | 76.3 | 20 | 30 | 100 | 104 | 5 | 2 | 65.9 | 8 | 19 | M16 | 94 | 6 | – | – | 6 |

| 80 | 200 | 160 | 132 | 90 | 89.1 | 22 | 34 | 113 | 117 | 6 | 2 | 78.1 | 8 | 23 | M20 | 107 | 6 | – | – | 6 |

| -90 | 210 | 170 | 145 | 102.6 | 101.6 | 24 | 36 | 126 | 130 | 6 | 2 | 90.2 | 8 | 23 | M20 | 120 | 6 | – | – | 6 |

| 100 | 225 | 185 | 160 | 115.4 | 114.3 | 24 | 36 | 138 | 142 | 6 | 2 | 102.3 | 8 | 23 | M20 | 132 | 6 | – | – | 6 |

| 125 | 270 | 225 | 195 | 141.2 | 139.8 | 26 | 40 | 166 | 172 | 6 | 2 | 126.6 | 8 | 25 | M22 | 160 | 7 | – | – | 6 |

| 150 | 305 | 260 | 230 | 166.6 | 165.2 | 28 | 42 | 196 | 202 | 6 | 2 | 151 | 12 | 25 | M22 | 186 | 8 | – | – | 6 |

| 200 | 350 | 305 | 275 | 218 | 216.3 | 30 | 46 | 244 | 252 | 6 | 2 | 199.9 | 12 | 25 | M22 | 237 | 9 | – | – | 6 |

| 250 | 430 | 380 | 345 | 269.5 | 267.4 | 34 | 52 | 304 | 312 | 6 | 2 | 248.8 | 12 | 27 | M24 | 290 | 10 | – | – | 6 |

| 300 | 480 | 430 | 395 | 321 | 318.5 | 36 | 56 | 354 | 364 | 8 | 3 | 297.9 | 16 | 27 | M24 | 345 | 11 | – | – | 6 |

| 350 | 540 | 480 | 440 | 358.1 | 355.6 | 40 | 62 | 398 | 408 | 8 | 3 | 333.4 | 16 | 33 | M30X3 | 384 | 12 | – | – | 6 |

| 400 | 605 | 540 | 495 | 409 | 406.4 | 46 | 70 | 446 | 456 | 10 | 3 | 381 | 16 | 33 | M30X3 | 437 | 13 | – | – | 7 |

| 450 | 675 | 605 | 560 | 460 | 457.2 | 48 | 78 | 504 | 514 | 10 | 3 | 431.8 | 20 | 33 | M30X3 | 490 | 15 | – | – | 7 |

| 500 | 730 | 660 | 615 | 511 | 508 | 50 | 84 | 558 | 568 | 10 | 3 | 482.6 | 20 | 33 | M30X3 | 544 | 16 | – | – | 7 |

| -550 | 795 | 720 | 670 | 562 | 558.8 | 52 | 90 | 612 | 622 | 10 | 3 | 533.4 | 20 | 39 | M36X3 | 595 | 16 | – | – | 7 |

| 600 | 845 | 770 | 720 | 613 | 609.6 | 54 | 96 | 666 | 676 | 10 | 3 | 584.2 | 24 | 39 | M36X3 | 646 | 18 | – | – | 7 |

| *650 | 945 | 850 | 790 | 664 | 660.4 | 60 | 5 | 24 | 48 | M45X3 | ||||||||||

| *700 | 995 | 900 | 840 | 715 | 711.2 | 64 | 5 | 24 | 48 | M45X3 | ||||||||||

| *750 | 1080 | 970 | 900 | 766 | 762 | 68 | 5 | 24 | 56 | M52X3 | ||||||||||

| *800 | 1140 | 1030 | 960 | 817 | 812.8 | 72 | 5 | 24 | 56 | M52X3 | ||||||||||

| *850 | 1200 | 1090 | 1020 | 868 | 863.6 | 74 | 5 | 24 | 56 | M52X3 | ||||||||||

| *900 | 1250 | 1140 | 1070 | 919 | 914.4 | 76 | 5 | 28 | 56 | M52X3 | ||||||||||

| Nominal Dia. of Flange | Outside Dia. of Flange D | Sectional Dimensions of flange | Reference | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. of Bolt Circle C | Dia. Of raised Face g | Inside Dia. Of Flange do | Outside Dia. of Steel pipe | t | T | Dia. of Hub | Radius r | f | D | Number of Bolt Holes | Holes Dia. H | Nominal Bolt SIZE | S1 | M | S2 | N | L | |||

