ASME / ANSI B16.5, B16.47 High Hub Blind Raised Face Flange Manufacturers

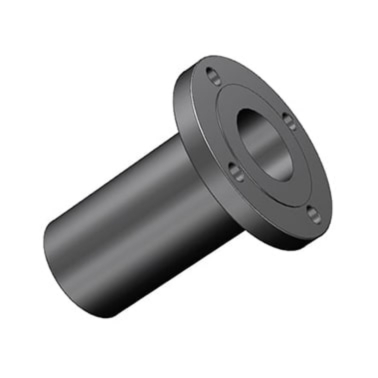

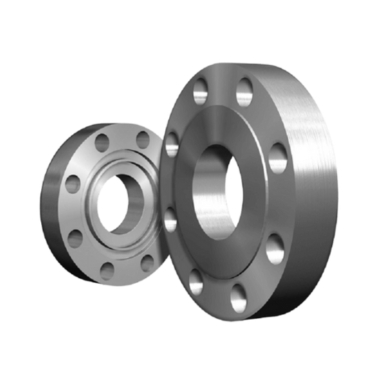

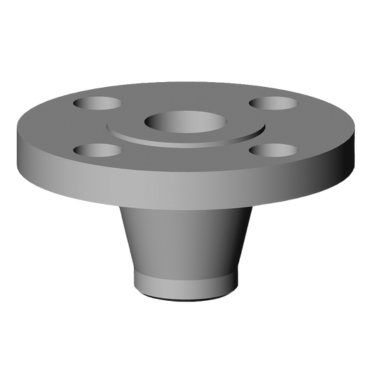

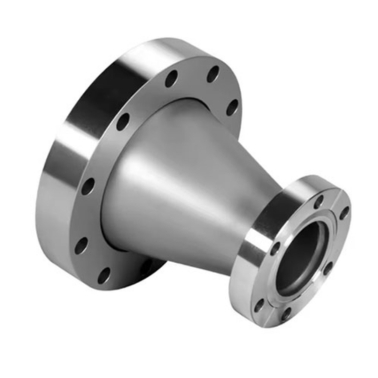

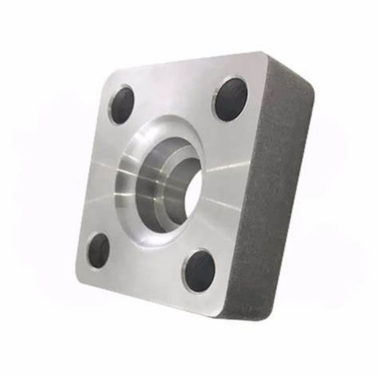

Blind Flanges and high hub blind flanges are integral components in piping systems used to block off or seal the ends of pipelines, valves, or other equipment. A blind flange is a solid flange without a bore, providing a secure closure to prevent the flow of fluids or gases while allowing easy access for maintenance or extension of the pipeline. A high hub blind flange is a specialized version of a blind flange designed with an extended hub for additional strength and durability in high-pressure and high-temperature applications. The hub adds mechanical stability, making it suitable for critical operations where enhanced sealing and structural integrity are essential. Both types of flanges are manufactured to international standards like ASME, ANSI, DIN, and EN, offering versatility and reliability across a broad range of applications.

At Ample Alloys, we specialize in providing high-quality blind flanges that are designed to meet the most stringent industry standards. With years of experience in manufacturing and supplying flanges, we are dedicated to delivering products that offer exceptional performance, durability, and reliability. Our blind flanges are crafted from premium materials such as carbon steel, stainless steel, duplex steel, and other high-alloy materials to ensure compatibility with various applications, including oil & gas, petrochemical, power generation, and water treatment.

Stainless Steel, Alloy Steel High Hub Blind Flange, API 6A High Hub Blind Flange, DIN High Hub Blind Flange, High Hub Blind Flange PN16, Class 150 High Hub Blind Flange, High Hub Blind Flange DN50, Forged High Hub Blind Flange, High Hub Blind Flange PN16, Carbon Steel High Hub Blind Flange

ASME B16.5 High Hub Blind Flange

Size Range

15mm ( 1/2" NPS ) up to 600mm ( 24" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

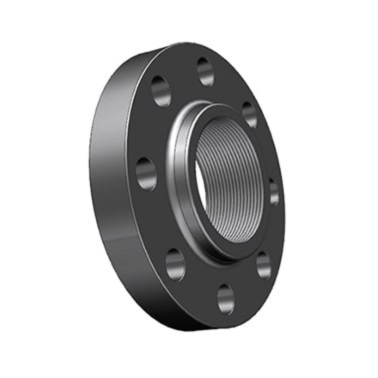

Flange Face Type

FF—Flat Face, RF—Raised Face, FM—Female Face, M—Male Face, T—Tongue Face, G—Groove Face, RJ—Ring Joint.

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64.

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

| Item ID | Class 150 HH High Hub Blind Flanges Description |

|---|---|

| 1FF .51RHHBLD | 1/2 150 RF HIGH HUB BLIND ASME B16.5 001 lbs |

| 1FF .751RHHBL | 3/4 150 RF HIGH HUB BLIND ASME B16.5 002 lbs |

| 1FF 11RHHBL | 1 150 RF HIGH HUB BLIND ASME B16.5 002 lbs |

| 1FF 1.51RHHBL | 1 1/2 150 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF 21RHHBL | 2 150 RF HIGH HUB BLIND ASME B16.5 005 lbs |

