Korean Standard Flanges, KS B1503 5k, 10k, 16k, 20k Flange

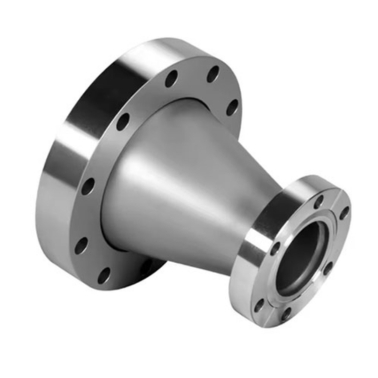

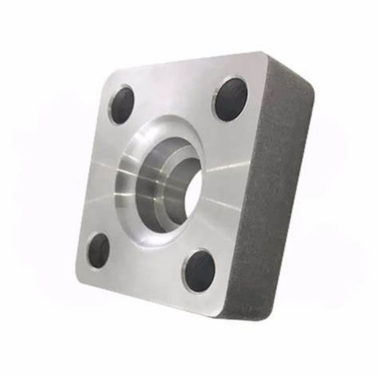

Korean standard flanges are a critical component in industrial piping systems, known for their high-quality manufacturing and precision engineering. These flanges adhere to international standards like JIS (Japanese Industrial Standards) and KS (Korean Standards), ensuring reliability and performance in various applications, Korean standard flanges are designed to withstand high-pressure, high-temperature, and corrosive environments. With stringent quality control measures in place, these flanges offer excellent sealing properties, making them ideal for securing piping connections and ensuring system integrity. Whether it’s weld neck, slip-on, or blind flanges, Korean standard flanges provide exceptional durability, precision, and cost-efficiency for a wide range of industries.

Ample Alloys is a leading manufacturer and supplier of Korean standard flanges, offering high-quality products that adhere to both JIS (Japanese Industrial Standards) and KS (Korean Standards). With years of experience in the industry, we provide a comprehensive range of flanges including weld neck, slip-on, blind, and threaded options, tailored to meet the demands of various industrial applications. At Ample Alloys, we are committed to providing reliable, cost-effective solutions with on-time delivery and unparalleled customer support. Whether you're working in oil & gas, petrochemical, power generation, or any other industry, Ample Alloys is your trusted partner for all your Korean flange needs.

KOSHA certified flanges, Korean forged flanges, Korean pipe flanges, KSA flanges, Korean custom flanges, Carbon steel Korean flanges, JIS Korean flanges, Ks B1503 Blind Flange and Ks B1503 Slip On Flange

Korean steel flanges Specifications

Size Range

15mm ( 1/2" NPS ) up to 1200 mm ( 48" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

Flange Face Type

Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ)

Stainless Steel

ASTM A182 F 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 310, 310S, 347, 904L, etc.

Standards / Dimension

KS B 1501, KS D 1501, JIS B2220

Carbon Steel

ASTM A105/A105N (SA105N), LTCS A350 LF2, A694

Alloy Steel

ASTM A182 / SA182 - F1 / F5 / F9 / F11 / F12 / F22 / F91

Pressure Class

Class 150, Class 300, Class 600, Class 900, Class 1500 and Class 2500.

Duplex & Super Duplex

ASTM A182 / ASME SA182 - S31803, S32205, 2205, S32750, S32760, S32950, 2507.

