ASME B16.47 Series A/B (MSS SP-44) Flanges

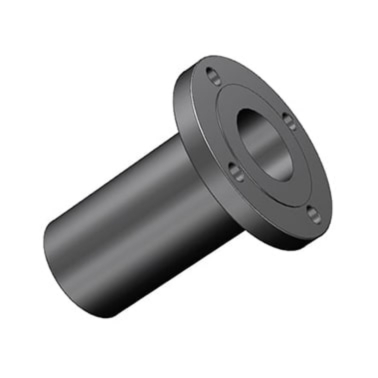

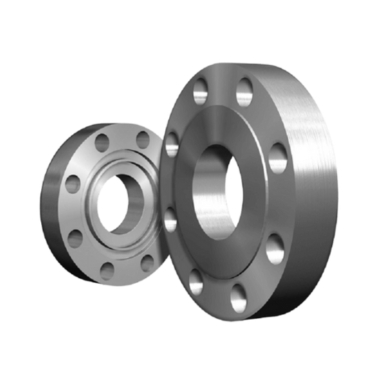

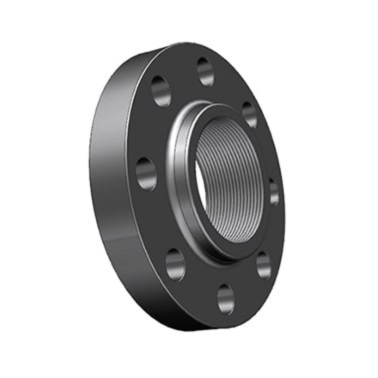

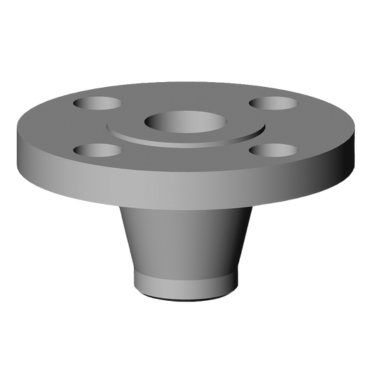

MSS SP 44 Flanges are high-quality, durable flanges manufactured to the specifications outlined by the Manufacturers Standardization Society (MSS). MSS SP 44 flanges are available in various types, including weld neck, slip-on, and blind flanges, and are commonly made from carbon steel to provide superior strength and corrosion resistance. With precise dimensions and robust construction, MSS SP 44 flanges ensure a secure and leak-proof connection in piping systems, making them a trusted choice for critical applications. These flanges comply with industry standards, offering both safety and reliability for demanding environments.

Ample Alloys is a leading manufacturer and supplier of high-quality MSS SP 44 flanges, offering a wide range of flange types, including weld neck, slip-on, and blind flanges. With years of experience in the industry, we specialize in providing durable and precision-engineered flanges that meet the rigorous standards of MSS SP 44, Ample Alloys delivers reliable and cost-effective MSS SP 44 flanges tailored to your specific requirements. With a focus on quality, customer satisfaction, and on-time delivery, we are your trusted partner for all flange needs.

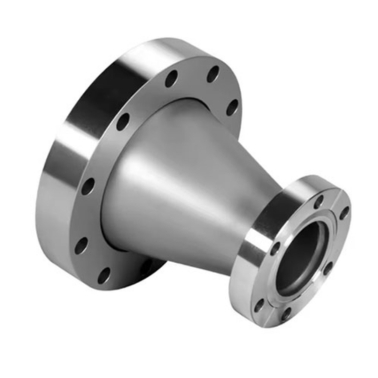

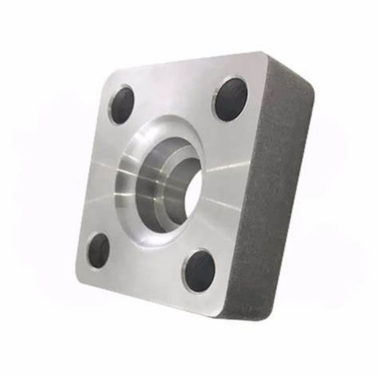

MSS SP-44 Class 150 Flat Faced Flange, MSS SP-44 Raised Face Flange, MSS SP 44 Weld Neck Flange, MSS SP 44 Slip-On Flange, High-Pressure MSS SP 44 Flanges, MSS SP 44 Carbon Steel Flanges, Durable MSS SP 44 Flanges

MSS SP-44 Pipe Flange Specifications

Size Range

15mm ( 1/2" NPS ) up to 1200 mm ( 48" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

MSS SP 44, ANSI/ASME B 16.47 Series A & B

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

Series A: Class 150, Class 300, Class 400, Class 600, and Class 900. Series B: Class 75, Class 150, and Class 300.

