BS 10 Flange Manufacturers

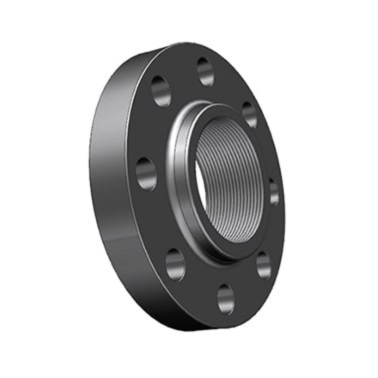

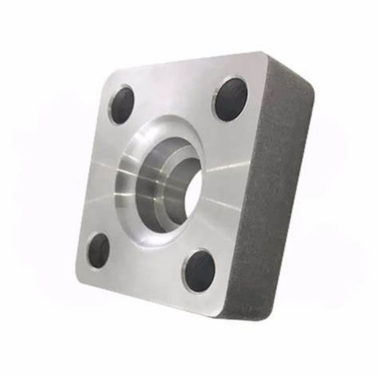

The BS 10 flange is a type of flange standard defined by the British Standard 10 (BS 10) specification. It is commonly used in piping systems to provide a connection between two pipe ends, valves, or other equipment. The flange is used primarily in low-pressure applications and is available in various pressure ratings, such as PN 2.5 to PN 40, depending on the specific requirement. BS 10 also sets guidelines for bolt hole patterns and flange sizes, ensuring compatibility with other components in the pipeline.

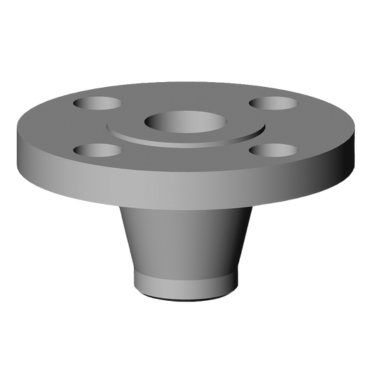

The BS 4504 Flange is a British Standard that specifies the requirements for flanges used in piping systems for a range of industries. This standard covers flanges made from a variety of materials, and is designed to ensure a secure, leak-tight connection in high-pressure and high-temperature applications. BS 4504 flanges are classified into different types based on pressure ratings, which include PN 6, PN 10, PN 16, PN 25, and others. The standard specifies dimensions, materials, and design characteristics for flanges, including welded, slip-on, and blind flanges. These flanges are designed to meet the need for durability, corrosion resistance, and reliability in pipeline systems. The standard ensures compatibility with other components, offering a reliable, standardized approach to flange connections in various industrial settings.

Ample Alloys is a leading manufacturer and supplier of high-quality industrial products, specializing in BS 10 Flange, BS 4504 Flange. With a commitment to excellence, the company provides a wide range of products that meet the highest standards of quality, durability, and performance. The company is known for its strong customer service, ensuring timely delivery and customized solutions to meet specific client requirements. Through strict quality control measures and adherence to international standards, Ample Alloys has earned a reputation for providing reliable and high-performance products, making it a trusted partner for industries worldwide.

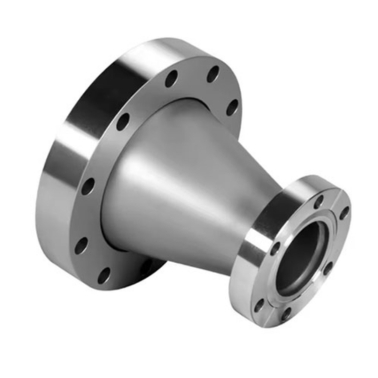

British Standard 10 flange, BS 10 slip-on flange, BS 10 weld neck flange, BS 10 blind flange, BS 10 raised face flange, British Standard 4504 flange, BS 4504 PN10 flanges, BS 4504 slip-on flange, BS 4504 weld neck flange, BS 4504 blind flange, BS 10 Table D Flange, BS 10 Table E, BS 10 Table H Flange, BS 10 Table F Flange, BS10 Table J Flange

BS 10 pipe flange Specifications

Size Range

15mm ( 1/2" NPS ) up to 600mm ( 24" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

BS4504, BS 10

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

PN 2.5 to PN 40 / Table D, Table E, Table F, Table H, Table J.