| a | b | |||||||||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 14 | 20 | 30 | 32 | 4 | 1 | – | 4 | 15 | M12 | 27 | 4 | 27 | 4 | – |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 14 | 20 | 34 | 36 | 4 | 1 | – | 4 | 15 | M12 | 31 | 4 | 31 | 4 | – |

| 20 | 100 | 75 | 56 | 27.7 | 27.2 | 16 | 22 | 40 | 42 | 4 | 1 | – | 4 | 15 | M12 | 37 | 4 | 37 | 4 | – |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 16 | 24 | 48 | 50 | 4 | 1 | 4 | 19 | M16 | 44 | 4 | 44 | 4.5 | – | |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 18 | 26 | 56 | 60 | 5 | 2 | – | 4 | 19 | M16 | 52 | 4 | 53 | 5 | – |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 18 | 26 | 62 | 66 | 5 | 2 | – | 4 | 19 | M16 | 58 | 4 | 59 | 5.5 | – |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 18 | 26 | 76 | 80 | 5 | 2 | – | 8 | 19 | M16 | 70 | 4 | 72 | 5.5 | – |

| 65 | 175 | 140 | 116 | 77.7 | 76.3 | 20 | 30 | 100 | 104 | 5 | 2 | 65.9 | 8 | 19 | M16 | 94 | 6 | – | – | 6 |

| 80 | 200 | 160 | 132 | 90 | 89.1 | 22 | 34 | 113 | 117 | 6 | 2 | 78.1 | 8 | 23 | M20 | 107 | 6 | – | – | 6 |

| -90 | 210 | 170 | 145 | 102.6 | 101.6 | 24 | 36 | 126 | 130 | 6 | 2 | 90.2 | 8 | 23 | M20 | 120 | 6 | – | – | 6 |

| 100 | 225 | 185 | 160 | 115.4 | 114.3 | 24 | 36 | 138 | 142 | 6 | 2 | 102.3 | 8 | 23 | M20 | 132 | 6 | – | – | 6 |

| 125 | 270 | 225 | 195 | 141.2 | 139.8 | 26 | 40 | 166 | 172 | 6 | 2 | 126.6 | 8 | 25 | M22 | 160 | 7 | – | – | 6 |

| 150 | 305 | 260 | 230 | 166.6 | 165.2 | 28 | 42 | 196 | 202 | 6 | 2 | 151 | 12 | 25 | M22 | 186 | 8 | – | – | 6 |

| 200 | 350 | 305 | 275 | 218 | 216.3 | 30 | 46 | 244 | 252 | 6 | 2 | 199.9 | 12 | 25 | M22 | 237 | 9 | – | – | 6 |

| 250 | 430 | 380 | 345 | 269.5 | 267.4 | 34 | 52 | 304 | 312 | 6 | 2 | 248.8 | 12 | 27 | M24 | 290 | 10 | – | – | 6 |

| 300 | 480 | 430 | 395 | 321 | 318.5 | 36 | 56 | 354 | 364 | 8 | 3 | 297.9 | 16 | 27 | M24 | 345 | 11 | – | – | 6 |

| 350 | 540 | 480 | 440 | 358.1 | 355.6 | 40 | 62 | 398 | 408 | 8 | 3 | 333.4 | 16 | 33 | M30X3 | 384 | 12 | – | – | 6 |

| 400 | 605 | 540 | 495 | 409 | 406.4 | 46 | 70 | 446 | 456 | 10 | 3 | 381 | 16 | 33 | M30X3 | 437 | 13 | – | – | 7 |

| 450 | 675 | 605 | 560 | 460 | 457.2 | 48 | 78 | 504 | 514 | 10 | 3 | 431.8 | 20 | 33 | M30X3 | 490 | 15 | – | – | 7 |

| 500 | 730 | 660 | 615 | 511 | 508 | 50 | 84 | 558 | 568 | 10 | 3 | 482.6 | 20 | 33 | M30X3 | 544 | 16 | – | – | 7 |

| -550 | 795 | 720 | 670 | 562 | 558.8 | 52 | 90 | 612 | 622 | 10 | 3 | 533.4 | 20 | 39 | M36X3 | 595 | 16 | – | – | 7 |

