AWWA C207 Flanges Manufacturers

AWWA Flange refers to flanges manufactured according to the standards set by the American Water Works Association (AWWA), a key organization in the water utility industry. These flanges are specifically designed for use in water treatment, distribution systems, and wastewater management applications. The AWWA flanges are generally used to connect pipes, valves, and other fittings in water pipelines to ensure leak-free, secure joints that can withstand the pressure and environmental conditions of water systems.

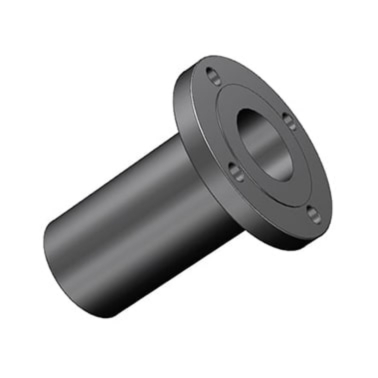

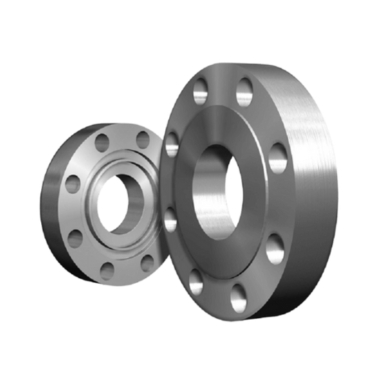

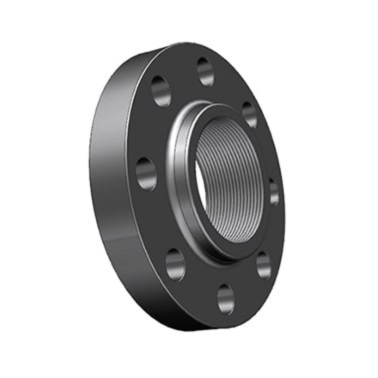

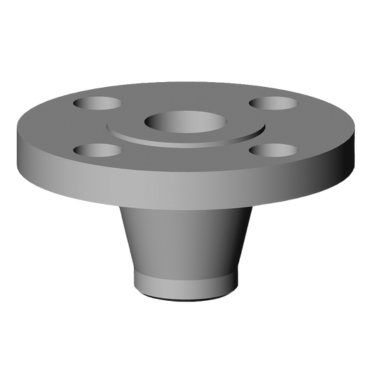

AWWA flanges are typically made from materials such as ductile iron, carbon steel, or stainless steel, offering excellent resistance to corrosion and ensuring longevity in both potable and non-potable water systems. The most common types of AWWA flanges include ring flanges and slip-on flanges, with designs that ensure ease of installation, maintenance, and reliable performance in waterworks.

The AWWA standards, such as AWWA C207, define specifications for flange dimensions, pressure ratings, and material characteristics, ensuring uniformity and compatibility across different manufacturers and applications. These flanges are crucial for maintaining the integrity of water pipelines and ensuring the smooth flow of water in municipal and industrial water systems.

AWWA C207 Claas Class B, Class D, Class E, And Class F Flange, AWWA C228 Flange, AWWA C115 Flange, AWWA C200 Flange, AWWA C600 Flange, AWWA D100 Flange, AWWA C504 Flange, AWWA M55 Flange, AWWA C651 Flange, AWWA C900 Flange

AWWA C207 Flanges Specifications

Size Range

15mm ( 1/2" NPS ) up to 1200 mm ( 48" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

AWWA (American Water Works Association)

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

Class B, Class D, Class E, and Class F

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

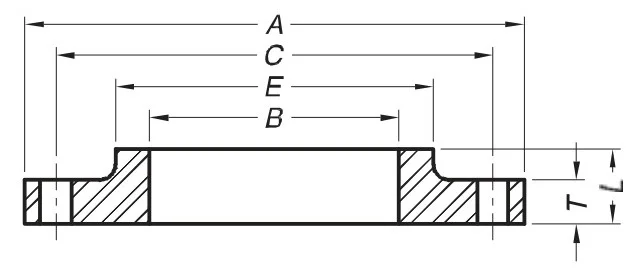

| NPS | DN | OD, A | ID, B | Number of Bolts | Diam.of Bolt Circle, C | Diam.of Bolt | T | L | E |