| 1FF 31RHHBL | 3 150 RF HIGH HUB BLIND ASME B16.5 009 lbs |

| 1FF 41RHHBL | 4 150 RF HIGH HUB BLIND ASME B16.5 017 lbs |

| Item ID | Class 300 HH High Hub Blind Flanges Description |

|---|---|

| 1FF .53RHHBL | 1/2 300 RF HIGH HUB BLIND ASME B16.5 002 lbs |

| 1FF .753RHHBL | 3/4 300 RF HIGH HUB BLIND ASME B16.5 003 lbs |

| 1FF 13RHHBL | 1 300 RF HIGH HUB BLIND ASME B16.5 003 lbs |

| 1FF 1.53RHHBL | 1 1/2 300 RF HIGH HUB BLIND ASME B16.5 006 lbs |

| 1FF 23RHHBL | 2 300 RF HIGH HUB BLIND ASME B16.5 008 lbs |

| Item ID | Class 600 HH High Hub Blind Flanges Description |

|---|---|

| 1FF .756RHHBL | 3/4 600 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF .56RHHBL | 1/2 600 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF 16RHHBL | 1 600 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF 1.56RHHBL | 1 1/2 600 RF HIGH HUB BLIND ASME B16.5 008 lbs |

| 1FF 26RHHBL | 2 600 RF HIGH HUB BLIND ASME B16.5 010 lbs |

High Hub Blind Flange Standards

High hub blind flanges are essential components in various industrial piping systems, particularly in applications where pressure containment and sealing are crucial. These flanges adhere to several international standards to ensure consistency, reliability, and performance across different industries.

- ASME/ANSI Standards (American):

- ASME B16.5 – Pipe Flanges and Flanged Fittings (NPS 1/2" to 24").

- ASME B16.47 – Large Diameter Steel Flanges (Series A & B, NPS 26" to 60").

- ASME B16.36 – Orifice Flanges.

- ASME B16.48 – Line Blanks (Spectacle, Spade, and Spacer Flanges).

- ANSI B16.1 – Cast Iron Flanges and Flanged Fittings.

- ANSI B16.42 – Ductile Iron Pipe Flanges and Flanged Fittings.

- ISO Standards (International)

- ISO 7005-1 – Steel Flanges for General Applications.

- ISO 7005-2 – Cast Iron Flanges.

- ISO 7005-3 – Copper Alloy Flanges.

- EN Standards (European)

- EN 1092-1 – Steel Flanges.

- EN 1092-2 – Cast Iron Flanges.

- EN 1092-3 – Copper Alloy Flanges.

- EN 1092-4 – Aluminium Alloy Flanges.

- DIN Standards (German)

- DIN 2527 – Blind Flanges.

- DIN 2576 – Slip-On Flanges (PN 10).

- DIN 2633 – Weld Neck Flanges (PN 16).

- DIN 2634 – Weld Neck Flanges (PN 25).

- DIN 2635 – Weld Neck Flanges (PN 40).

- JIS Standards (Japanese)

- JIS B2220 – Steel Pipe Flanges.

- GOST Standards (Russian)

- GOST 12820 – Flat Flanges for Steel Pipe Joints.

- GOST 12821 – Steel Welded Flanges for High-Pressure Applications.

- GOST 33259 – Flange Connections for Industrial Equipment and Pipelines.

- BS Standards (British)

- BS 4504 – Circular Flanges for Pipes, Valves, and Fittings.

- BS 10 – Specification for Flanges and Bolting.

- API Standards (Oil & Gas)

- API 6A – Wellhead and Christmas Tree Equipment Flanges.

- API 605 – Large-Diameter Carbon Steel Flanges (merged into ASME B16.47 Series B).

- AWWA Standards (Waterworks)

- AWWA C207 – Steel Ring Flanges for Waterworks Service.

- MSS Standards (Manufacturer's Standardization Society)

- MSS SP-44 – Steel Pipe Flanges (merged into ASME B16.47 Series A).

- MSS SP-51 – Flanges for Glass-Lined Equipment.

- Material-Specific Standards (ASTM)

- ASTM A105 – Carbon Steel Forged Flanges.

- ASTM A182 – Alloy and Stainless Steel Forged Flanges.

- ASTM A350 – Carbon and Low-Alloy Steel Flanges for Low-Temperature Service.

- ASTM A694 – High-Strength Carbon and Alloy Steel Flanges for High-Pressure Applications.

- Other Regional and Specialized Standards

- KS B1511 – Korean Standard Flanges.

- NF E29-206 – French Standard Flanges.

- SANS 1123 – South African Standard for Steel Flanges.

Why Ample Alloys For ANSI B16.5 High Hub Blind Flange!

Choosing Ample Alloys for your ANSI B16.5 High Hub Blind Flange needs means investing in top-tier quality, customization, and a partner dedicated to meeting your industrial requirements. With our attention to detail, unmatched expertise, and focus on customer satisfaction, we are the ideal supplier for your blind flange solutions.

Compliance with Industry Standards

Our ANSI B16.5 High Hub Blind Flanges meet strict ANSI B16.5 specifications, ensuring reliability and suitability for applications.

Customization & Precision Engineering

Our flanges are tailored to your specific dimensions, pressure ratings, and material needs, ensuring precise performance.

Extensive Industry Experience

With years of experience, we deliver high-quality flanges designed for reliability in every industry.

Competitive Pricing & On-Time Delivery

We offer great pricing and efficient delivery, ensuring your projects stay on track.

The main difference between a High Hub Blind Flange and a standard blind flange is the raised center hub. The high hub design enhances strength, stability, and alignment, especially in high-pressure systems, while a standard blind flange is flat and is typically used for lower pressure applications.

- Increased strength and stability in high-pressure systems.

- Improved alignment during installation.

- Better sealing performance due to the raised hub.

- Durability and long-lasting reliability in demanding environments.

- Oil & Gas

- Petrochemical

- Power Generation

- Chemical Processing

- Water Treatment These industries require high-pressure sealing solutions to ensure system integrity and safety.