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

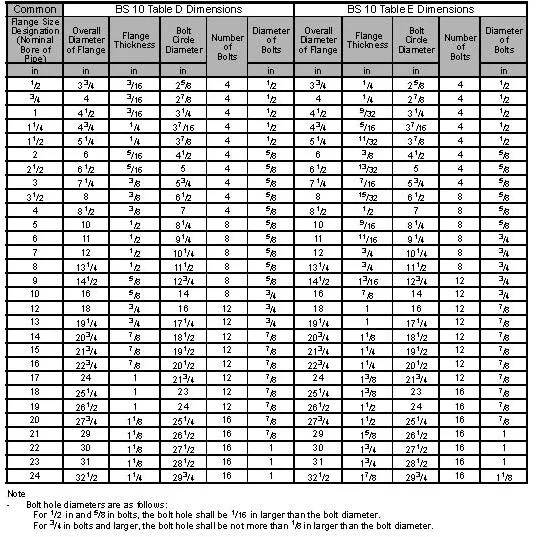

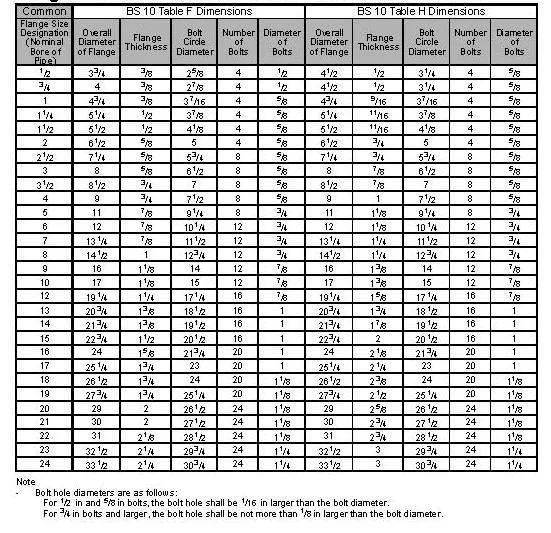

BS 10 Standard Table D,Table E,Table F,Table H Flange - Dimensions & Weight

| DN | A mm | Face Dimensions | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN 2.5 | PN 6 | PN 10 | PN 16 | PN 25 | PN 40 | B mm | C mm | D mm | E mm | a mm | b mm | c mm | d mm | αmm | e mm | |

| 10 | 35 | 35 | 40 | 40 | 40 | 40 | 34 | 35 | 24 | 23 | 2 | 4 | 3 | 2 | – | 5 |

| 15 | 40 | 40 | 45 | 45 | 45 | 45 | 39 | 40 | 29 | 28 | 2 | 4 | 3 | 2 | – | 5 |

| 20 | 50 | 50 | 58 | 58 | 58 | 58 | 50 | 51 | 36 | 35 | 2 | 4 | 3 | 2 | 41°16′ | 5 |

| 25 | 60 | 60 | 68 | 68 | 68 | 68 | 57 | 58 | 43 | 42 | 2 | 4 | 3 | 2 | 41°16′ | 5 |

| 32 | 70 | 70 | 78 | 78 | 78 | 78 | 65 | 66 | 51 | 50 | 2 | 4 | 3 | 2 | 41°16′ | 5 |

| 40 | 80 | 80 | 88 | 88 | 88 | 88 | 75 | 76 | 61 | 60 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 50 | 90 | 90 | 102 | 102 | 102 | 102 | 87 | 88 | 73 | 72 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 65 | 110 | 110 | 122 | 122 | 122 | 122 | 109 | 110 | 95 | 94 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 80 | 128 | 128 | 138 | 138 | 138 | 138 | 120 | 121 | 106 | 105 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 100 | 148 | 148 | 158 | 158 | 162 | 162 | 149 | 150 | 129 | 128 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 125 | 178 | 178 | 188 | 188 | 188 | 188 | 175 | 176 | 155 | 154 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 150 | 202 | 202 | 212 | 212 | 218 | 218 | 203 | 204 | 183 | 182 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 200 | 258 | 258 | 268 | 268 | 278 | 285 | 259 | 260 | 239 | 238 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 250 | 312 | 312 | 320 | 320 | 335 | 345 | 312 | 313 | 292 | 291 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 300 | 365 | 365 | 370 | 378 | 395 | 410 | 363 | 364 | 343 | 342 | 4 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 350 | 415 | 415 | 430 | 438 | 450 | 465 | 421 | 422 | 395 | 394 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 400 | 465 | 465 | 482 | 490 | 505 | 535 | 473 | 474 | 447 | 446 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 450 | 520 | 520 | 532 | 550 | 555 | 560 | 523 | 524 | 497 | 496 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 500 | 570 | 570 | 585 | 610 | 615 | 615 | 575 | 576 | 549 | 548 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 600 | 670 | 670 | 685 | 725 | 720 | 735 | 675 | 676 | 649 | 648 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 700 | 775 | 775 | 800 | 795 | 820 | – | 777 | 778 | 751 | 750 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 800 | 880 | 880 | 905 | 900 | 930 | – | 882 | 883 | 856 | 855 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 900 | 980 | 980 | 1005 | 1000 | 1030 | – | 987 | 988 | 961 | 960 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 1000 | 1080 | 1080 | 1110 | 1115 | 1140 | – | 1092 | 1094 | 1062 | 1060 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1200 | 1280 | 1295 | 1330 | 1330 | 1350 | – | 1292 | 1294 | 1262 | 1260 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1400 | 1480 | 1510 | 1535 | 1530 | 1560 | – | 1492 | 1494 | 1462 | 1460 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1600 | 1690 | 1710 | 1760 | 1750 | 1780 | – | 1692 | 1694 | 1662 | 1660 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1800 | 1890 | 1920 | 1960 | 1950 | 1985 | – | 1982 | 1894 | 1862 | 1860 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 2000 | 2090 | 2125 | 2170 | 2150 | 2210 | – | 2092 | 2094 | 2062 | 2060 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| DN | PN | A | B | C | Bolt Holes | |