|---|---|---|---|---|---|---|---|---|---|

| 4 | 100 | 228.60 | 116.08 | 8 | 190.50 | 15.88 | 12.70 | 22.23 | 134.92 |

| 5 | 125 | 254.00 | 143.76 | 8 | 215.90 | 19.05 | 14.27 | 31.75 | 160.32 |

| 6 | 150 | 279.40 | 170.69 | 8 | 241.30 | 19.05 | 14.27 | 31.75 | 192.07 |

| 8 | 200 | 342.90 | 221.49 | 8 | 298.45 | 19.05 | 14.27 | 31.75 | 246.08 |

| 10 | 250 | 406.40 | 276.35 | 12 | 361.95 | 22.23 | 17.48 | 31.75 | 304.80 |

| 12 | 300 | 482.60 | 327.15 | 12 | 431.80 | 22.23 | 17.48 | 31.75 | 365.13 |

| 14 | 350 | 533.40 | 360.43 | 12 | 476.25 | 25.40 | 19.05 | 31.75 | 400.05 |

| 16 | 400 | 596.90 | 411.23 | 16 | 539.75 | 25.40 | 19.05 | 31.75 | 457.20 |

| 18 | 450 | 635.00 | 462.03 | 16 | 577.85 | 28.58 | 19.05 | 31.75 | 504.83 |

| 20 | 500 | 698.50 | 512.83 | 20 | 635.00 | 28.58 | 19.05 | 31.75 | 558.80 |

| 22 | 550 | 749.30 | 563.63 | 20 | 692.15 | 31.75 | 25.40 | 44.45 | 615.95 |

| 24 | 600 | 812.80 | 614.43 | 20 | 749.30 | 31.75 | 25.40 | 44.45 | 663.58 |

| 26 | 650 | 869.95 | 665.23 | 24 | 806.45 | 31.75 | 25.40 | 44.45 | 723.90 |

| 28 | 700 | 927.10 | 716.03 | 28 | 863.60 | 31.75 | 25.40 | 44.45 | 774.70 |

| 30 | 750 | 984.25 | 766.83 | 28 | 914.40 | 31.75 | 25.40 | 44.45 | 825.50 |

| 32 | 800 | 1060.45 | 817.63 | 28 | 977.90 | 38.10 | 28.58 | 44.45 | 882.65 |

| 34 | 850 | 1111.25 | 868.43 | 32 | 1028.70 | 38.10 | 28.58 | 44.45 | 933.45 |

| 36 | 900 | 1168.40 | 919.23 | 32 | 1085.85 | 38.10 | 28.58 | 44.45 | 984.25 |

| 38 | 950 | 1238.25 | 970.03 | 32 | 1149.35 | 38.10 | 28.58 | 44.45 | 1035.05 |

| 40 | 1000 | 1289.05 | 1020.83 | 36 | 1200.15 | 38.10 | 28.58 | 44.45 | 1092.20 |

| 42 | 1050 | 1346.20 | 1071.63 | 36 | 1257.30 | 38.10 | 31.75 | 44.45 | 1143.00 |

| 44 | 1100 | 1403.35 | 1122.43 | 40 | 1314.45 | 38.10 | 31.75 | 57.15 | 1193.80 |

| 46 | 1150 | 1454.15 | 1173.23 | 40 | 1365.25 | 38.10 | 31.75 | 57.15 | 1244.60 |

| 48 | 1200 | 1511.30 | 1224.03 | 44 | 1422.40 | 38.10 | 34.93 | 63.50 | 1295.40 |

| 50 | 1250 | 1568.45 | 1274.83 | 44 | 1479.55 | 44.45 | 34.93 | 63.50 | 1346.20 |

| 52 | 1300 | 1625.60 | 1325.63 | 44 | 1536.70 | 44.45 | 34.93 | 63.50 | 1397.00 |

| 54 | 1350 | 1682.75 | 1376.43 | 44 | 1593.85 | 44.45 | 34.93 | 63.50 | 1447.80 |

| 60 | 1500 | 1854.20 | 1528.83 | 52 | 1758.95 | 44.45 | 38.10 | 69.85 | 1600.20 |

| 66 | 1650 | 2032.00 | 1681.23 | 52 | 1930.40 | 44.45 | 38.10 | 69.85 | 1752.60 |

| 72 | 1800 | 2197.10 | 1833.63 | 60 | 2095.50 | 44.45 | 38.10 | 69.85 | 1905.00 |

| 78 | 1950 | 2362.20 | 1986.03 | 64 | 2260.60 | 50.80 | 44.45 | 76.20 | 2063.75 |