MTC

EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103

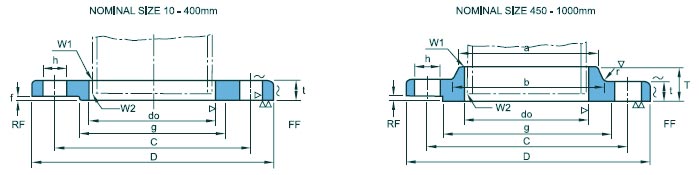

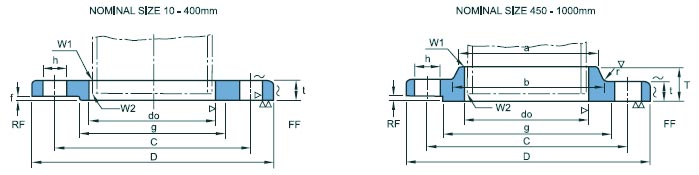

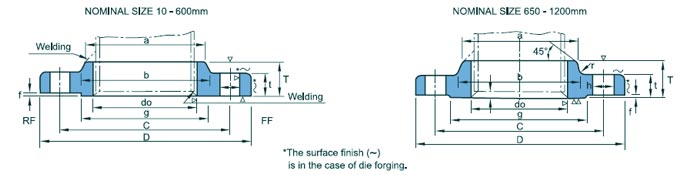

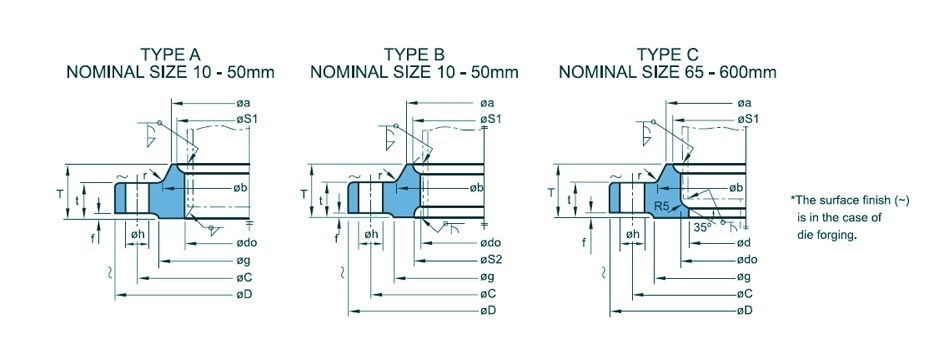

| Nominal Diameter of Flanges | Outside Diameter of Flanges D | flange Sectional Dimensions | Size Of Bolt | Welding | ||||||||||||

| Diameter of Bolt Circle C | Diameter Of raised Face g | Inside Dia. Of Flange do | Outside Diameter Of Applicable pipe | t | T | Hub Diameter | Radius r | Raised Face f | Hole Diameter Of H | Bolt Holes Number | ||||||

| a | b | W1 | W2 | |||||||||||||

| 10 | 75 | 55 | 39 | 17.8 | 17.3 | 9 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 2.5 |

| 15 | 80 | 60 | 44 | 22.2 | 21.7 | 9 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 3 |

| 20 | 85 | 65 | 49 | 27.7 | 27.2 | 10 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 3 |

