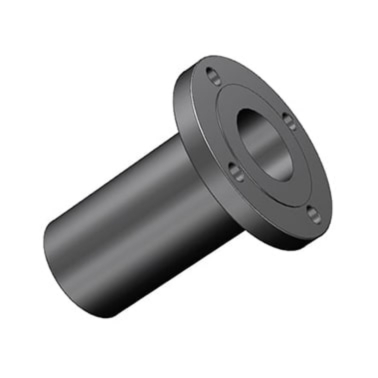

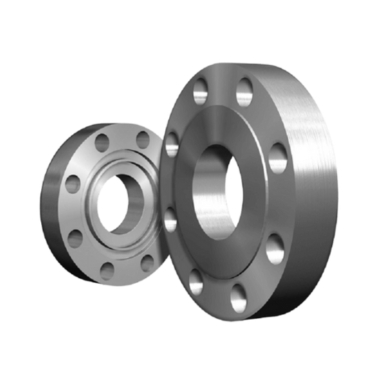

AS/NZS 4331.1 Flange, AS 4087 Flange, Australian Slip On Flange

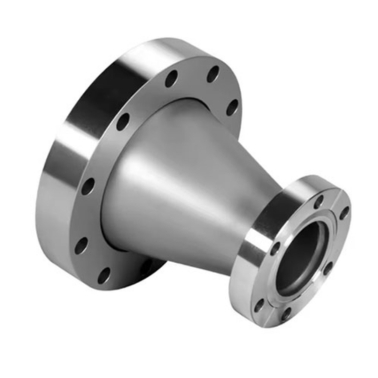

Australian Flange Standards are critical for ensuring the reliability and safety of flange-based connections in various industrial applications. Prominent Australian flange standards include AS 4087 for metallic flanges used in waterworks, AS 2129 for flanges in general piping systems, and AS 2862 for flanges in the petroleum and chemical industries. Additionally, These standards specify the materials, dimensions, design, and pressure ratings for different types of flanges, such as slip-on, weld neck, and blind flanges, ensuring compatibility with the required system pressures and temperatures. Compliance with Australian flange standards is essential for optimal performance, durability, and safety across various sectors.

Ample Alloys is a trusted manufacturer and supplier of high-quality Australian flanges, offering a wide range of products that meet rigorous industry standards. Our commitment to precision and quality ensures that every flange we produce adheres to the specific requirements outlined in Australian standards such as AS 4087, AS 2129, and AS 2862. Whether it's flanges for waterworks, petroleum, or chemical industries, We delivers products designed to withstand high pressure and extreme conditions. Our extensive experience, skilled engineering team, and top-notch materials ensure that you receive reliable, durable, and cost-effective flanges tailored to your project's unique needs. With Ample Alloys, you can trust that your Australian flange requirements will be met with unparalleled quality and timely delivery, backed by exceptional customer support.

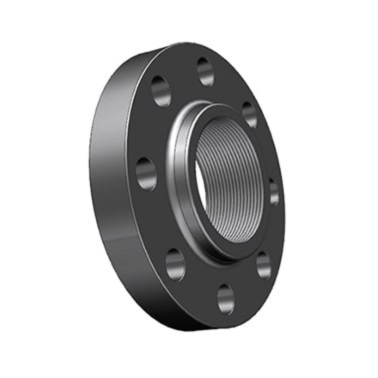

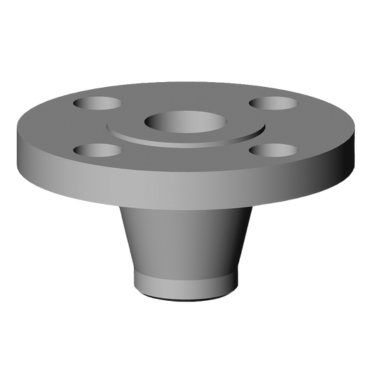

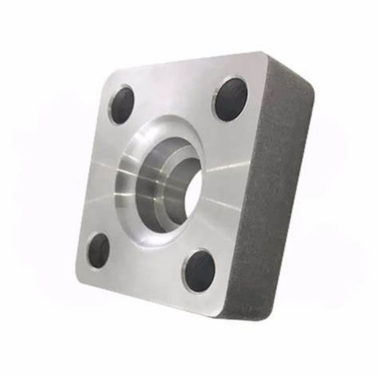

High-Quality Australian Flanges, Series A and B Australian Flanges, MSS SP-44 Australian Flanges, Class 150 Australian Flange, SS Australian Flanges, Australian Plate Flanges, Australian Blind Flanges, Australian Lapped joint Flanges, Australian Threaded Flange