|---|---|---|---|---|---|---|

| mm | mm | mm | No. | Bolt size | ||

| 350 | 2.5 & 6 | 490 | 445 | 22 | 12 | M20 |

| 10 | 505 | 460 | 22 | 16 | M20 | |

| 16 | 520 | 470 | 26 | 16 | M24 | |

| 25 | 555 | 490 | 33 | 16 | M30 | |

| 40 | 580 | 510 | 36 | 16 | M33 | |

| 400 | 2.5 & 6 | 540 | 495 | 22 | 16 | M20 |

| 10 | 565 | 515 | 26 | 16 | M24 | |

| 16 | 580 | 525 | 30 | 16 | M27 | |

| 25 | 620 | 550 | 36 | 16 | M33 | |

| 40 | 660 | 585 | 39 | 16 | M36 | |

| 450 | 2.5 & 6 | 595 | 550 | 22 | 16 | M20 |

| 10 | 615 | 565 | 26 | 20 | M24 | |

| 16 | 640 | 585 | 30 | 20 | M27 | |

| 25 | 670 | 600 | 36 | 20 | M33 | |

| 40 | 685 | 610 | 39 | 20 | M36 | |

| 500 | 2.5 & 6 | 645 | 610 | 22 | 20 | M20 |

| 10 | 670 | 620 | 26 | 20 | M24 | |

| 16 | 715 | 650 | 33 | 20 | M30 | |

| 25 | 730 | 660 | 36 | 20 | M33 | |

| 40 | 755 | 670 | 42 | 20 | M39 | |

| 600 | 2.5 & 6 | 755 | 705 | 26 | 20 | M24 |

| 10 | 780 | 725 | 30 | 20 | M27 | |

| 16 | 840 | 770 | 36 | 20 | M33 | |

| 25 | 845 | 770 | 39 | 20 | M36 | |

| 40 | 890 | 795 | 48 | 20 | M45 | |

| 700 | 2.5 & 6 | 860 | 810 | 26 | 24 | M24 |

| 10 | 895 | 840 | 30 | 24 | M27 | |

| 16 | 910 | 840 | 36 | 24 | M33 | |

| 25 | 960 | 875 | 42 | 24 | M39 | |

| 800 | 2.5 & 6 | 975 | 920 | 30 | 24 | M27 |

| 10 | 1015 | 950 | 33 | 24 | M30 | |

| 16 | 1025 | 950 | 39 | 24 | M36 | |

| 25 | 1085 | 990 | 48 | 24 | M45 | |

| 900 | 2.5 & 6 | 1075 | 1020 | 30 | 24 | M27 |

| 10 | 1115 | 1050 | 33 | 28 | M30 | |

| 16 | 1125 | 1050 | 39 | 28 | M36 | |

| 25 | 1185 | 1090 | 48 | 28 | M45 | |

| 1000 | 2.5 & 6 | 1175 | 1120 | 30 | 28 | M27 |

| 10 | 1230 | 1160 | 36 | 28 | M33 | |

| 16 | 1255 | 1170 | 42 | 28 | M39 | |

| 25 | 1320 | 1210 | 56 | 28 | M52 | |

| 1200 | 2.5 | 1375 | 1320 | 30 | 32 | M27 |

| 6 | 1405 | 1340 | 33 | 32 | M30 | |

| 10 | 1455 | 1380 | 39 | 32 | M36 | |

| 16 | 1485 | 1390 | 48 | 32 | M45 | |

| 25 | 1530 | 1420 | 56 | 32 | M52 | |

| 1400 | 2.5 | 1575 | 1520 | 30 | 36 | M27 |

| 6 | 1630 | 1560 | 36 | 36 | M33 | |

| 10 | 1675 | 1590 | 42 | 36 | M39 | |

| 16 | 1685 | 1590 | 48 | 36 | M45 | |

| 25 | 1755 | 1640 | 62 | 36 | M56 | |

| 1600 | 2.5 | 1790 | 1730 | 30 | 40 | M27 |

| 6 | 1830 | 1760 | 36 | 40 | M33 | |

| 10 | 1915 | 1820 | 48 | 40 | M45 | |

| 16 | 1930 | 1820 | 56 | 40 | M52 | |

| 25 | 1975 | 1860 | 62 | 40 | M56 | |

| 1800 | 2.5 | 1990 | 1930 | 30 | 44 | M27 |

| 6 | 2045 | 1970 | 39 | 44 | M36 | |

| 10 | 2115 | 2020 | 48 | 44 | M45 | |

| 16 | 2130 | 2020 | 56 | 44 | M52 | |

| 25 | 2185 | 2070 | 70 | 44 | M64 | |

| 2000 | 2.5 | 2190 | 2130 | 30 | 48 | M27 |

| 6 | 2265 | 2180 | 42 | 48 | M39 | |

| 10 | 2325 | 2230 | 48 | 48 | M45 | |

| 16 | 2345 | 2230 | 62 | 48 | M56 | |

| 25 | 2425 | 2300 | 70 | 48 | M64 | |