| 25 | 95 | 75 | 59 | 34.5 | 34 | 10 | – | – | – | – | 1 | 12 | 4 | M10 | 5 | 3 |

| 32 | 115 | 90 | 70 | 43.2 | 42.7 | 12 | – | – | – | – | 2 | 15 | 4 | M12 | 6 | 3 |

| 40 | 120 | 95 | 75 | 49.1 | 48.6 | 12 | – | – | – | – | 2 | 15 | 4 | M12 | 6 | 3 |

| 50 | 130 | 105 | 85 | 61.1 | 60.5 | 14 | 2 | 15 | 4 | M12 | 6 | 3 | ||||

| 65 | 155 | 130 | 110 | 77.1 | 76.3 | 14 | 2 | 15 | 4 | M12 | 6 | 4 | ||||

| 80 | 180 | 145 | 121 | 90 | 89.1 | 14 | 2 | 19 | 4 | M16 | 6 | 4 | ||||

| 90 | 190 | 155 | 131 | 102.6 | 101.6 | 14 | 2 | 19 | 4 | M16 | 6 | 4 | ||||

| 100 | 200 | 165 | 141 | 115.4 | 114.3 | 16 | 2 | 19 | 8 | M16 | 7 | 4 | ||||

| 125 | 235 | 200 | 176 | 141.2 | 139.8 | 16 | 2 | 19 | 8 | M16 | 7 | 4 | ||||

| 150 | 265 | 230 | 206 | 166.6 | 165.2 | 18 | 2 | 19 | 8 | M16 | 7 | 5 | ||||

| 175 | 300 | 260 | 232 | 192.1 | 190.7 | 18 | 2 | 23 | 8 | M20 | 7.5 | 5 | ||||

| 200 | 320 | 280 | 252 | 218 | 216.3 | 20 | 2 | 23 | 8 | M20 | 8.5 | 6 | ||||

| 225 | 345 | 305 | 277 | 243.7 | 241.8 | 20 | 2 | 23 | 12 | M20 | 9 | 6 | ||||

| 250 | 385 | 345 | 317 | 269.5 | 267.4 | 22 | 2 | 23 | 12 | M20 | 10 | 6 | ||||

| 300 | 430 | 390 | 360 | 321 | 318.5 | 22 | 3 | 23 | 12 | M20 | 10 | 6 | ||||

| 350 | 480 | 435 | 403 | 358.1 | 355.6 | 24 | 3 | 25 | 12 | M22 | 12 | 7 | ||||

| 400 | 540 | 495 | 463 | 409 | 406.4 | 24 | 3 | 25 | 16 | M22 | 12 | 7 | ||||

| 450 | 605 | 555 | 523 | 460 | 457.2 | 24 | 40 | 495 | 500 | 5 | 3 | 25 | 16 | M22 | 12 | 7 |

| 500 | 655 | 605 | 573 | 511 | 508 | 24 | 40 | 546 | 552 | 5 | 3 | 25 | 20 | M22 | 12 | 7 |

| 550 | 720 | 665 | 630 | 562 | 558.8 | 26 | 42 | 597 | 603 | 5 | 3 | 27 | 20 | M24 | 12 | 7 |

| 600 | 770 | 715 | 680 | 613 | 609.6 | 26 | 44 | 648 | 654 | 5 | 3 | 27 | 20 | M24 | 12 | 7 |

| 650 | 825 | 770 | 735 | 664 | 660.4 | 26 | 48 | 702 | 708 | 5 | 3 | 27 | 24 | M24 | 12 | 7 |

| 700 | 875 | 820 | 785 | 715 | 711.2 | 26 | 48 | 751 | 758 | 5 | 3 | 27 | 24 | M24 | 12 | 7 |

| 750 | 945 | 880 | 840 | 766 | 762 | 28 | 52 | 802 | 810 | 5 | 3 | 33 | 24 | M30 | 12 | 7 |

| 800 | 995 | 930 | 890 | 817 | 812.8 | 28 | 52 | 854 | 862 | 5 | 3 | 33 | 24 | M30 | 13 | 8 |

| 850 | 1045 | 980 | 940 | 868 | 863.6 | 28 | 54 | 904 | 912 | 5 | 3 | 33 | 24 | M30 | 13 | 8 |

| 900 | 1095 | 1030 | 990 | 919 | 914.4 | 30 | 56 | 956 | 964 | 5 | 3 | 33 | 24 | M30 | 13 | 8 |

| 1000 | 1195 | 1130 | 1090 | 1021 | 1016 | 32 | 60 | 1058 | 1066 | 5 | 3 | 33 | 28 | M30 | 14 | 9 |

| *(1100) | 1305 | 1240 | 1200 | 1123 | 1117.6 | 32 | 3 | 33 | 28 | M30 | ||||||

| *1200 | 1420 | 1350 | 1305 | 1225 | 1219.2 | 34 | – | – | 3 | 33 | 32 | M30 | ||||

| *1350 | 1575 | 1505 | 1460 | – | 1371.6 | 34 | – | – | – | – | 3 | 33 | 32 | M30 | ||

| *1500 | 1730 | 1660 | 1615 | – | 1524 | 36 | – | – | – | – | 3 | 33 | 36 | M30 | ||

| Nominal Diameter of Flanges | Outside Diameter of Flanges D | flange Sectional Dimensions | Size Of Bolt | Welding | ||||||||||||

| Diameter of Bolt Circle C | Diameter Of raised Face g | Inside DaimeterOf Flange do | O.D. Of Applicable pipe | t | T | Hub Diameter | Radius r | Raised Face f | Hole Diameter Of H | Bolt Holes Number | ||||||

| a | b | W1 | W2 | |||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 12 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 2.5 |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 12 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 3 |