Australian Steel Flanges Specifications

Size Range

15mm ( 1/2" NPS ) up to 1200 mm ( 48" NPS )

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

AS 4087, AS 2129, ASME B16.5, AS 2862, AS 4331

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 and Class 2500.

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

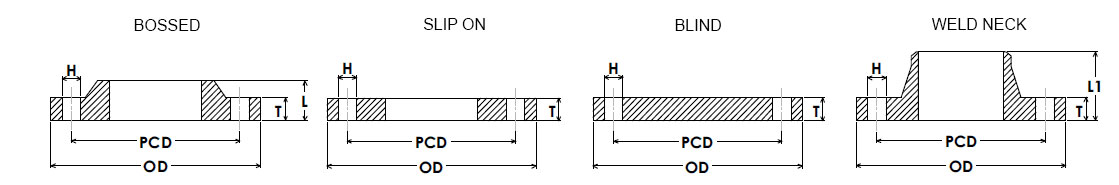

AS 2129 Flange - Dimensions

| TABLE D | LENGTH THROUGH HUB | DRILLING DATA | ||||||

| NOMINAL PIPE SIZE | FLANGE OUTSIDE DIAMETER | THICKNESS OF FLANGE (Refer Note.1) |

BOSSED SOW | WELD NECK | PITCH CIRCLE DIAMETER | BOLT HOLE DIAMETER | NUMBER OF BOLT HOLES |

|

| MM | INCH | OD | T | L | L1 | PCD | H | # |

| 15 | 1/2 | 95 | 5 | 15 | 27 | 67 | 14 | 4 |

| 20 | 3/4 | 100 | 5 | 16 | 27 | 73 | 14 | 4 |

| 25 | 1 | 115 | 5 | 16 | 27 | 83 | 14 | 4 |

| 32 | 1 1/4 | 120 | 6 | 17 | 31 | 87 | 14 | 4 |

| 40 | 1 1/2 | 135 | 6 | 19 | 35 | 98 | 14 | 4 |

| 50 | 2 | 150 | 8 | 21 | 37 | 114 | 18 | 4 |

| 65 | 2 1/2 | 165 | 8 | 24 | 40 | 127 | 18 | 4 |

| 80 | 3 | 185 | 10 | 26 | 45 | 146 | 18 | 4 |

| 90 | 3 1/2 | 205 | 10 | 27 | 45 | 165 | 18 | 4 |

| 100 | 4 | 215 | 10 | 29 | 51 | 178 | 18 | 4 |

| 125 | 5 | 255 | 13 | 32 | 57 | 210 | 18 | 8 |

| 150 | 6 | 280 | 13 | 32 | 61 | 235 | 18 | 8 |

| 200 | 8 | 335 | 13 | 35 | 64 | 292 | 18 | 8 |

| 250 | 10 | 405 | 16 | 43 | 80 | 356 | 22 | 8 |

| 300 | 12 | 455 | 19 | 48 | 89 | 406 | 22 | 12 |

| 350 | 14 | 525 | 22 | 95 | 470 | 26 | 12 | |

| 400 | 16 | 580 | 22 | 521 | 26 | 12 | ||

| 450 | 18 | 640 | 25 | 584 | 26 | 12 | ||

| 500 | 20 | 705 | 29 | 641 | 26 | 16 | ||

| 550 | 22 | 760 | 29 | 699 | 30 | 16 | ||

| 600 | 24 | 825 | 32 | 756 | 30 | 16 | ||

| 700 | 28 | 910 | 35 | 845 | 30 | 20 | ||

| 750 | 30 | 995 | 41 | 927 | 33 | 20 | ||

| 800 | 32 | 1060 | 41 | 984 | 36 | 20 | ||

| 850 | 34 | 1090 | 44 | 1016 | 36 | 20 | ||

| 900 | 36 | 1175 | 48 | 1092 | 36 | 24 | ||

| 1000 | 40 | 1255 | 51 | 1175 | 36 | 24 | ||

| 1050 | 42 | 1335 | 54 | 1251 | 36 | 28 | ||

| 1200 | 48 | 1490 | 60 | 1410 | 36 | 32 | ||

| TABLE E | LENGTH THROUGH HUB | DRILLING DATA | ||||||

| NOMINAL PIPE SIZE | FLANGE OUTSIDE DIAMETER | THICKNESS OF FLANGE (Refer Note.1) |

BOSSED SOW | WELD NECK | PITCH CIRCLE DIAMETER | BOLT HOLE DIAMETER | NUMBER OF BOLT HOLES | |

| MM | INCH | OD | T | L | L1 | PCD | H | # |

| 15 | 1/2 | 95 | 6 | 16 | 28 | 67 | 14 | 4 |

| 20 | 3/4 | 100 | 6 | 17 | 28 | 73 | 14 | 4 |

| 25 | 1 | 115 | 7 | 18 | 29 | 83 | 14 | 4 |

| 32 | 1 1/4 | 120 | 8 | 19 | 33 | 87 | 14 | 4 |

