ISO 7005-1, 7005-2, 2084, 6162-1 And 6162-2, 1609, 6182-1, 2531, 9001, 10838 Flange

ISO Flange Standards define the specifications for flanges used in industrial piping systems. The most common standard, ISO 7005-1, covers the general requirements for flanges, including dimensions, material specifications, pressure ratings, and types of flanges such as weld neck, slip-on, blind, and threaded. These standards ensure that flanges are compatible across different industries and provide reliable connections for piping systems in sectors like oil and gas, petrochemical, water treatment, and more. ISO flanges are designed for high performance, ensuring durability, corrosion resistance, and secure sealing under high pressure and temperature conditions. Compliance with ISO standards guarantees the quality, safety, and reliability of flanges in diverse applications.

Ample Alloys is a leading manufacturer and supplier of high-quality ISO Flanges products. With a commitment to excellence, we provide a wide range of products tailored to meet the needs of various industries. Our extensive product portfolio includes ISO 7005-1, 7005-2, 2084, 6162-1 And 6162-2, 1609, 6182-1, 2531, 9001, 10838 Flanges. At Ample Alloys, we pride ourselves on offering customized solutions, ensuring that our products meet strict industry standards and customer specifications. Our dedication to quality, reliability, and on-time delivery makes us a trusted partner for clients across the globe.

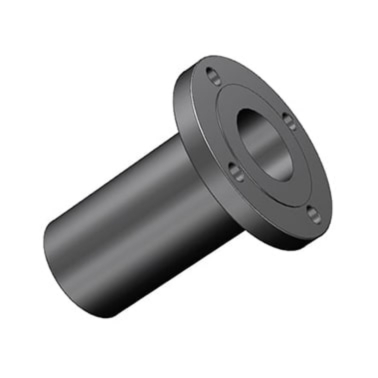

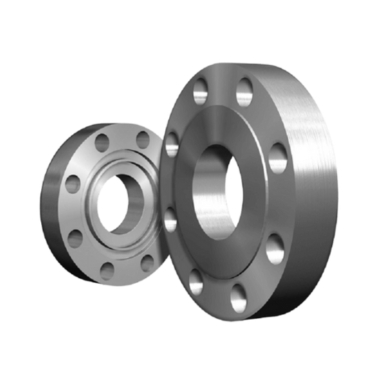

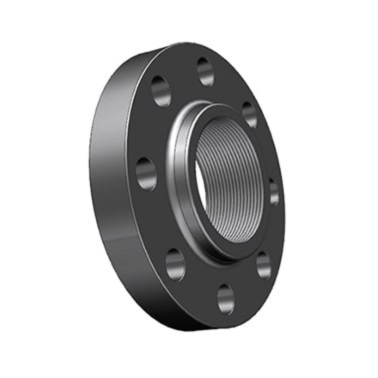

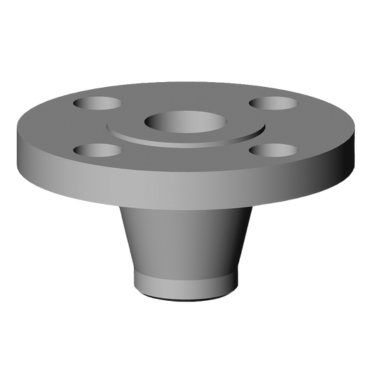

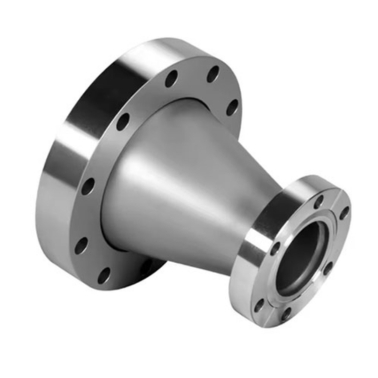

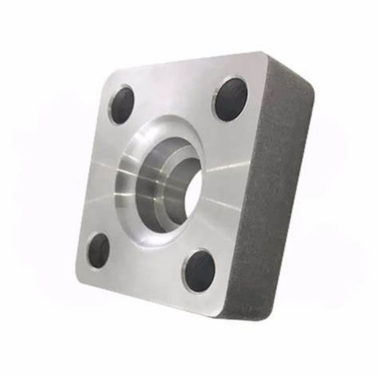

ISO-K Vacuum Flange, ISO HV Flange, ISO 7005-1 Compliant Flange, ISO-F Vacuum Flange, ISO 6162 Hydraulic Flange, ISO welding flanges, ISO blind flange, ISO slip-on flange, ISO weld neck flange, ISO socket weld flange, ISO stainless steel flange