| 84 | 2100 | 2533.65 | 2138.43 | 64 | 2425.70 | 50.80 | 44.45 | 76.20 | 2222.50 |

| 90 | 2250 | 2705.10 | 2290.83 | 68 | 2590.80 | 57.15 | 50.80 | 82.55 | 2381.25 |

| 96 | 2400 | 2876.55 | 2443.23 | 68 | 2755.90 | 57.15 | 50.80 | 82.55 | 2540.00 |

| NPS | DN | OD, A | ID, B | Number of Bolts | Diam.of Bolt Circle, C | Diam.of Bolt | T | L | E |

|---|---|---|---|---|---|---|---|---|---|

| 4 | 100 | 228.60 | 116.08 | 8 | 190.50 | 15.88 | 23.83 | 33.32 | 134.92 |

| 5 | 125 | 254.00 | 143.76 | 8 | 215.90 | 19.05 | 23.83 | 36.53 | 163.53 |

| 6 | 150 | 279.40 | 170.69 | 8 | 241.30 | 19.05 | 25.40 | 39.67 | 192.07 |

| 8 | 200 | 342.90 | 221.49 | 8 | 298.45 | 19.05 | 28.58 | 44.45 | 246.08 |

| 10 | 250 | 406.40 | 276.35 | 12 | 361.95 | 22.23 | 30.18 | 49.23 | 304.80 |

| 12 | 300 | 482.60 | 327.15 | 12 | 431.80 | 22.23 | 31.75 | 55.58 | 365.13 |

| 14 | 350 | 533.40 | 360.43 | 12 | 476.25 | 25.40 | 34.93 | 57.15 | 400.05 |

| 16 | 400 | 596.90 | 411.23 | 16 | 539.75 | 25.40 | 36.53 | 63.50 | 457.20 |

| 18 | 450 | 635.00 | 462.03 | 16 | 577.85 | 28.58 | 39.67 | 68.28 | 504.83 |

| 20 | 500 | 698.50 | 512.83 | 20 | 635.00 | 28.58 | 42.88 | 73.03 | 558.80 |

| 22 | 550 | 749.30 | 563.63 | 20 | 692.15 | 31.75 | 46.02 | 79.38 | 609.60 |

| 24 | 600 | 812.80 | 614.43 | 20 | 749.30 | 31.75 | 48.20 | 82.55 | 663.58 |

| 26 | 650 | 869.95 | 665.23 | 24 | 806.45 | 31.75 | 50.80 | 85.73 | 723.90 |

| 28 | 700 | 927.10 | 716.03 | 28 | 863.60 | 31.75 | 52.37 | 87.33 | 781.05 |

| 30 | 750 | 984.25 | 766.83 | 28 | 914.40 | 31.75 | 53.98 | 88.90 | 831.85 |

| 32 | 800 | 1060.45 | 817.63 | 28 | 977.90 | 38.10 | 57.15 | 92.08 | 889.00 |

| 34 | 850 | 1111.25 | 868.43 | 32 | 1028.70 | 38.10 | 58.72 | 93.68 | 939.80 |

| 36 | 900 | 1168.40 | 919.23 | 32 | 1085.85 | 38.10 | 60.33 | 95.25 | 996.95 |

| 38 | 950 | 1238.25 | 970.03 | 32 | 1149.35 | 38.10 | 60.33 | 95.25 | 1060.45 |

| 40 | 1000 | 1289.05 | 1020.83 | 36 | 1200.15 | 38.10 | 63.50 | 98.43 | 1111.25 |

| 42 | 1050 | 1346.20 | 1071.63 | 36 | 1257.30 | 38.10 | 66.68 | 101.60 | 1168.40 |

| 44 | 1100 | 1403.35 | 1122.43 | 40 | 1314.45 | 38.10 | 66.68 | 101.60 | 1219.20 |

| 46 | 1150 | 1454.15 | 1173.23 | 40 | 1365.25 | 38.10 | 68.28 | 103.17 | 1270.00 |

| 48 | 1200 | 1511.30 | 1224.03 | 44 | 1422.40 | 38.10 | 69.85 | 104.78 | 1327.15 |

| 50 | 1250 | 1568.45 | 1274.83 | 44 | 1479.55 | 44.45 | 69.85 | 104.78 | 1377.95 |

| 52 | 1300 | 1625.60 | 1325.63 | 44 | 1536.70 | 44.45 | 73.03 | 107.95 | 1435.10 |

| 54 | 1350 | 1682.75 | 1376.43 | 44 | 1593.85 | 44.45 | 76.20 | 111.13 | 1492.25 |