| 20 | 100 | 75 | 56 | 27.7 | 27.2 | 14 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 3 |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 14 | – | – | – | – | 1 | 19 | 4 | M16 | 5 | 3 |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 65 | 175 | 140 | 116 | 77.1 | 76.3 | 18 | – | – | – | – | 2 | 19 | 4 | M16 | 6.5 | 4 |

| 80 | 185 | 150 | 126 | 90 | 89.1 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 6.5 | 4 |

| -90 | 195 | 160 | 136 | 102.6 | 101.6 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 6.5 | 4 |

| 100 | 210 | 175 | 151 | 115.4 | 114.3 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 7 | 4 |

| 125 | 250 | 210 | 182 | 141.2 | 139.8 | 20 | – | – | – | – | 2 | 23 | 8 | M20 | 7.5 | 4 |

| 150 | 280 | 240 | 212 | 166.6 | 165.2 | 22 | – | – | – | – | 2 | 23 | 8 | M20 | 8 | 5 |

| -175 | 305 | 265 | 237 | 192.1 | 190.7 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 5 |

| 200 | 330 | 290 | 262 | 218 | 216.3 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 6 |

| -255 | 350 | 310 | 282 | 243.7 | 241.8 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 6 |

| 250 | 400 | 355 | 324 | 269.5 | 267.4 | 24 | 36 | 288 | 292 | 6 | 2 | 25 | 12 | M22 | 10 | 6 |

| 300 | 445 | 400 | 368 | 321 | 318.5 | 24 | 38 | 340 | 346 | 6 | 3 | 25 | 16 | M22 | 10 | 6 |

| 350 | 490 | 445 | 413 | 358.1 | 355.6 | 26 | 42 | 380 | 386 | 6 | 3 | 25 | 16 | M22 | 12 | 7 |

| 400 | 560 | 510 | 475 | 409 | 406.4 | 28 | 44 | 436 | 442 | 6 | 3 | 27 | 16 | M24 | 12 | 7 |

| 450 | 620 | 565 | 530 | 460 | 457.2 | 30 | 48 | 496 | 502 | 6 | 3 | 27 | 20 | M24 | 14 | 8 |

| 500 | 675 | 620 | 585 | 511 | 508 | 30 | 48 | 548 | 554 | 6 | 3 | 27 | 20 | M24 | 14 | 8 |

| 550 | 745 | 680 | 640 | 562 | 558.8 | 32 | 52 | 604 | 610 | 6 | 3 | 33 | 20 | M30 | 15 | 9 |

| 600 | 795 | 730 | 690 | 613 | 609.6 | 32 | 52 | 656 | 662 | 6 | 3 | 33 | 24 | M30 | 16 | 10 |

| 650 | 845 | 780 | 740 | 664 | 660.4 | 34 | 56 | 706 | 712 | 6 | 3 | 33 | 24 | M30 | 16 | 10 |

| 700 | 905 | 840 | 800 | 715 | 711.2 | 34 | 58 | 762 | 770 | 6 | 3 | 33 | 24 | M30 | 17 | 10 |

| 750 | 970 | 900 | 855 | 766 | 762 | 36 | 62 | 816 | 824 | 6 | 3 | 33 | 24 | M30 | 18 | 11 |

| 800 | 1020 | 950 | 905 | 817 | 812.8 | 36 | 64 | 868 | 876 | 6 | 3 | 33 | 28 | M30 | 19 | 12 |

| -850 | 1070 | 1000 | 955 | 868 | 863.6 | 36 | 66 | 920 | 928 | 6 | 3 | 33 | 28 | M30 | 19 | 12 |

| 900 | 1120 | 1050 | 1005 | 919 | 914.4 | 38 | 70 | 971 | 979 | 6 | 3 | 33 | 28 | M30 | 22 | 14 |

| 1000 | 1235 | 1160 | 1110 | 1021 | 1016 | 40 | 74 | 1073 | 1081 | 6 | 3 | 39 | 28 | M36 | 22 | 14 |

| *(1100) | 1345 | 1270 | 1220 | 1123 | 1117.6 | 42 | – | – | – | – | 3 | 39 | 28 | M36 | ||

| *1200 | 1465 | 1380 | 1325 | 1225 | 1219.2 | 44 | – | – | – | – | 3 | 39 | 32 | M36 | ||

| *1350 | 1630 | 1540 | 1480 | – | 1371.6 | 48 | – | – | – | – | 3 | 45 | 36 | M42 | ||

| *1500 | 1795 | 1700 | 1635 | – | 1524 | 50 | – | – | – | – | 3 | 45 | 40 | M42 | ||

| Nominal Diameter of Flanges | Outside Diameter of Flanges D | flange Sectional Dimensions | Size Of Bolt | |||||||||||