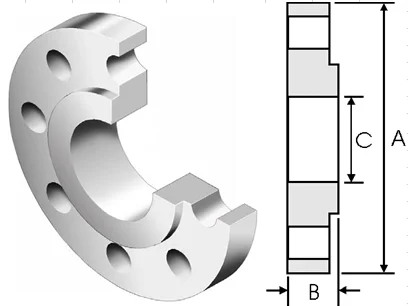

| DN | PN | A mm | B mm | C mm |

|---|---|---|---|---|

| 10 | 2.5, 6 | 75 | 12 | 18 |

| 10 &16 | 90 | 14 | ||

| 25 & 40 | 90 | 14 | ||

| 15 | 2.5 & 6 | 80 | 12 | 22 |

| 10 &16 | 95 | 14 | ||

| 25 & 40 | 95 | 14 | ||

| 20 | 2.5 & 6 | 90 | 14 | 27.5 |

| 10 &16 | 105 | 16 | ||

| 25 & 40 | 105 | 16 | ||

| 25 | 2.5 & 6 | 100 | 14 | 34.5 |

| 10 &16 | 115 | 16 | ||

| 25 & 40 | 115 | 16 | ||

| 32 | 2.5 & 6 | 120 | 16 | 43.5 |

| 10 &16 | 140 | 18 | ||

| 25 & 40 | 140 | 18 | ||

| 40 | 2.5 & 6 | 130 | 16 | 49.5 |

| 10 &16 | 150 | 18 | ||

| 25 & 40 | 150 | 18 | ||

| 50 | 2.5 & 6 | 140 | 16 | 61.5 |

| 10 & 16 | 165 | 20 | ||

| 25 & 40 | 165 | 20 | ||

| 65 | 2.5 & 6 | 160 | 16 | 77.5 |

| 10 & 16 | 185 | 20 | ||

| 25 & 40 | 185 | 22 | ||

| 80 | 2.5 & 6 | 190 | 18 | 90.5 |

| 10 &16 | 200 | 20 | ||

| 25 & 40 | 200 | 24 | ||

| 100 | 2.5 & 6 | 210 | 18 | 116 |

| 10 &16 | 220 | 22 | ||

| 25 & 40 | 235 | 26 | ||

| 125 | 2.5 & 6 | 240 | 20 | 141.5 |

| 10 & 16 | 250 | 22 | ||

| 25 & 40 | 270 | 28 | ||

| 150 | 2.5 & 6 | 265 | 20 | 170.5 |

| 10 & 16 | 285 | 24 | ||

| 25 & 40 | 300 | 30 | ||

| 200 | 2.5 & 6 | 320 | 22 | 221.5 |

| 10 &16 | 340 | 24 | ||

| 25 | 360 | 32 | ||

| 40 | 375 | 36 | ||

| 250 | 2.5 & 6 | 375 | 24 | 276.5 |

| 10 | 395 | 26 | ||

| 16 | 405 | 29 | ||

| 25 | 425 | 35 | ||

| 40 | 450 | 42 | ||

| 300 | 2.5 & 6 | 440 | 24 | 327.5 |

| 10 | 445 | 26 | ||

| 16 | 460 | 32 | ||

| 25 | 485 | 38 | ||

| 40 | 515 | 48 | ||

| 350 | 2.5 & 6 | 490 | 26 | 359.5 |

| 10 | 505 | 28 | ||

| 16 | 520 | 35 | 359 | |

| 25 | 555 | 42 | 359.5 | |

| 40 | 580 | 54 | ||

| 400 | 2.5 & 6 | 540 | 28 | 411 |

| 10 | 565 | 32 | ||

| 16 | 580 | 38 | ||

| 25 | 620 | 46 | ||

| 40 | 660 | 60 | ||

| 450 | 2.5 & 6 | 595 | 30 | 462 |

| 10 | 615 | 36 | ||

| 16 | 640 | 42 | ||

| 25 | 670 | 50 | ||

| 40 | 685 | 66 | ||

| 500 | 2.5 & 6 | 645 | 30 | 513.5 |

| 10 | 670 | 38 | ||

| 16 | 715 | 46 | ||

| 25 | 730 | 56 | ||

| 40 | 755 | 72 | ||

| 600 | 2.5 & 6 | 755 | 32 | 616.5 |

| 10 | 780 | 42 | ||

| 16 | 840 | 52 | ||

| 25 | 845 | 68 | ||

| 40 | 890 | 84 | ||

| 700 | 2.5 | 860 | 36 | To be specifiedby purchaser |

| 800 | 2.5 | 975 | 38 | |

| 900 | 2.5 | 1075 | 40 | |

| 1000 | 2.5 | 1175 | 42 | |

| 1200 | 2.5 | 1375 | 44 | |

| 1400 | 2.5 | 1575 | 48 | |

| 1600 | 2.5 | 1790 | 51 | |

| 1800 | 2.5 | 1990 | 54 | |

| 2000 | 2.5 | 2190 | 58 |

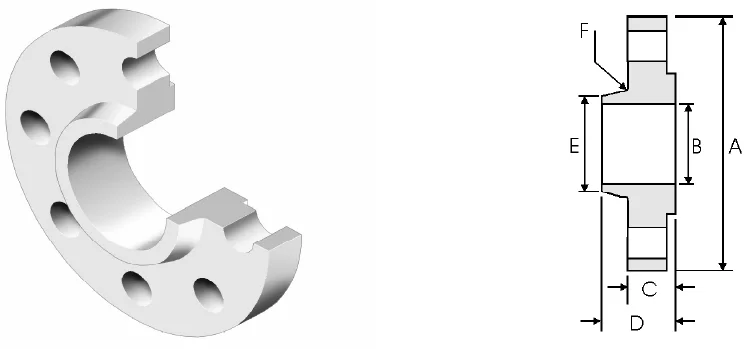

| DN | PN | A mm | B mm | C mm | D mm | E mm | F mm | G mm | H mm |

|---|---|---|---|---|---|---|---|---|---|

| 10 | 2.5,6 | 75 | 17.2 | 12 | 28 | 6 | 26 | 3 | 1.8 |

| 10 | 90 | 14 | 35 | 28 | 1.8 | ||||

| 16 | 90 | 14 | 35 | 28 | 1.8 | ||||