| 60 | 1500 | 1854.20 | 1528.83 | 52 | 1758.95 | 44.45 | 79.38 | 114.30 | 1657.35 |

| 66 | 1650 | 2032.00 | 1681.23 | 52 | 1930.40 | 44.45 | 85.73 | 123.83 | 1816.10 |

| 72 | 1800 | 2197.10 | 1833.63 | 60 | 2095.50 | 44.45 | 88.90 | 127.00 | 1993.90 |

| 78 | 1950 | 2362.20 | 1986.03 | 64 | 2260.60 | 50.80 | 98.43 | 136.53 | 2146.30 |

| 84 | 2100 | 2533.65 | 2138.43 | 64 | 2425.70 | 50.80 | 98.43 | 136.53 | 2298.70 |

| 90 | 2250 | 2705.10 | 2290.83 | 68 | 2590.80 | 57.15 | 107.95 | 146.05 | 2457.45 |

| 96 | 2400 | 2876.55 | 2443.23 | 68 | 2755.90 | 57.15 | 107.95 | 146.05 | 2609.85 |

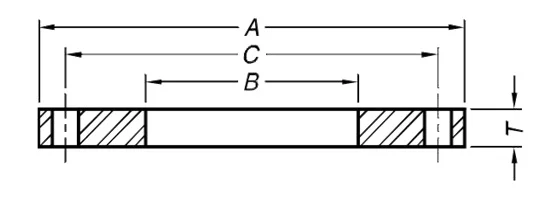

| NPS | DN | OD, A | ID, B | Number of Bolts | Diam.of Bolt Circle, C | Diam.of Bolt | Thickness of Flange, T | Thickness of Blind, T |