ISO certified flanges Specifications

Size Range

ISO 7005-1 - DN 10 (NPS 3/8) to DN 4000 (NPS 160), ISO-K - NW10 (10 mm) to NW1000 (1000 mm), ISO-F - DN 10 (NPS 3/8) to DN 630 (NPS 24), ISO 6162 - DN 13.5 (NPS 1/2) to DN 101.6 (NPS 4)

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ISO 7005-1, ISO 7005-2, ISO 2084, ISO 6162-1 And 6162-2, ISO 1609, ISO 6182-1, ISO 2531

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

PN 6, PN 10, PN 16, PN 25, PN 35, PN 40, PN 50, PN 60, PN 63, PN 100, PN 160, PN 250, and PN 400. HV, UHV

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

ISO Flange - Dimensions

| Flange Size | Tube O.D. (in.) |

Flange O.D. in.(mm) |

Flange Thickness in.(mm) |

Number of Clamps | Assembly Diameter in.(mm) |

|

|---|---|---|---|---|---|---|

| Minimal | Optimal | |||||

| ISO 63 | 2.5 | 3.74 (95) | 0.47 (11.94) | 3 | 4 | 5.00 (127) |

| ISO 80 | 3 | 4.33 (110) | 0.47 (11.94) | 4 | 8 | 5.59 (142) |

| ISO 100 | 4 | 5.12 (130) | 0.47 (11.94) | 4 | 8 | 6.38 (162) |

| ISO 160 | 6 | 7.09 (180) | 0.47 (11.94) | 4 | 8 | 8.35 (212) |

| ISO 200 | 8 | 9.45 (240) | 0.47 (11.94) | 6 | 12 | 10.71 (272) |

| ISO 250 | 10 | 11.42 (290) | 0.47 (11.94) | 6 | 12 | 12.68 (322) |

| ISO 320 | 12.75 | 14.57 (370) | 0.67 (17.02) | 8 | 12 | 16.73 (425) |

| ISO 400 | 16 | 17.72 (450) | 0.67 (17.02) | 8 | 16 | 20.08 (510) |

| ISO 500 | 20 | 21.65 (550) | 0.67 (17.02) | 12 | 16 | 24.02 (610) |

| ISO 630 | 24 | 27.17 (690) | 0.87 (22.10) | 14 | 18 | 29.53 (750) |

| Flange Size | Tube O.D. (in.) |

Flange O.D. in.(mm) |

Flange Thickness in.(mm) |

No. of Bolts | Holes Diameter in.(mm) |

BCD in.(mm) |

|---|---|---|---|---|---|---|

| ISO 63 | 2.5 | 5.12 (130) | 0.47 (11.94) | 4 | 0.35 (9) | 4.33 (110) |

| ISO 80 | 3 | 5.71 (145) | 0.47 (11.94) | 8 | 0.35 (9) | 4.92 (125) |

| ISO 100 | 4 | 6.50 (165) | 0.47 (11.94) | 8 | 0.35 (9) | 5.71 (145) |

| ISO 160 | 6 | 8.86 (225) | 0.63 (16.00) | 8 | 0.43 (11) | 7.87 (200) |

| ISO 200 | 8 | 11.22 (285) | 0.63 (16.00) | 12 | 0.43 (11) | 10.24 (260) |

| ISO 250 | 10 | 13.19 (335) | 0.63 (16.00) | 12 | 0.43 (11) | 12.20 (310) |

| ISO 320 | 12.75 | 16.73 (425) | 0.79 (20.07) | 12 | 0.55 (14) | 15.55 (395) |

| ISO 400 | 16 | 20.08 (510) | 0.79 (20.07) | 16 | 0.55 (14) | 18.90 (480) |

| ISO 500 | 20 | 24.02 (610) | 0.79 (20.07) | 16 | 0.55 (14) | 22.83 (580) |

| ISO 630 | 24 | 29.53 (750) | 0.94 (23.88) | 20 | 0.55 (14) | 28.35 (720) |

| Size | Lip O.D. in.(mm) |

Lip I.D. in.(mm) |

Thickness in.(mm) |

|---|---|---|---|

| ISO 63 | 2.756 (70) | 2.63 (66.8) | 0.154 (3.9) |

| ISO 80 | 3.268 (83) | 3.14 (79.8) | 0.154 (3.9) |

| ISO 100 | 4.016 (102) | 3.89 (98.8) | 0.154 (3.9) |

| ISO 160 | 6.024(153) | 5.90 (149.9) | 0.154 (3.9) |

| ISO 200 | 8.386 (213) | 8.26 (209.8) | 0.154 (3.9) |

| ISO 250 | 10.276 (261) | 10.14 (257.6) | 0.154 (3.9) |

| ISO 320 | 12.520 (318) | 12.30 (312.4) | 0.220 (5.6) |

| ISO 400 | 15.748 (400) | 15.53 (394.5) | 0.220 (5.6) |

| ISO 500 | 19.724 (501) | 19.51 (495.6) | 0.220 (5.6) |

| ISO 630 | 25.630 (651) | 25.41 (645.4) | 0.220 (5.6) |

ISO pipe flanges Standards

ISO Pipe Flanges standards are internationally recognized specifications that define the design, dimensions, materials, and pressure ratings for flanges used in piping systems. These standards ensure consistency, safety, and interoperability across industries such as oil and gas, petrochemical, power generation, and water treatment.

-

ISO 7005-1: Steel flanges for use in pressure systems. It includes requirements for dimensions, materials, and pressure ratings for steel flanges such as weld neck, slip-on, blind, and threaded flanges, commonly used in high-pressure applications.

-