| 600 | 845 | 770 | 720 | 613 | 609.6 | 54 | 96 | 666 | 676 | 10 | 3 | 584.2 | 24 | 39 | M36X3 | 646 | 18 | – | – | 7 |

| *650 | 945 | 850 | 790 | 664 | 660.4 | 60 | 5 | 24 | 48 | M45X3 | ||||||||||

| *700 | 995 | 900 | 840 | 715 | 711.2 | 64 | 5 | 24 | 48 | M45X3 | ||||||||||

| *750 | 1080 | 970 | 900 | 766 | 762 | 68 | 5 | 24 | 56 | M52X3 | ||||||||||

| *800 | 1140 | 1030 | 960 | 817 | 812.8 | 72 | 5 | 24 | 56 | M52X3 | ||||||||||

| *850 | 1200 | 1090 | 1020 | 868 | 863.6 | 74 | 5 | 24 | 56 | M52X3 | ||||||||||

| *900 | 1250 | 1140 | 1070 | 919 | 914.4 | 76 | 5 | 28 | 56 | M52X3 | ||||||||||

| Nominal Pipe Size | Outside Dia. of Flange D | Sectional Dimensions of Flange | Nominal Bolt Size | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt Circle Dia. C | Dia. of Raised Face g | Outside Dia. of Steel Pipe | T | b | a | R | t | d | Radius r | s | f | Number of Bolt Holes | Dia. of Hole h | |||

| 15 | 115 | 80 | 55 | 21.7 | 45 | 40 | 22 | 20 | 18 | 15.8 | 6 | 3.1 | 1 | 4 | 19 | M16 |

| 20 | 120 | 85 | 60 | 27.2 | 45 | 44 | 27.5 | 20 | 18 | 21.1 | 6 | 3.2 | 1 | 4 | 19 | M16 |

| 25 | 130 | 95 | 70 | 34 | 48 | 52 | 34.4 | 20 | 20 | 26.8 | 6 | 3.8 | 1 | 4 | 19 | M16 |

| 32 | 140 | 105 | 80 | 42.7 | 52 | 62 | 43.1 | 30 | 22 | 35.1 | 6 | 4 | 2 | 4 | 19 | M16 |

| 40 | 160 | 120 | 90 | 48.6 | 54 | 70 | 49.1 | 30 | 22 | 40.7 | 6 | 4.2 | 2 | 4 | 23 | M20 |

| 50 | 165 | 130 | 105 | 60.5 | 57 | 84 | 61 | 30 | 22 | 52.2 | 8 | 4.4 | 2 | 8 | 19 | M16 |

| 65 | 200 | 160 | 130 | 76.3 | 69 | 105 | 76.9 | 30 | 26 | 65.3 | 8 | 5.8 | 2 | 8 | 23 | M20 |

| 80 | 210 | 170 | 140 | 89.1 | 73 | 118 | 89.7 | 30 | 28 | 76.4 | 8 | 6.1 | 2 | 8 | 23 | M20 |

| 90 | 230 | 185 | 150 | 101.6 | 74 | 130 | 102 | 30 | 30 | 89.5 | 8 | 6.4 | 2 | 8 | 25 | M22 |

| 100 | 240 | 195 | 160 | 114.3 | 76 | 142 | 115 | 30 | 32 | 101.5 | 8 | 6.8 | 2 | 8 | 25 | M22 |

| 125 | 275 | 230 | 195 | 139.8 | 86 | 172 | 141 | 50 | 36 | 125.7 | 10 | 7.5 | 2 | 8 | 25 | M22 |

| 150 | 325 | 275 | 235 | 165.2 | 95 | 202 | 166 | 50 | 38 | 150 | 10 | 8.1 | 2 | 12 | 27 | M24 |

| 200 | 370 | 320 | 280 | 216.3 | 102 | 254 | 218 | 50 | 42 | 198.7 | 10 | 9.4 | 2 | 12 | 27 | M24 |

| 250 | 450 | 390 | 345 | 267.4 | 118 | 312 | 269 | 50 | 48 | 247.5 | 12 | 10.6 | 2 | 12 | 33 | M30 3 |

| 300 | 515 | 450 | 405 | 318.5 | 127 | 366 | 320 | 50 | 52 | 296.4 | 15 | 11.8 | 3 | 16 | 33 | M30 3 |

| 350 | 560 | 495 | 450 | 355.6 | 134 | 406 | 357 | 80 | 54 | 331.8 | 15 | 12.7 | 3 | 16 | 33 | M30 3 |

| 400 | 630 | 560 | 510 | 406.4 | 149 | 462 | 408 | 80 | 60 | 379.1 | 20 | 14.6 | 3 | 16 | 39 | |