| 25 | 90 | 16 | 35 | 28 | 1.8 | ||||

| 40 | 90 | 16 | 35 | 28 | 1.8 | ||||

| 15 | 2.5,6 | 80 | 21.3 | 12 | 30 | 6 | 30 | 3 | 2 |

| 10 | 95 | 14 | 35 | 32 | 2 | ||||

| 16 | 95 | 14 | 35 | 32 | 2 | ||||

| 25 | 95 | 16 | 38 | 32 | 2 | ||||

| 40 | 95 | 16 | 38 | 32 | 2 | ||||

| 20 | 2.5,6 | 90 | 26.9 | 14 | 32 | 6 | 38 | 4 | 2.3 |

| 10 | 105 | 16 | 38 | 39 | 2.3 | ||||

| 16 | 105 | 16 | 38 | 39 | 2.3 | ||||

| 25 | 105 | 18 | 40 | 40 | 2.3 | ||||

| 40 | 105 | 18 | 40 | 40 | 2.3 | ||||

| 25 | 2.5,6 | 100 | 33.7 | 14 | 35 | 6 | 42 | 4 | 2.6 |

| 10 | 115 | 16 | 38 | 46 | 2.6 | ||||

| 16 | 115 | 16 | 38 | 46 | 2.6 | ||||

| 25 | 115 | 18 | 40 | 46 | 2.6 | ||||

| 40 | 115 | 18 | 40 | 46 | 2.6 | ||||

| 32 | 2.5,6 | 120 | 42.4 | 14 | 35 | 6 | 55 | 5 | 2.6 |

| 10 | 140 | 16 | 40 | 56 | 2.6 | ||||

| 16 | 140 | 16 | 40 | 56 | 2.6 | ||||

| 25 | 140 | 18 | 42 | 56 | 2.6 | ||||

| 40 | 140 | 18 | 42 | 56 | 2.6 | ||||

| 40 | 2.5,6 | 130 | 48.3 | 14 | 38 | 7 | 62 | 5 | 2.6 |

| 10 | 150 | 16 | 42 | 64 | 2.6 | ||||

| 16 | 150 | 16 | 42 | 64 | 2.6 | ||||

| 25 | 150 | 18 | 45 | 64 | 2.6 | ||||

| 40 | 150 | 18 | 45 | 64 | 2.6 | ||||

| 50 | 2.5,6 | 140 | 60.3 | 14 | 38 | 8 | 74 | 5 | 2.9 |

| 10 | 165 | 18 | 45 | 74 | 2.9 | ||||

| 16 | 165 | 18 | 45 | 74 | 2.9 | ||||

| 25 | 165 | 20 | 48 | 74 | 2.9 | ||||

| 40 | 165 | 20 | 48 | 74 | 2.9 | ||||

| 65 | 2.5,6 | 160 | 76.1 | 14 | 38 | 9 | 88 | 6 | 2.9 |

| 10 | 185 | 18 | 45 | 10 | 92 | 2.9 | |||

| 16 | 185 | 18 | 45 | 92 | 2.9 | ||||

| 25 | 185 | 22 | 52 | 92 | 2.9 | ||||

| 40 | 185 | 22 | 52 | 92 | 2.9 | ||||

| 80 | 2.5,6 | 190 | 88.9 | 16 | 42 | 10 | 102 | 6 | 3.2 |

| 10 | 200 | 20 | 50 | 110 | 3.2 | ||||

| 16 | 200 | 20 | 50 | 12 | 110 | 3.2 | |||

| 25 | 200 | 24 | 58 | 110 | 3.2 | ||||

| 40 | 200 | 24 | 58 | 110 | 3.2 |

| DN | PN | A mm | B mm | C mm | D mm | E mm | F mm |

| 200 | 6 | 320 | 221.5 | 20 | 44 | 240 | 8 |

| 10 &16 | 340 | 24 | 44 | 246 | |||

| 25 | 360 | 30 | 52 | 256 | |||

| 40 | 375 | 34 | 52 | 260 | |||

| 250 | 6 | 375 | 276.5 | 22 | 44 | 295 | 10 |

| 10 | 395 | 26 | 46 | 298 | |||

| 16 | 405 | 26 | 46 | 298 | |||

| 25 | 425 | 32 | 60 | 310 | |||

| 40 | 450 | 38 | 60 | 312 | |||

| 300 | 6 | 440 | 327.5 | 22 | 44 | 355 | 10 |

| 10 | 445 | 26 | 46 | 350 | |||

| 16 | 460 | 28 | 46 | 350 | |||

| 25 | 485 | 34 | 67 | 364 | |||

| 40 | 515 | 42 | 67 | 380 | |||

| 350 | 10 | 505 | 359.5 | 26 | 53 | 400 | 10 |

| 16 | 520 | 359 | 30 | 57 | 400 | ||

| 25 | 555 | 359.5 | 38 | 72 | 418 | ||

| 40 | 580 | 46 | 72 | 424 | |||

| 400 | 10 | 565 | 411 | 26 | 57 | 456 | 10 |

| 16 | 580 | 32 | 63 | 456 | |||

| 25 | 620 | 40 | 78 | 472 | |||

| 40 | 660 | 50 | 78 | 478 | |||

| 450 | 10 | 615 | 462 | 28 | 63 | 502 | 12 |