| 40 | 1 1/2 | 135 | 9 | 22 | 38 | 98 | 14 | 4 |

| 50 | 2 | 150 | 10 | 23 | 39 | 114 | 18 | 4 |

| 65 | 2 1/2 | 165 | 10 | 26 | 42 | 127 | 18 | 4 |

| 80 | 3 | 185 | 11 | 27 | 46 | 146 | 18 | 4 |

| 90 | 3 1/2 | 205 | 12 | 29 | 47 | 165 | 18 | 8 |

| 100 | 4 | 215 | 13 | 32 | 54 | 178 | 18 | 8 |

| 125 | 5 | 255 | 14 | 33 | 58 | 210 | 18 | 8 |

| 150 | 6 | 280 | 17 | 36 | 65 | 235 | 22 | 8 |

| 200 | 8 | 335 | 19 | 41 | 70 | 292 | 22 | 8 |

| 250 | 10 | 405 | 22 | 49 | 86 | 356 | 22 | 12 |

| 300 | 12 | 455 | 25 | 54 | 95 | 406 | 26 | 12 |

| 350 | 14 | 525 | 29 | 102 | 470 | 26 | 12 | |

| 400 | 16 | 580 | 32 | 521 | 26 | 12 | ||

| 450 | 18 | 640 | 35 | 584 | 26 | 16 | ||

| 500 | 20 | 705 | 38 | 641 | 26 | 16 | ||

| 550 | 22 | 760 | 44 | 699 | 30 | 16 | ||

| 600 | 24 | 825 | 48 | 756 | 33 | 16 | ||

| 700 | 28 | 910 | 51 | 845 | 33 | 20 | ||

| 750 | 30 | 995 | 54 | 927 | 36 | 20 | ||

| 800 | 32 | 1060 | 54 | 984 | 36 | 20 | ||

| 850 | 34 | 1090 | 57 | 1016 | 36 | 20 | ||

| 900 | 36 | 1175 | 64 | 1092 | 36 | 24 | ||

| 1000 | 40 | 1255 | 67 | 1175 | 39 | 24 | ||

| 1050 | 42 | 1335 | 70 | 1251 | 39 | 28 | ||

| 1200 | 48 | 1490 | 79 | 1410 | 39 | 32 | ||

| TABLE F | LENGTH THROUGH HUB | DRILLING DATA | ||||||

| NOMINAL PIPE SIZE | FLANGE OUTSIDE DIAMETER | THICKNESS OF FLANGE (Refer Note.1) |

BOSSED SOW | WELD NECK | PITCH CIRCLE DIAMETER | BOLT HOLE DIAMETER | NUMBER OF BOLT HOLES | |

| MM | INCH | OD | T | L | L1 | PCD | H | # |

| 15 | 1/2 | 95 | 10 | 20 | 32 | 67 | 14 | 4 |

| 20 | 3/4 | 100 | 10 | 21 | 32 | 73 | 14 | 4 |

| 25 | 1 | 120 | 10 | 21 | 39 | 87 | 18 | 4 |

| 32 | 1 1/4 | 135 | 13 | 24 | 48 | 98 | 18 | 4 |

| 40 | 1 1/2 | 140 | 13 | 26 | 48 | 105 | 18 | 4 |

| 50 | 2 | 165 | 16 | 29 | 51 | 127 | 18 | 4 |

| 65 | 2 1/2 | 185 | 16 | 32 | 54 | 146 | 18 | 8 |

| 80 | 3 | 205 | 16 | 32 | 60 | 165 | 18 | 8 |

| 90 | 3 1/2 | 215 | 19 | 36 | 63 | 178 | 18 | 8 |

| 100 | 4 | 230 | 19 | 38 | 70 | 191 | 18 | 8 |

| 125 | 5 | 280 | 22 | 41 | 79 | 235 | 22 | 8 |

| 150 | 6 | 305 | 22 | 41 | 79 | 260 | 22 | 12 |

| 200 | 8 | 370 | 25 | 47 | 92 | 324 | 22 | 12 |

| 250 | 10 | 430 | 29 | 56 | 102 | 381 | 26 | 12 |

| 300 | 12 | 490 | 32 | 61 | 111 | 438 | 26 | 16 |

| 350 | 14 | 550 | 35 | 495 | 30 | 16 | ||

| 400 | 16 | 610 | 41 | 552 | 30 | 20 | ||

| 450 | 18 | 675 | 44 | 610 | 33 | 20 | ||

| 500 | 20 | 735 | 51 | 673 | 33 | 24 | ||

| 550 | 22 | 785 | 54 | 724 | 33 | 24 | ||

| 600 | 24 | 850 | 57 | 781 | 36 | 24 | ||

| 700 | 28 | 935 | 60 | 857 | 36 | 24 | ||

| 750 | 30 | 1015 | 67 | 940 | 36 | 28 | ||