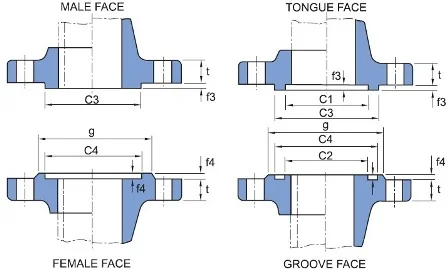

| Nominal Dia of Flange | Male & Female Type | Tongue & Groove Type | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C3 | C4 | f3 | f4 | C1 | C2 | C3 | C4 | f3 | f4 | |

| 10 | 38 | 39 | 6 | 5 | 28 | 27 | 38 | 39 | 6 | 5 |

| 15 | 42 | 43 | 6 | 5 | 32 | 31 | 42 | 43 | 6 | 5 |

| 20 | 50 | 51 | 6 | 5 | 38 | 37 | 50 | 51 | 6 | 5 |

| 25 | 60 | 61 | 6 | 5 | 45 | 44 | 60 | 61 | 6 | 5 |

| 32 | 70 | 71 | 6 | 5 | 55 | 54 | 70 | 71 | 6 | 5 |

| 40 | 75 | 76 | 6 | 5 | 60 | 59 | 75 | 76 | 6 | 5 |

| 50 | 90 | 91 | 6 | 5 | 70 | 69 | 90 | 91 | 6 | 5 |

| 65 | 110 | 111 | 6 | 5 | 90 | 89 | 110 | 111 | 6 | 5 |

| 80 | 120 | 121 | 6 | 5 | 100 | 99 | 120 | 121 | 6 | 5 |

| 90 | 130 | 131 | 6 | 5 | 110 | 109 | 130 | 131 | 6 | 5 |

| 100 | 145 | 146 | 6 | 5 | 125 | 124 | 145 | 146 | 6 | 5 |

| 125 | 175 | 176 | 6 | 5 | 150 | 149 | 175 | 176 | 6 | 5 |

| 150 | 215 | 216 | 6 | 5 | 190 | 189 | 215 | 216 | 6 | 5 |

| 20 | 260 | 261 | 6 | 5 | 230 | 229 | 260 | 261 | 6 | 5 |

| 250 | 325 | 326 | 6 | 5 | 295 | 294 | 325 | 326 | 6 | 5 |

| 300 | 375 | 376 | 6 | 5 | 340 | 339 | 375 | 376 | 6 | 5 |

| 350 | 415 | 416 | 6 | 5 | 380 | 379 | 415 | 416 | 6 | 5 |

| 400 | 475 | 476 | 6 | 5 | 440 | 439 | 475 | 476 | 6 | 5 |

| Nominal Dia of Flange | Male & Female Type | Tongue & Groove Type | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C3 | C4 | f3 | f4 | C1 | C2 | C3 | C4 | f3 | f4 | |

| 10 | 38 | 39 | 6 | 5 | 28 | 27 | 38 | 39 | 6 | 5 |

| 15 | 42 | 43 | 6 | 5 | 32 | 31 | 42 | 43 | 6 | 5 |

| 20 | 50 | 51 | 6 | 5 | 38 | 37 | 50 | 51 | 6 | 5 |

| 25 | 60 | 61 | 6 | 5 | 45 | 44 | 60 | 61 | 6 | 5 |

| 32 | 70 | 71 | 6 | 5 | 55 | 54 | 70 | 71 | 6 | 5 |

| 40 | 75 | 76 | 6 | 5 | 60 | 59 | 75 | 76 | 6 | 5 |

| 50 | 90 | 91 | 6 | 5 | 70 | 69 | 90 | 91 | 6 | 5 |

| 65 | 110 | 111 | 6 | 5 | 90 | 89 | 110 | 111 | 6 | 5 |

| 80 | 120 | 121 | 6 | 5 | 100 | 99 | 120 | 121 | 6 | 5 |

| 90 | 130 | 131 | 6 | 5 | 110 | 109 | 130 | 131 | 6 | 5 |

| 100 | 145 | 146 | 6 | 5 | 125 | 124 | 145 | 146 | 6 | 5 |

| 125 | 175 | 176 | 6 | 5 | 150 | 149 | 175 | 176 | 6 | 5 |

| 150 | 215 | 216 | 6 | 5 | 190 | 189 | 215 | 216 | 6 | 5 |

| 20 | 260 | 261 | 6 | 5 | 230 | 229 | 260 | 261 | 6 | 5 |

| 250 | 325 | 326 | 6 | 5 | 295 | 294 | 325 | 326 | 6 | 5 |

| 300 | 375 | 376 | 6 | 5 | 340 | 339 | 375 | 376 | 6 | 5 |

| 350 | 415 | 416 | 6 | 5 | 380 | 379 | 415 | 416 | 6 | 5 |

| 400 | 475 | 476 | 6 | 5 | 440 | 439 | 475 | 476 | 6 | 5 |

JIS B2220 standard flanges

The JIS B2220 standard specifies the dimensions, materials, pressure classes, and performance requirements for flanges used in piping systems based on Japanese Industrial Standards. These flanges are widely employed in industrial applications, particularly in systems adhering to Japanese or Asian specifications.