| 16 | 640 | 34 | 68 | 502 | |||

| 25 | 670 | 42 | 84 | 520 | |||

| 40 | 685 | 50 | 84 | 522 | |||

| 500 | 10 | 670 | 513.5 | 28 | 67 | 559 | 12 |

| 16 | 715 | 34 | 73 | 559 | |||

| 25 | 730 | 44 | 90 | 580 | |||

| 40 | 755 | 52 | 90 | 576 | |||

| 600 | 10 | 780 | 616.5 | 28 | 75 | 658 | 12 |

| 16 | 840 | 36 | 83 | 658 | |||

| 25 | 845 | 46 | 100 | 684 | |||

| 40 | 890 | 60 | 100 | 686 |

| DN | PN | A mm | B mm | C mm | D mm | E mm |

|---|---|---|---|---|---|---|

| 10 | 6 | 75 | 25 | 12 | 20 | 3 |

| 16 | 90 | 30 | 14 | 20 | ||

| 40 | 90 | 30 | 16 | 22 | ||

| 15 | 6 | 80 | 30 | 12 | 20 | 3 |

| 16 | 95 | 35 | 14 | 20 | ||

| 40 | 95 | 35 | 16 | 22 | ||

| 20 | 6 | 90 | 40 | 14 | 24 | 4 |

| 16 | 105 | 45 | 16 | 24 | ||

| 40 | 105 | 45 | 18 | 26 | ||

| 25 | 6 | 100 | 50 | 14 | 24 | 4 |

| 16 | 115 | 52 | 16 | 24 | ||

| 40 | 115 | 52 | 18 | 28 | ||

| 32 | 6 | 120 | 60 | 14 | 26 | 5 |

| 16 | 140 | 60 | 16 | 26 | ||

| 40 | 140 | 60 | 18 | 30 | ||

| 40 | 6 | 130 | 70 | 14 | 26 | 5 |

| 16 | 150 | 70 | 16 | 26 | ||

| 40 | 150 | 70 | 18 | 32 | ||

| 50 | 6 | 140 | 80 | 14 | 28 | 5 |

| 16 | 165 | 84 | 18 | 28 | ||

| 40 | 165 | 84 | 20 | 34 | ||

| 65 | 6 | 160 | 100 | 14 | 32 | 6 |

| 16 | 185 | 104 | 18 | 32 | ||

| 40 | 185 | 104 | 22 | 38 | ||

| 80 | 6 | 190 | 110 | 16 | 34 | 6 |

| 16 | 200 | 118 | 20 | 34 | ||

| 40 | 200 | 118 | 24 | 40 | ||

| 100 | 6 | 210 | 130 | 16 | 40 | 6 |

| 16 | 220 | 140 | 20 | 40 | ||

| 40 | 235 | 145 | 24 | 44 |

| DN | PN | A mm | B mm | C mm | D mm | E mm |

|---|---|---|---|---|---|---|

| 125 | 6 | 240 | 160 | 18 | 44 | 6 |

| 16 | 250 | 168 | 22 | 44 | ||

| 40 | 270 | 170 | 26 | 48 | ||

| 150 | 6 | 265 | 185 | 18 | 44 | 8 |

| 16 | 285 | 195 | 22 | 44 | ||

| 40 | 300 | 200 | 28 | 52 | ||

| 200 | 6 | 320 | 240 | 20 | 44 | 8 |

| 16 | 340 | 246 | 24 | 44 | ||

| 40 | 375 | 260 | 34 | 52 | ||

| 250 | 6 | 375 | 295 | 22 | 44 | 10 |

| 16 | 405 | 298 | 26 | 46 | ||

| 40 | 450 | 312 | 38 | 60 | ||

| 300 | 6 | 440 | 355 | 22 | 44 | 10 |

| 16 | 460 | 350 | 28 | 46 | ||

| 40 | 515 | 380 | 42 | 67 | ||

| 350 | 16 | 520 | 400 | 30 | 57 | 10 |

| 40 | 580 | 424 | 46 | 72 | ||

| 400 | 16 | 580 | 456 | 32 | 63 | 10 |

| 40 | 660 | 478 | 50 | 78 | ||

| 450 | 16 | 640 | 502 | 34 | 68 | 12 |

| 40 | 685 | 522 | 50 | 84 | ||

| 500 | 16 | 715 | 559 | 34 | 73 | 12 |

| 40 | 755 | 576 | 52 | 90 | ||

| 600 | 16 | 840 | 658 | 36 | 83 | 12 |

| 40 | 890 | 686 | 60 | 100 | ||

| 700 | 16 | 910 | 760 | 36 | 83 | 12 |

| 800 | 16 | 1025 | 864 | 38 | 90 | 12 |

| 900 | 16 | 1125 | 968 | 40 | 94 | 12 |

| 1000 | 16 | 1255 | 1072 | 42 | 100 | 12 |

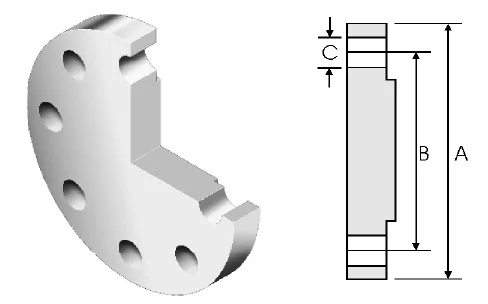

| DN | PN | A mm | B mm | C mm |

|---|---|---|---|---|