| 800 | 32 | 1060 | 68 | 984 | 36 | 28 | ||

| 850 | 34 | 1090 | 70 | 1016 | 36 | 32 | ||

| 900 | 36 | 1185 | 76 | 1105 | 39 | 32 | ||

| 1000 | 40 | 1275 | 83 | 1194 | 39 | 36 | ||

| 1050 | 42 | 1355 | 86 | 1270 | 39 | 36 | ||

| 1200 | 48 | 1530 | 95 | 1441 | 42 | 40 | ||

| TABLE H | LENGTH THROUGH HUB | DRILLING DATA | ||||||

| NOMINAL PIPE SIZE | FLANGE OUTSIDE DIAMETER | THICKNESS OF FLANGE |

BOSSED SOW | WELD NECK | PITCH CIRCLE DIAMETER | BOLT HOLE DIAMETER | NUMBER OF BOLT HOLES | |

| MM | INCH | OD | T | L | L1 | PCD | H | # |

| 15 | 1/2 | 115 | 13 | 23 | 42 | 83 | 18 | 4 |

| 20 | 3/4 | 115 | 13 | 24 | 42 | 83 | 18 | 4 |

| 25 | 1 | 120 | 14 | 25 | 43 | 87 | 18 | 4 |

| 32 | 1 1/4 | 135 | 17 | 28 | 52 | 98 | 18 | 4 |

| 40 | 1 1/2 | 140 | 17 | 30 | 52 | 105 | 18 | 4 |

| 50 | 2 | 165 | 19 | 32 | 54 | 127 | 18 | 4 |

| 65 | 2 1/2 | 185 | 19 | 35 | 57 | 146 | 18 | 8 |

| 80 | 3 | 205 | 22 | 38 | 66 | 165 | 18 | 8 |

| 90 | 3 1/2 | 215 | 22 | 39 | 66 | 178 | 18 | 8 |

| 100 | 4 | 230 | 25 | 44 | 76 | 191 | 18 | 8 |

| 125 | 5 | 280 | 29 | 48 | 86 | 235 | 22 | 8 |

| 150 | 6 | 305 | 29 | 48 | 86 | 260 | 22 | 12 |

| 200 | 8 | 370 | 32 | 54 | 99 | 324 | 22 | 12 |

| 250 | 10 | 430 | 35 | 62 | 108 | 381 | 26 | 12 |

| 300 | 12 | 490 | 41 | 70 | 120 | 438 | 26 | 16 |

| 350 | 14 | 550 | 48 | 495 | 30 | 16 | ||

| 400 | 16 | 610 | 54 | 552 | 30 | 20 | ||

| 450 | 18 | 675 | 60 | 610 | 33 | 20 | ||

| 500 | 20 | 735 | 67 | 673 | 33 | 24 | ||

| 550 | 22 | 785 | 70 | 724 | 33 | 24 | ||

| 600 | 24 | 850 | 76 | 781 | 36 | 24 | ||

Australian Steel Flanges Standards

Australian pipe flange standards ensure the reliable design, material specifications, and dimensional accuracy of flanges used in industrial applications, ensuring safety and performance in piping systems. The primary standard governing flanges in Australia is AS 4087, which defines the requirements for flanges used in pressure piping systems and other critical infrastructure.

-

AS 4087 - Metallic Flanges for Waterworks

This standard defines the design, materials, dimensions, and testing for flanges used in water distribution systems, ensuring compatibility with pressure and temperature requirements. -

AS 2129 - Flanges for Pipes

Outlines specifications for flanges in industries like oil, gas, and petrochemical, including various types (slip-on, weld neck, blind, threaded) and pressure ratings (150, 300, 600, 900, 1500, and 2500). -

AS 2862 - Flanges for Petroleum and Chemical Industries