|---|---|---|---|---|---|---|---|---|

| 4 | 100 | 228.60 | 116.08 | 8 | 190.50 | 15.88 | 15.88 | 15.88 |

| 5 | 125 | 254.00 | 143.76 | 8 | 215.90 | 19.05 | 15.88 | 15.88 |

| 6 | 150 | 279.40 | 170.69 | 8 | 241.30 | 19.05 | 17.48 | 17.48 |

| 8 | 200 | 342.90 | 221.49 | 8 | 298.45 | 19.05 | 17.48 | 17.48 |

| 10 | 250 | 406.40 | 276.35 | 12 | 361.95 | 22.23 | 17.48 | 17.48 |

| 12 | 300 | 482.60 | 327.15 | 12 | 431.80 | 22.23 | 17.48 | 18.26 |

| 14 | 350 | 533.40 | 360.43 | 12 | 476.25 | 25.40 | 17.48 | 20.1 |

| 16 | 400 | 596.90 | 411.23 | 16 | 539.75 | 25.40 | 17.48 | 22.66 |

| 18 | 450 | 635.00 | 462.03 | 16 | 577.85 | 28.58 | 17.48 | 24.13 |

| 20 | 500 | 698.50 | 512.83 | 20 | 635.00 | 28.58 | 17.48 | 26.42 |

| 22 | 550 | 749.30 | 563.63 | 20 | 692.15 | 31.75 | 19.05 | 28.74 |

| 24 | 600 | 812.80 | 614.43 | 20 | 749.30 | 31.75 | 19.05 | 30.89 |

| 26 | 650 | 869.95 | 24 | 806.45 | 31.75 | 20.62 | 33.2 | |

| 28 | 700 | 927.10 | 28 | 863.60 | 31.75 | 22.23 | 35.5 | |

| 30 | 750 | 984.25 | 28 | 914.40 | 31.75 | 22.23 | 37.53 | |

| 32 | 800 | 1060.45 | 28 | 977.90 | 38.10 | 23.83 | 40.16 | |

| 34 | 850 | 1111.25 | 32 | 1028.70 | 38.10 | 23.83 | 42.19 | |

| 36 | 900 | 1168.40 | 32 | 1085.85 | 38.10 | 25.40 | 44.48 | |

| 38 | 950 | 1238.25 | 32 | 1149.35 | 38.10 | 25.40 | 47.06 | |

| 40 | 1000 | 1289.05 | 36 | 1200.15 | 38.10 | 25.40 | 49.09 | |

| 42 | 1050 | 1346.20 | 36 | 1257.30 | 38.10 | 28.58 | 51.4 | |

| 44 | 1100 | 1403.35 | 40 | 1314.45 | 38.10 | 28.58 | 53.7 | |

| 46 | 1150 | 1454.15 | 40 | 1365.25 | 38.10 | 28.58 | 55.73 | |

| 48 | 1200 | 1511.30 | 44 | 1422.40 | 38.10 | 31.75 | 58.03 | |

| 50 | 1250 | 1568.45 | 44 | 1479.55 | 44.45 | 31.75 | 60.38 | |

| 52 | 1300 | 1625.60 | 44 | 1536.70 | 44.45 | 31.75 | 62.69 | |

| 54 | 1350 | 1682.75 | 44 | 1593.85 | 44.45 | 34.93 | 64.99 | |

| 60 | 1500 | 1854.20 | 52 | 1758.95 | 44.45 | 38.10 | 71.63 | |

| 66 | 1650 | 2032.00 | 52 | 1930.40 | 44.45 | 41.28 | 78.53 | |

| 72 | 1800 | 2197.10 | 60 | 2095.50 | 44.45 | 44.45 | 85.17 | |

| 78 | 1950 | 2362.20 | 64 | 2260.60 | 50.80 | 50.80 | ||

| 84 | 2100 | 2533.65 | 64 | 2425.70 | 50.80 | 50.80 | ||

| 90 | 2250 | 2705.10 | 68 | 2590.80 | 57.15 | 57.15 | ||

| 96 | 2400 | 2876.55 | 68 | 2755.90 | 57.15 | 57.15 | ||

| 102 | 2550 | 3048.00 | 72 | 2908.30 | 63.50 | 63.50 | ||

| 108 | 2700 | 3219.45 | 72 | 3067.05 | 63.50 | 63.50 | ||

| 114 | 2850 | 3390.90 | 76 | 3219.45 | 69.85 | 69.85 | ||

| 120 | 3000 | 3562.35 | 76 | 3371.85 | 69.85 | 69.85 | ||

| 126 | 3150 | 3733.80 | 80 | 3536.95 | 76.20 | 76.20 | ||

| 132 | 3300 | 3905.25 | 80 | 3702.05 | 76.20 | 76.20 | ||

| 144 | 3600 | 4248.15 | 84 | 4019.55 | 82.55 | 82.55 |

| NPS | DN | OD, A | ID, B | Number of Bolts | Diam.of Bolt Circle, C | Diam.of Bolt | Thickness of Flange, T | Thickness of Blind, T |