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

| Norminal Pipe Size | No.of Bolt Holes | O.D.of Flange, O | Raised Fase Diam., R | Min.Thick-ness of BL Flange, tf | Diam of Bolt Circle | Diam.of Bolt Hole | Approxi-mate Weight kgs |

|---|---|---|---|---|---|---|---|

| 26 | 24 | 870 | 749 | 66.7 | 806.4 | 34.9 | 306.37 |

| 28 | 28 | 925 | 800 | 69.9 | 863.6 | 34.9 | 362.18 |

| 30 | 28 | 985 | 857 | 73.1 | 914.2 | 34.9 | 431.26 |

| 32 | 28 | 1060 | 914 | 79.4 | 977.9 | 41.3 | 537.39 |

| 34 | 32 | 1110 | 965 | 81.0 | 1028.7 | 41.3 | 600.01 |

| 36 | 32 | 1170 | 1022 | 88.9 | 1085.8 | 41.3 | 733.85 |

| 38 | 32 | 1240 | 1073 | 85.8 | 1149.4 | 41.3 | 799.33 |

| 40 | 36 | 1290 | 1124 | 88.9 | 1200.2 | 41.3 | 894.73 |

| 42 | 36 | 1345 | 1194 | 95.3 | 1257.3 | 41.3 | 1045.24 |

| 44 | 40 | 1405 | 1245 | 100.1 | 1314.4 | 41.3 | 1196.23 |

| 46 | 40 | 1455 | 1295 | 101.6 | 1365.2 | 41.3 | 1305.08 |

| 48 | 44 | 1510 | 1359 | 106.4 | 1422.4 | 41.3 | 1470.44 |

| 50 | 44 | 1570 | 1410 | 109.6 | 1479.6 | 47.6 | 1623.89 |

| 52 | 44 | 1625 | 1461 | 114.3 | 1536.7 | 47.6 | 1818.21 |

| 54 | 44 | 1685 | 1511 | 119.1 | 1593.8 | 47.6 | 2041.23 |

| 56 | 48 | 1745 | 1575 | 122.3 | 1651.0 | 47.6 | 2246.21 |

| 58 | 48 | 1805 | 1626 | 127.0 | 1708.2 | 47.6 | 2500.27 |

| 60 | 52 | 1855 | 1676 | 130.2 | 1759.0 | 47.6 | 2704.21 |

| Norminal Pipe Size | No.of Bolt Holes | O.D.of Flange, O | Diam of Bolt Circle | Min.Thick-ness of BL Flange, tf | Raised Fase Diam., R | Diam.of Bolt Hole | Approxi-mate Weight kgs |