| 10 | 2.5, 6 | 75 | 12 | – |

| 10 &16 | 90 | 14 | – | |

| 25 & 40 | 90 | 16 | – | |

| 15 | 2.5 & 6 | 80 | 12 | – |

| 10 &16 | 95 | 14 | – | |

| 25 & 40 | 95 | 16 | – | |

| 20 | 2.5 & 6 | 90 | 14 | – |

| 10 &16 | 105 | 16 | – | |

| 25 & 40 | 105 | 18 | – | |

| 25 | 2.5 & 6 | 100 | 14 | – |

| 10 &16 | 115 | 16 | – | |

| 25 & 40 | 115 | 18 | – | |

| 32 | 2.5 & 6 | 120 | 14 | – |

| 10 &16 | 140 | 16 | – | |

| 25 & 40 | 140 | 18 | – | |

| 40 | 2.5 & 6 | 130 | 14 | – |

| 10 &16 | 150 | 16 | – | |

| 25 & 40 | 150 | 18 | – | |

| 50 | 2.5 & 6 | 140 | 14 | – |

| 10 & 16 | 165 | 18 | – | |

| 25 & 40 | 165 | 20 | – | |

| 65 | 2.5 & 6 | 160 | 14 | 55 |

| 10 & 16 | 185 | 18 | 55 | |

| 25 & 40 | 185 | 22 | 55 | |

| 80 | 2.5 & 6 | 190 | 16 | 70 |

| 10 &16 | 200 | 20 | 70 | |

| 25&40 | 200 | 24 | 70 | |

| 100 | 2.5 & 6 | 210 | 16 | 90 |

| 10 &16 | 220 | 20 | 90 | |

| 25&40 | 235 | 24 | 90 | |

| 125 | 2.5 & 6 | 240 | 18 | 115 |

| 10 & 16 | 250 | 22 | 115 | |

| 25 & 40 | 270 | 26 | 115 | |

| 150 | 2.5 & 6 | 265 | 18 | 140 |

| 10 & 16 | 285 | 22 | 140 | |

| 25 & 40 | 300 | 28 | 140 | |

| 200 | 2.5 & 6 | 320 | 20 | 190 |

| 10 &16 | 340 | 24 | 190 | |

| 25 | 360 | 30 | 190 | |

| 40 | 375 | 34 | 190 | |

| 250 | 2.5 & 6 | 375 | 22 | 235 |

| 10 | 395 | 26 | 235 | |

| 16 | 405 | 26 | 235 | |

| 25 | 425 | 32 | 235 | |

| 40 | 450 | 38 | 235 |

| DN | PN | A mm | B mm | C mm |

|---|---|---|---|---|

| 300 | 2.5 & 6 | 440 | 22 | 285 |

| 10 | 445 | 26 | 285 | |

| 16 | 460 | 28 | 285 | |

| 25 | 485 | 34 | 285 | |

| 40 | 515 | 42 | 285 | |

| 350 | 2.5 & 6 | 490 | 22 | 325 |

| 10 | 505 | 26 | 325 | |

| 16 | 520 | 30 | 325 | |

| 25 | 555 | 38 | 325 | |

| 40 | 580 | 46 | 325 | |

| 400 | 2.5 & 6 | 540 | 22 | 375 |

| 10 | 565 | 26 | 375 | |

| 16 | 580 | 32 | 375 | |

| 25 | 620 | 40 | 375 | |

| 40 | 660 | 50 | 375 | |

| 450 | 2.5 & 6 | 595 | 24 | 425 |

| 10 | 615 | 28 | 425 | |

| 16 | 640 | 34 | 425 | |

| 25 | 670 | 42 | 425 | |

| 40 | 685 | 54 | 425 | |

| 500 | 2.5 & 6 | 645 | 24 | 475 |

| 10 | 670 | 28 | 475 | |

| 16 | 715 | 36 | 475 | |

| 25 | 730 | 45 | 475 | |

| 40 | 755 | 56 | 475 | |

| 600 | 2.5 & 6 | 755 | 34 | 575 |

| 10 | 780 | 34 | 575 | |

| 16 | 840 | 44 | 575 | |

| 25 | 845 | 54 | 575 | |

| 40 | 890 | 70 | 575 | |

| 700 | 2.5 | 860 | 36 | – |

| 6 | 860 | 38 | – | |

| 10 | 895 | 38 | 670 | |

| 16 | 910 | 48 | 670 | |

| 800 | 2.5 | 975 | 38 | – |

| 6 | 975 | 42 | – | |

| 10 | 1015 | 42 | 770 | |

| 16 | 1025 | 52 | 770 | |

| 900 | 2.5 | 1075 | 40 | – |

| 6 | 1075 | 46 | – | |

| 10 | 1115 | 46 | 860 | |

| 16 | 1125 | 58 | 860 | |

| 1000 | 2.5 | 1175 | 42 | – |

| 6 | 1175 | 52 | – | |

| 10 | 1230 | 52 | 960 | |

| 16 | 1255 | 64 | 960 | |