|---|---|---|---|---|---|---|---|---|

| 4 | 100 | 228.60 | 116.08 | 8 | 190.50 | 15.88 | 15.88 | 15.88 |

| 5 | 125 | 254.00 | 143.76 | 8 | 215.90 | 19.05 | 15.88 | 16.51 |

| 6 | 150 | 279.40 | 170.69 | 8 | 241.30 | 19.05 | 17.48 | 17.59 |

| 8 | 200 | 342.90 | 221.49 | 8 | 298.45 | 19.05 | 17.48 | 20.62 |

| 10 | 250 | 406.40 | 276.35 | 12 | 361.95 | 22.23 | 17.48 | 24.21 |

| 12 | 300 | 482.60 | 327.15 | 12 | 431.80 | 22.23 | 20.62 | 28.37 |

| 14 | 350 | 533.40 | 360.43 | 12 | 476.25 | 25.40 | 23.83 | 28.78 |

| 16 | 400 | 596.90 | 411.23 | 16 | 539.75 | 25.40 | 25.40 | 32.13 |

| 18 | 450 | 635.00 | 462.03 | 16 | 577.85 | 28.58 | 26.97 | 33.81 |

| 20 | 500 | 698.50 | 512.83 | 20 | 635.00 | 28.58 | 28.58 | 36.77 |

| 22 | 550 | 749.30 | 563.63 | 20 | 692.15 | 31.75 | 30.18 | 39.83 |

| 24 | 600 | 812.80 | 614.43 | 20 | 749.30 | 31.75 | 31.75 | 42.18 |

| 26 | 650 | 869.95 | 24 | 806.45 | 31.75 | 33.32 | 45.37 | |

| 28 | 700 | 927.10 | 28 | 863.60 | 31.75 | 33.32 | 48.4 | |

| 30 | 750 | 984.25 | 28 | 914.40 | 31.75 | 34.93 | 51 | |

| 32 | 800 | 1060.45 | 28 | 977.90 | 38.10 | 38.10 | 54.6 | |

| 34 | 850 | 1111.25 | 32 | 1028.70 | 38.10 | 38.10 | 57.21 | |

| 36 | 900 | 1168.40 | 32 | 1085.85 | 38.10 | 41.28 | 60.2 | |

| 38 | 950 | 1238.25 | 32 | 1149.35 | 38.10 | 41.28 | 63.66 | |

| 40 | 1000 | 1289.05 | 36 | 1200.15 | 38.10 | 41.28 | 66.28 | |

| 42 | 1050 | 1346.20 | 36 | 1257.30 | 38.10 | 44.45 | 69.32 | |

| 44 | 1100 | 1403.35 | 40 | 1314.45 | 38.10 | 44.45 | 72.36 | |

| 46 | 1150 | 1454.15 | 40 | 1365.25 | 38.10 | 44.45 | 74.99 | |

| 48 | 1200 | 1511.30 | 44 | 1422.40 | 38.10 | 47.63 | 78.03 | |

| 50 | 1250 | 1568.45 | 44 | 1479.55 | 44.45 | 50.80 | 81.18 | |

| 52 | 1300 | 1625.60 | 44 | 1536.70 | 44.45 | 50.80 | 84.21 | |

| 54 | 1350 | 1682.75 | 44 | 1593.85 | 44.45 | 53.98 | 87.25 | |

| 60 | 1500 | 1854.20 | 52 | 1758.95 | 44.45 | 57.15 | 95.97 | |

| 66 | 1650 | 2032.00 | 52 | 1930.40 | 44.45 | 63.50 | 105.6 | |

| 72 | 1800 | 2197.10 | 60 | 2095.50 | 44.45 | 66.68 | 113.8 | |

| 78 | 1950 | 2362.20 | 64 | 2260.60 | 50.80 | 69.85 | ||

| 84 | 2100 | 2533.65 | 64 | 2425.70 | 50.80 | 73.03 | ||

| 90 | 2250 | 2705.10 | 68 | 2590.80 | 57.15 | 76.20 | ||

| 96 | 2400 | 2876.55 | 68 | 2755.90 | 57.15 | 82.55 | ||

| 102 | 2550 | 3048.00 | 72 | 2908.30 | 63.50 | 82.55 | ||

| 108 | 2700 | 3219.45 | 72 | 3067.05 | 63.50 | 85.73 | ||

| 114 | 2850 | 3390.90 | 76 | 3219.45 | 69.85 | 88.90 | ||

| 120 | 3000 | 3562.35 | 76 | 3371.85 | 69.85 | 88.90 | ||

| 126 | 3150 | 3733.80 | 80 | 3536.95 | 76.20 | 95.25 | ||

| 132 | 3300 | 3905.25 | 80 | 3702.05 | 76.20 | 98.43 | ||

| 144 | 3600 | 4248.15 | 84 | 4019.55 | 82.55 | 104.78 |

| NPS | DN | OD, A | ID, B | Number of Bolts | Diam.of Bolt Circle, C | Diam.of Bolt | Thickness of Flange, T | Thickness of Blind, T |