ISO 7005-2: Cast iron flanges for pressure systems. This standard provides requirements for cast iron flanges, typically used in lower-pressure applications, such as in water treatment systems.

-

ISO 7005-3: Stainless steel flanges. This standard applies to stainless steel flanges used in corrosive environments and specifies materials and dimensions for their use in pressure piping systems.

-

ISO 5752: Flanged pipe joints – dimensions of flanged pipe joints. This standard defines the dimensions and pressure ratings for flanged joints in industrial piping systems, ensuring reliable and leak-proof connections.

-

ISO 9001: Quality management systems. While not specific to flanges, ISO 9001 certifies the overall quality control systems of manufacturers, ensuring products, including flanges, meet stringent quality standards.

-

ISO 6162: Flanges for hydraulic systems. This standard specifies the design and dimensional requirements for flanges used in hydraulic systems, such as for oil and gas pipelines.

-

ISO 10838: Flanges for use in industrial piping systems. It outlines requirements for flanges designed for industrial systems, ensuring compatibility with various materials and pressure classes.

-

ISO 10423: Wellhead and Christmas tree equipment. While related to oil and gas, this standard specifies the design and materials for flanges used in wellhead equipment.

-

ISO 5208: Pressure testing of valves. Though not specifically for flanges, this standard outlines pressure testing procedures often associated with flanged valves and fittings.

-

ISO 1538: Flanged joints for pipelines. This standard provides guidelines for flanged joints used in the construction of pipelines, including the dimensions, material selection, and testing requirements.

-

ISO 28783: Industrial valves – Flanged joints for industrial valve applications. This standard specifically focuses on flanges used in valve applications, including pressure and temperature requirements.

Why Ample Alloys For ISO 7005-1 flanges!

Ample Alloys is a trusted provider for ISO flanges, offering a range of benefits that make us the go-to choice for industries requiring high-quality, reliable flanges. Here’s why you should choose Ample Alloys for your ISO flange needs:

Compliance with ISO Standards

We ensure that all our ISO flanges meet or exceed the specific requirements of the ISO 7005-1 standard, guaranteeing the right dimensions, materials, and pressure ratings for your applications.

Wide Selection of Flanges

Our range of ISO flanges includes various types such as weld neck, slip-on, blind, and threaded flanges, suitable for a wide variety of industrial piping systems.

Precision Manufacturing

Our state-of-the-art manufacturing techniques and stringent quality control processes ensure that each flange meets exacting standards, ensuring optimal performance in your systems.

Competitive Pricing

We offer ISO 7005-1 flanges at cost-effective prices without compromising on quality, giving you the best value for your investment.

- ISO 7005-1: Flanges for pipes, valves, fittings, and accessories.

- ISO 5752: Flanges and their pressure-temperature ratings.

- ISO 9001: Quality management systems applicable to flange manufacturers.

ISO flanges are generally compatible with other flange standards (like ASME or ANSI) when proper adapters or transitioning components are used. However, it's crucial to ensure dimensional compatibility for a secure connection.

ISO flanges are standardized by the International Organization for Standardization (ISO), while ANSI and ASME standards are American-based. The key differences may include dimensional variations, pressure ratings, and material specifications based on regional standards.