| 1200 | 2.5 | 1375 | 44 | – |

| 6 | 1405 | 60 | – | |

| 10 | 1455 | 60 | 1160 | |

| 16 | 1485 | 76 | 1160 | |

| 1400 | 2.5 | 1575 | 48 | – |

| 6 | 1630 | 68 | – | |

| 1600 | 2.5 | 1790 | 51 | – |

| 6 | 1830 | 76 | – | |

| 1800 | 2.5 | 1990 | 54 | – |

| 6 | 2045 | 84 | – | |

| 2000 | 2.5 | 2190 | 58 | – |

| 6 | 2265 | 92 | – |

BS 10 flanged fittings Standards

The BS 10 flanged fittings are governed by British Standard 10, which defines the specifications and requirements for flanges used in piping systems. The standards are essential for ensuring the flanges are manufactured to certain dimensions, pressure ratings, and material specifications to suit various applications.

- BS Standards (British)

- BS 4504 – Circular Flanges for Pipes, Valves, and Fittings.

- BS 10 – Specification for Flanges and Bolting.

- Material-Specific Standards (ASTM)

- ASTM A105 – Carbon Steel Forged Flanges.

- ASTM A182 – Alloy and Stainless Steel Forged Flanges.

- ASTM A350 – Carbon and Low-Alloy Steel Flanges for Low-Temperature Service.

- ASTM A694 – High-Strength Carbon and Alloy Steel Flanges for High-Pressure Applications.

- Other Regional and Specialized Standards

- KS B1511 – Korean Standard Flanges.

- NF E29-206 – French Standard Flanges.

- SANS 1123 – South African Standard for Steel Flanges.

Why Ample Alloys For BS 4504 flange!

Ample Alloys ensures that every BS 4504 flange meets the required dimensions, pressure ratings, and material specifications for optimal performance in various industrial applications.

High-Quality Standards

Ample Alloys ensures that all BS 4504 flanges are manufactured to meet international quality standards, ensuring reliability and durability.

Precision Manufacturing

Our BS 4504 flanges are produced with precise dimensions, pressure ratings, and material specifications for consistent performance.

Experienced Supplier

With years of experience in the industry, Ample Alloys has earned a reputation for providing top-quality flanges.

Competitive Pricing

We offer cost-effective solutions without compromising on quality, making us a trusted choice for businesses.

BS 10 flanges come with different pressure ratings ranging from PN 2.5 to PN 40. BS 4504 flanges cover pressure ratings up to PN 63 or higher, depending on the specific flange design and application.

While they are designed to meet British standards, BS 10 and BS 4504 flanges can often be used in conjunction with other international flange standards such as ASME or ANSI, though compatibility should be confirmed based on specific dimensions and pressure ratings.

BS 10 flanges are used in lower-pressure systems, while BS 4504 flanges are designed for higher-pressure systems and more demanding applications.