|---|---|---|---|---|---|---|---|

| 26 | 24 | 870 | 806.4 | 66.7 | 749 | 34.9 | 306.37 |

| 28 | 28 | 925 | 863.6 | 69.9 | 800 | 34.9 | 362.18 |

| 30 | 28 | 985 | 914.2 | 73.1 | 857 | 34.9 | 431.26 |

| 32 | 28 | 1060 | 977.9 | 79.4 | 914 | 41.3 | 537.39 |

| 34 | 32 | 1110 | 1028.7 | 81.0 | 965 | 41.3 | 600.01 |

| 36 | 32 | 1170 | 1085.8 | 88.9 | 1022 | 41.3 | 733.85 |

| 38 | 32 | 1240 | 1149.4 | 85.8 | 1073 | 41.3 | 799.33 |

| 40 | 36 | 1290 | 1200.2 | 88.9 | 1124 | 41.3 | 894.73 |

| 42 | 36 | 1345 | 1257.3 | 95.3 | 1194 | 41.3 | 1045.24 |

| 44 | 40 | 1405 | 1314.4 | 100.1 | 1245 | 41.3 | 1196.23 |

| 46 | 40 | 1455 | 1365.2 | 101.6 | 1295 | 41.3 | 1305.08 |

| 48 | 44 | 1510 | 1422.4 | 106.4 | 1359 | 41.3 | 1470.44 |

| 50 | 44 | 1570 | 1479.6 | 109.6 | 1410 | 47.6 | 1623.89 |

| 52 | 44 | 1625 | 1536.7 | 114.3 | 1461 | 47.6 | 1818.21 |

| 54 | 44 | 1685 | 1593.8 | 119.1 | 1511 | 47.6 | 2041.23 |

| 56 | 48 | 1745 | 1651.0 | 122.3 | 1575 | 47.6 | 2246.21 |

| 58 | 48 | 1805 | 1708.2 | 127.0 | 1626 | 47.6 | 2500.27 |

| 60 | 52 | 1855 | 1759.0 | 130.2 | 1676 | 47.6 | 2704.21 |

| Norminal Pipe Size | No.of Bolt Holes | O.D.of Flange, O | Diam of Bolt Circle | Min.Thick-ness of BL Flange, tf | Raised Fase Diam., R | Diam.of Bolt Hole | Approxi-mate Weight kgs |

|---|---|---|---|---|---|---|---|

| 26 | 28 | 890 | 806.4 | 111.3 | 727 | 44.5 | 528.79 |

| 28 | 28 | 950 | 863.6 | 115.9 | 784 | 47.6 | 626.51 |

| 30 | 28 | 1020 | 927.1 | 127.0 | 841 | 50.8 | 789.17 |

| 32 | 28 | 1085 | 984.2 | 134.9 | 895 | 54.0 | 946.54 |

| 34 | 24 | 1160 | 1054.1 | 144.2 | 953 | 60.3 | 1158.72 |

| 36 | 28 | 1215 | 1104.9 | 150.9 | 1010 | 60.3 | 1323.63 |

| Norminal Pipe Size | No.of Bolt Holes | O.D.of Flange, O | Diam of Bolt Circle | Min.Thick-ness of BL Flange, tf | Raised Fase Diam., R | Diam.of Bolt Hole | Approxi-mate Weight kgs |

|---|---|---|---|---|---|---|---|

| 26 | 20 | 1085 | 952.5 | 160.4 | 749 | 73.0 | 1083.74 |

| 28 | 20 | 1170 | 1022.4 | 171.5 | 800 | 79.4 | 1342.81 |

| 30 | 20 | 1230 | 1085.8 | 182.6 | 857 | 79.4 | 1594.25 |

| 32 | 20 | 1315 | 1155.7 | 193.7 | 914 | 85.7 | 1927.07 |

| 34 | 20 | 1395 | 1225.6 | 204.8 | 965 | 92.1 | 2284.99 |

| 36 | 20 | 1460 | 1289.0 | 214.4 | 1022 | 92.1 | 2640.60 |

| 38 | 20 | 1460 | 1289.0 | 215.9 | 1099 | 92.1 | 2665.81 |

| 40 | 24 | 1510 | 1339.8 | 223.9 | 1162 | 92.1 | 2927.11 |

| 42 | 24 | 1560 | 1390.6 | 231.8 | 1213 | 92.1 | 3253.10 |

| 44 | 24 | 1650 | 1463.7 | 242.9 | 1270 | 98.4 | 3801.41 |

| 46 | 24 | 1735 | 1536.7 | 255.6 | 1334 | 104.8 | 4408.64 |

| 48 | 24 | 1785 | 1587.5 | 263.6 | 1384 | 104.8 | 4836.34 |

| Pipe Normal Diam. | O.D. OF Flange |

Diam. of Bolt |

Thickness | Length Through Hub |

Diam. of Bolt Circle |

No. of Bolt Holes |

Diam. of Hub at Base |

Hub Diam. Top |

Raised Face Diam. |

Diam. of Bolt Holes |

Fillet Radius Min. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | O | DB | C | Y | BD | BN | X | A | R | BH | r1 |

| 26″ | 870 | 1 1/4 | 68.3 | 120.7 | 806.5 | 24 | 676.1 | 660.4 | 749.3 | 35.1 | 9.7 |

| 28″ | 927.1 | 1 1/4 | 71.4 | 125.5 | 863.6 | 28 | 726.9 | 711.2 | 800.1 | 35.1 | 11.2 |

| 30″ | 984.3 | 1 1/4 | 74.7 | 136.7 | 914.4 | 28 | 781.1 | 762 | 857.3 | 35.1 | 11.2 |

| 32″ | 1060.5 | 1 1/2 | 81 | 144.5 | 977.9 | 28 | 831.9 | 812.8 | 914.4 | 41.1 | 11.2 |

| 34″ | 1111.3 | 1 1/2 | 82.6 | 149.4 | 1028.7 | 32 | 882.7 | 863.6 | 965.2 | 41.1 | 12.7 |