- ASME/ANSI Standards (American):

- ASME B16.5 – Pipe Flanges and Flanged Fittings (NPS 1/2" to 24").

- ASME B16.47 – Large Diameter Steel Flanges (Series A & B, NPS 26" to 60").

- ASME B16.36 – Orifice Flanges.

- ASME B16.48 – Line Blanks (Spectacle, Spade, and Spacer Flanges).

- ANSI B16.1 – Cast Iron Flanges and Flanged Fittings.

- ANSI B16.42 – Ductile Iron Pipe Flanges and Flanged Fittings.

- ISO Standards (International)

- ISO 7005-1 – Steel Flanges for General Applications.

- ISO 7005-2 – Cast Iron Flanges.

- ISO 7005-3 – Copper Alloy Flanges.

- EN Standards (European)

- EN 1092-1 – Steel Flanges.

- EN 1092-2 – Cast Iron Flanges.

- EN 1092-3 – Copper Alloy Flanges.

- EN 1092-4 – Aluminium Alloy Flanges.

- DIN Standards (German)

- DIN 2527 – Blind Flanges.

- DIN 2576 – Slip-On Flanges (PN 10).

- DIN 2633 – Weld Neck Flanges (PN 16).

- DIN 2634 – Weld Neck Flanges (PN 25).

- DIN 2635 – Weld Neck Flanges (PN 40).

- JIS Standards (Japanese)

- JIS B2220 – Steel Pipe Flanges.

- GOST Standards (Russian)

- GOST 12820 – Flat Flanges for Steel Pipe Joints.

- GOST 12821 – Steel Welded Flanges for High-Pressure Applications.

- GOST 33259 – Flange Connections for Industrial Equipment and Pipelines.

- BS Standards (British)

- BS 4504 – Circular Flanges for Pipes, Valves, and Fittings.

- BS 10 – Specification for Flanges and Bolting.

- API Standards (Oil & Gas)

- API 6A – Wellhead and Christmas Tree Equipment Flanges.

- API 605 – Large-Diameter Carbon Steel Flanges (merged into ASME B16.47 Series B).

- AWWA Standards (Waterworks)

- AWWA C207 – Steel Ring Flanges for Waterworks Service.

- MSS Standards (Manufacturer's Standardization Society)

- MSS SP-44 – Steel Pipe Flanges (merged into ASME B16.47 Series A).

- MSS SP-51 – Flanges for Glass-Lined Equipment.

- Material-Specific Standards (ASTM)

- ASTM A105 – Carbon Steel Forged Flanges.

- ASTM A182 – Alloy and Stainless Steel Forged Flanges.

- ASTM A350 – Carbon and Low-Alloy Steel Flanges for Low-Temperature Service.

- ASTM A694 – High-Strength Carbon and Alloy Steel Flanges for High-Pressure Applications.

- Other Regional and Specialized Standards

- KS B1511 – Korean Standard Flanges.

- NF E29-206 – French Standard Flanges.

- SANS 1123 – South African Standard for Steel Flanges.

Why Ample Alloys For JIS B2220 PN10 flange!

Ample Alloys stands out as a trusted supplier and manufacturer for JIS B2220 flanges, offering exceptional quality, precise manufacturing, and excellent customer service.

Commitment to Quality

Adherence to JIS B2220 specifications, ensuring durable, reliable flanges for demanding applications.

Precision Engineering

Advanced manufacturing techniques for perfect alignment, sealing, and performance.

Global Compliance

Conforms to international standards like ASME B16.5, DIN, and ISO for cross-compliance across industries.

Customization Options

Custom sizes, pressure ratings, and flange face types tailored to specific requirements.

JIS B2220 flanges are available in a variety of materials, including carbon steel, stainless steel, alloy steel, and other specialized alloys, depending on the specific requirements of the application.

JIS B2220 flanges are available in multiple pressure ratings, commonly ranging from PN 10 to PN 40, to meet the demands of different operating conditions.

JIS B2220 flanges are similar to ASME and DIN standards, with equivalent pressure ratings and material specifications, making them suitable for international projects. However, slight differences may exist in dimensions and design.