Tailored for high-temperature and high-pressure systems in the petroleum and chemical industries, with flanges made from corrosion-resistant materials. -

AS 4331 - Flanges for Cast Iron Piping Systems

Specifies flanges for water and sewage systems made from cast iron, designed for lower pressures and offering durability and cost-effectiveness. -

ASME B16.5 - Pipe Flanges and Flanged Fittings

An international standard commonly used in Australia, specifying design, materials, and dimensions for high-pressure flanges made from carbon steel, stainless steel, and alloy steels.

Why Ample Alloys For Australian ASME Flanges !

Ample Alloys is a trusted manufacturer and supplier of high-quality ASME flanges in Australia, offering an unmatched combination of durability, precision, and performance. why Ample Alloys should be your first choice for Australian ASME flanges:

Uncompromising Quality

Ample Alloys guarantees ASME flanges manufactured with top-tier materials, ensuring superior strength, corrosion resistance, and long-lasting performance for demanding applications.

Certified Compliance

We adhere to strict industry standards, including ASME B16.5, B16.47, and B16.1, ensuring that all our flanges are built to meet Australian and international regulations, providing safe and reliable products.

Tailored Solutions

Whether for high-pressure systems, extreme temperatures, or customized materials, Ample Alloys offers bespoke solutions, ensuring precise fit and optimal performance for every application.

Cost-Effective

Ample Alloys provides high-quality ASME flanges at competitive prices, offering the perfect balance of cost savings and reliability, ensuring the best value for your investment.

AS/NZS 4331.1 covers several types of flanges including slip-on flanges, weld neck flanges, and blind flanges, all designed for use in cast iron piping systems. These flanges are typically used in low to medium-pressure systems such as water and wastewater pipelines.

AS/NZS 4331.1 focuses specifically on flanges made from cast iron, offering specifications suited for waterworks and similar applications. It differs from other flange standards, such as ASME or ANSI, which are often used for steel flanges in high-pressure and heavy-duty industrial applications.

While AS/NZS 4331.1 is tailored to Australian and New Zealand markets, flanges manufactured to this standard can often be compatible with other international flange standards, such as ASME or ISO, depending on the application requirements and specific dimensions.