| 36″ | 1168.4 | 1 1/2 | 90.4 | 157.2 | 1085.9 | 32 | 933.5 | 914.4 | 1022.4 | 41.1 | 12.7 |

| 38″ | 1238.3 | 1 1/2 | 87.4 | 157.2 | 1149.4 | 32 | 990.6 | 965.2 | 1073.2 | 41.1 | 12.7 |

| 40″ | 1289.1 | 1 1/2 | 90.4 | 163.6 | 1200.2 | 36 | 1041.4 | 1016 | 1124 | 41.1 | 12.7 |

| 42″ | 1346.2 | 1 1/2 | 96.8 | 171.5 | 1257.3 | 36 | 1092.2 | 1066.8 | 1193.8 | 41.1 | 12.7 |

| 44″ | 1403.4 | 1 1/2 | 101.6 | 177.8 | 1314.5 | 40 | 1143 | 1117.6 | 1244.6 | 41.1 | 12.7 |

| 46″ | 1454.2 | 1 1/2 | 103.1 | 185.7 | 1365.3 | 40 | 1196.8 | 1168.4 | 1295.4 | 41.1 | 12.7 |

| 48″ | 1511.3 | 1 1/2 | 108 | 192 | 1422.4 | 44 | 1247.6 | 1219.2 | 1358.9 | 41.1 | 12.7 |

| 50″ | 1568.5 | 1 3/4 | 111.3 | 203.2 | 1479.6 | 44 | 1301.8 | 1270 | 1409.7 | 47.8 | 12.7 |

| 52″ | 1625.6 | 1 3/4 | 115.8 | 209.6 | 1536.7 | 44 | 1352.6 | 1320.8 | 1460.5 | 47.8 | 12.7 |

| 54″ | 1682.8 | 1 3/4 | 120.7 | 215.9 | 1593.9 | 44 | 1403.4 | 1371.6 | 1511.3 | 47.8 | 12.7 |

| 56″ | 1746.3 | 1 3/4 | 124 | 228.6 | 1651 | 48 | 1457.5 | 1422.4 | 1574.8 | 47.8 | 12.7 |

| 58″ | 1803.4 | 1 3/4 | 128.5 | 235 | 1708.2 | 48 | 1508.3 | 1473.2 | 1625.6 | 47.8 | 12.7 |

| 60″ | 1854.2 | 1 3/4 | 131.8 | 239.8 | 1759 | 52 | 1559.1 | 1524 | 1676.4 | 47.8 | 12.7 |

MSS SP 44 Weld Neck Flange Standards

MSS SP 44 flanges are manufactured according to the standards set by the Manufacturers Standardization Society (MSS) for carbon steel flanges.

- ASME/ANSI Standards (American):

- ASME B16.47 – Large Diameter Steel Flanges (Series A & B, NPS 26" to 60").

- MSS Standards (Manufacturer's Standardization Society)

- MSS SP-44 – Steel Pipe Flanges (merged into ASME B16.47 Series A).

- MSS SP-51 – Flanges for Glass-Lined Equipment.

- Material-Specific Standards (ASTM)

- ASTM A105 – Carbon Steel Forged Flanges.

- ASTM A350 – Carbon and Low-Alloy Steel Flanges for Low-Temperature Service.

- ASTM A694 – High-Strength Carbon and Alloy Steel Flanges for High-Pressure Applications.

- Other Regional and Specialized Standards

- KS B1511 – Korean Standard Flanges.

- NF E29-206 – French Standard Flanges.

- SANS 1123 – South African Standard for Steel Flanges.

Why Ample Alloys For MSS SP 44 Flange !

Ample Alloys is a trusted supplier of high-quality MSS SP 44 flanges, offering:

Compliance with Industry Standards

Our flanges meet MSS SP 44 and ASME B16.47 Series A specifications.

Top-Quality Materials

Made from premium carbon steel for durability and corrosion resistance.

Expertise

Years of experience in manufacturing reliable, precision-engineered flanges.

Competitive Pricing

Affordable pricing without compromising on quality.

MSS SP 44 flanges are commonly made from carbon steel, providing strength, durability, and resistance to high-pressure conditions. Other materials such as stainless steel and alloy steel can also be used depending on the application requirements.

MSS SP 44 flanges are available in various types, including weld neck, slip-on, blind, and threaded flanges, to accommodate different piping configurations and installation requirements.

MSS SP 44 flanges are widely used in industries like oil & gas, petrochemical, power generation, and construction, where robust and leak-proof connections are critical.