|---|---|---|---|---|---|---|---|---|

| 4 | 100 | 228.60 | 116.08 | 8 | 190.50 | 15.88 | 15.88 | 28.58 |

| 5 | 125 | 254.00 | 143.76 | 8 | 215.90 | 19.05 | 19.05 | 30.18 |

| 6 | 150 | 279.40 | 170.69 | 8 | 241.30 | 19.05 | 19.05 | 33.35 |

| 8 | 200 | 342.90 | 221.49 | 8 | 298.45 | 19.05 | 19.05 | 38.1 |

| 10 | 250 | 406.40 | 276.35 | 12 | 361.95 | 22.23 | 22.23 | 39.7 |

| 12 | 300 | 482.60 | 327.15 | 12 | 431.80 | 22.23 | 22.23 | 44.45 |

| 14 | 350 | 533.40 | 360.43 | 12 | 476.25 | 25.40 | 25.40 | 47.63 |

| 16 | 400 | 596.90 | 411.23 | 16 | 539.75 | 25.40 | 25.40 | 50.8 |

| 18 | 450 | 635.00 | 462.03 | 16 | 577.85 | 28.58 | 28.58 | 53.98 |

| 20 | 500 | 698.50 | 512.83 | 20 | 635.00 | 28.58 | 28.58 | 60.33 |

| 22 | 550 | 749.30 | 563.63 | 20 | 692.15 | 31.75 | 31.75 | 63.5 |

| 24 | 600 | 812.80 | 614.43 | 20 | 749.30 | 31.75 | 31.75 | 66.68 |

| 26 | 650 | 869.95 | 24 | 806.45 | 31.75 | 31.75 | 69.85 | |

| 28 | 700 | 927.10 | 28 | 863.60 | 31.75 | 31.75 | 69.85 | |

| 30 | 750 | 984.25 | 28 | 914.40 | 31.75 | 31.75 | 73.03 | |

| 32 | 800 | 1060.45 | 28 | 977.90 | 38.10 | 38.10 | 76.2 | |

| 34 | 850 | 1111.25 | 32 | 1028.70 | 38.10 | 38.10 | 77.46 | |

| 36 | 900 | 1168.40 | 32 | 1085.85 | 38.10 | 38.10 | 81.51 | |

| 38 | 950 | 1238.25 | 32 | 1149.35 | 38.10 | 38.10 | 86.2 | |

| 40 | 1000 | 1289.05 | 36 | 1200.15 | 38.10 | 38.10 | 89.74 | |

| 42 | 1050 | 1346.20 | 36 | 1257.30 | 38.10 | 38.10 | 93.86 | |

| 44 | 1100 | 1403.35 | 40 | 1314.45 | 38.10 | 38.10 | 97.97 | |

| 46 | 1150 | 1454.15 | 40 | 1365.25 | 38.10 | 38.10 | 101.53 | |

| 48 | 1200 | 1511.30 | 44 | 1422.40 | 38.10 | 38.10 | 105.65 | |

| 50 | 1250 | 1568.45 | 44 | 1479.55 | 44.45 | 44.45 | 109.9 | |

| 52 | 1300 | 1625.60 | 44 | 1536.70 | 44.45 | 44.45 | 114.02 | |

| 54 | 1350 | 1682.75 | 44 | 1593.85 | 44.45 | 44.45 | 118.14 | |

| 60 | 1500 | 1854.20 | 52 | 1758.95 | 44.45 | 44.45 | 129.95 | |

| 66 | 1650 | 2032.00 | 52 | 1930.40 | 44.45 | 44.45 | 142.26 | |

| 72 | 1800 | 2197.10 | 60 | 2095.50 | 44.45 | 44.45 | 154.08 | |

| 78 | 1950 | 2362.20 | 64 | 2260.60 | 50.80 | 50.80 | ||

| 84 | 2100 | 2533.65 | 64 | 2425.70 | 50.80 | 50.80 | ||

| 90 | 2250 | 2705.10 | 68 | 2590.80 | 57.15 | 57.15 | ||

| 96 | 2400 | 2876.55 | 68 | 2755.90 | 57.15 | 57.15 | ||

| 102 | 2550 | 3048.00 | 72 | 2908.30 | 63.50 | 63.50 | ||

| 108 | 2700 | 3219.45 | 72 | 3067.05 | 63.50 | 63.50 | ||

| 114 | 2850 | 3390.90 | 76 | 3219.45 | 69.85 | 69.85 | ||

| 120 | 3000 | 3562.35 | 76 | 3371.85 | 69.85 | 69.85 | ||

| 126 | 3150 | 3733.80 | 80 | 3536.95 | 76.20 | 76.20 | ||

| 132 | 3300 | 3905.25 | 80 | 3702.05 | 76.20 | 76.20 | ||

| 144 | 3600 | 4248.15 | 84 | 4019.55 | 82.55 | 82.55 |

| NPS | DN | OD, A | ID, B | Number of Bolts | Diam.of Bolt Circle, C | Diam.of Bolt | Thickness of Flange, T | Thickness of Blind, T |

|---|---|---|---|---|---|---|---|---|

| 4 | 100 | 254.00 | 116.08 | 8 | 200.15 | 19.05 | 28.70 | 28.7 |

| 5 | 125 | 279.40 | 143.76 | 8 | 234.95 | 19.05 | 30.73 | 30.73 |

| 6 | 150 | 317.50 | 170.94 | 12 | 269.75 | 19.05 | 33.27 | 33.27 |

| 8 | 200 | 381.00 | 221.74 | 12 | 330.20 | 22.23 | 33.27 | 33.27 |

| 10 | 250 | 444.50 | 276.35 | 16 | 387.35 | 25.40 | 38.10 | 38.1 |

| 12 | 300 | 520.70 | 327.15 | 16 | 450.85 | 28.58 | 41.40 | 41.4 |

| 14 | 350 | 584.20 | 360.43 | 20 | 514.35 | 28.58 | 49.28 | 49.28 |

| 16 | 400 | 647.70 | 411.23 | 20 | 571.50 | 31.75 | 54.36 | 54.36 |

| 18 | 450 | 711.20 | 462.03 | 24 | 628.65 | 31.75 | 57.15 | 57.125 |

| 20 | 500 | 774.70 | 512.83 | 24 | 685.80 | 31.75 | 59.18 | 59.18 |

| 22 | 550 | 838.20 | 563.63 | 24 | 742.95 | 31.75 | 63.50 | 63.5 |

| 24 | 600 | 914.40 | 614.43 | 24 | 812.80 | 38.10 | 68.33 | 68.53 |

| 26 | 650 | 971.55 | 28 | 876.30 | 44.45 | 76.20 | 76.2 | |

| 28 | 700 | 1035.05 | 28 | 939.80 | 44.45 | 79.50 | 79.5 | |

| 30 | 750 | 1092.20 | 28 | 996.95 | 44.45 | 80.01 | 80.42 | |

| 32 | 800 | 1149.35 | 28 | 1054.10 | 44.45 | 82.55 | 84.62 | |

| 34 | 850 | 1206.50 | 28 | 1104.90 | 44.45 | 85.85 | 88.25 | |

| 36 | 900 | 1270.00 | 32 | 1168.40 | 50.80 | 87.88 | 93.25 | |

| 38 | 950 | 1327.15 | 32 | 1219.20 | 50.80 | 88.90 | 96.9 | |

| 40 | 1000 | 1377.95 | 36 | 1276.35 | 50.80 | 92.20 | 101.4 | |

| 42 | 1050 | 1447.80 | 36 | 1339.85 | 50.80 | 96.77 | 105.92 | |

| 44 | 1100 | 1504.95 | 36 | 1397.00 | 50.80 | 101.60 | 110.19 | |

| 46 | 1150 | 1562.10 | 40 | 1454.15 | 50.80 | 104.90 | 114.43 | |

| 48 | 1200 | 1651.00 | 40 | 1543.05 | 50.80 | 114.30 | 121.44 |

AWWA C228 Flange Standards

The AWWA C228 standard ensures that ductile iron flanges used in waterworks are reliable, durable, and compatible with the broader network of water distribution components, helping to maintain the smooth operation of municipal and industrial water systems.

- AWWA C207 – Specifies steel ring flanges for water pipeline connections, including dimensions and pressure ratings.

- AWWA C110 – Covers ductile and gray iron fittings, including design and material specifications for water pipelines.

- AWWA C151 – Specifies requirements for ductile iron pipes, including material, dimensions, and pressure ratings for water distribution.

- AWWA C153 – Covers compact ductile iron fittings, focusing on weight reduction and installation flexibility for waterworks.

- AWWA C219 – Defines requirements for mechanical-joint restraints to secure fittings and joints under pressure.

- AWWA C222 – Outlines cement-mortar linings and coatings for steel pipes to enhance corrosion resistance and durability.

- AWWA C228 – Specifies flanged ductile iron fittings for water distribution, detailing material and pressure ratings.

- AWWA C300 – Covers reinforced concrete pressure pipes for large-diameter water transmission systems, with design and testing specifications.

- AWWA C306 – Details requirements for prestressed concrete pressure pipes, ensuring strength for high-pressure applications.

- AWWA C400 – Specifies fiberglass pressure pipes, covering design, manufacturing, and installation for water distribution.

- AWWA C500 – Defines specifications for gate valves in waterworks, including materials, design, and performance characteristics.

- AWWA C508 – Covers swing check valves to prevent backflow in water pipelines, detailing design and performance requirements.

Why Ample Alloys For AWWA Flange Standard!

We are trusted provider for AWWA flanges, offering a range of benefits that make us the go-to choice for industries requiring high-quality, reliable flanges.

Commitment to Quality

Ample Alloys ensures AWWA flanges meet rigorous industry standards for durability and reliability in waterworks applications.

Customization Options

Provides custom solutions, including special sizes, pressure ratings, and flange face types.

Competitive Pricing

High-quality AWWA flanges at competitive prices, offering cost-effective solutions for waterworks projects.

Expert Support

Technical experts guide material selection, flange specifications, and other requirements for waterworks systems.

AWWA flanges are typically made from materials such as carbon steel, stainless steel, ductile iron, and sometimes other alloys, depending on the application and environmental conditions.

Yes, AWWA flanges can be customized to meet specific project requirements, including special sizes, pressure ratings, and flange face types.

AWWA flanges are compatible with other standards such as ANSI, ASME, and DIN, but it's important to verify compatibility for specific applications, especially for large-scale projects.