| Diameter of Bolt Circle C | Diameter Of raised Face g | Inside DaimeterOf Flange do | O.D. Of Applicable pipe | t | T | Hub Diameter | Radius r | Raised Face f | Hole Diameter Of H | Bolt Holes Number | ||||

| a | b | |||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 12 | 16 | 26 | 28 | 4 | 1 | 15 | 4 | M12 |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 12 | 16 | 30 | 32 | 4 | 1 | 15 | 4 | M12 |

| 20 | 100 | 75 | 56 | 27.7 | 27..2 | 14 | 20 | 38 | 42 | 4 | 1 | 15 | 4 | M12 |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 14 | 20 | 46 | 50 | 4 | 1 | 19 | 4 | M16 |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 16 | 22 | 56 | 60 | 5 | 2 | 19 | 4 | M16 |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 16 | 24 | 62 | 66 | 5 | 2 | 19 | 4 | M16 |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 16 | 24 | 76 | 80 | 5 | 2 | 19 | 8 | M16 |

| 65 | 175 | 140 | 116 | 77.1 | 76.3 | 18 | 26 | 94 | 98 | 5 | 2 | 19 | 8 | M16 |

| 80 | 200 | 160 | 132 | 90 | 89.1 | 20 | 28 | 108 | 112 | 6 | 2 | 23 | 8 | M20 |

| -90 | 210 | 170 | 145 | 102.6 | 101.6 | 20 | 30 | 120 | 124 | 6 | 2 | 23 | 8 | M20 |

| 100 | 225 | 185 | 160 | 115.4 | 114.3 | 22 | 34 | 134 | 138 | 6 | 2 | 23 | 8 | M20 |

| 125 | 270 | 225 | 195 | 141.2 | 139.8 | 22 | 34 | 164 | 170 | 6 | 2 | 25 | 8 | M22 |

| 150 | 305 | 260 | 230 | 166.6 | 165.2 | 24 | 38 | 196 | 202 | 6 | 2 | 25 | 12 | M22 |

| 200 | 350 | 305 | 275 | 218 | 216.3 | 26 | 40 | 244 | 252 | 6 | 2 | 25 | 12 | M22 |

| 250 | 430 | 380 | 345 | 269.5 | 267.4 | 28 | 44 | 304 | 312 | 6 | 2 | 27 | 12 | M24 |

| 300 | 480 | 430 | 395 | 321 | 318.5 | 30 | 48 | 354 | 364 | 8 | 3 | 27 | 16 | M24 |

| 350 | 540 | 480 | 440 | 358.1 | 355.6 | 34 | 52 | 398 | 408 | 8 | 3 | 33 | 16 | M30X3 |

| 400 | 605 | 540 | 495 | 409 | 406.4 | 38 | 60 | 446 | 456 | 10 | 3 | 33 | 16 | M30X3 |

| 450 | 675 | 605 | 560 | 460 | 457.2 | 40 | 64 | 504 | 514 | 10 | 3 | 33 | 20 | M30X3 |

| 500 | 730 | 660 | 615 | 511 | 508 | 42 | 68 | 558 | 568 | 10 | 3 | 33 | 20 | M30X3 |

| -550 | 795 | 720 | 670 | 562 | 558.8 | 44 | 70 | 612 | 622 | 10 | 3 | 39 | 20 | M36X3 |

| 600 | 845 | 770 | 720 | 613 | 609.6 | 46 | 74 | 666 | 676 | 10 | 3 | 39 | 24 | M36X3 |

| -650 | 895 | 820 | 770 | 664 | 660.4 | 48 | 77 | 704 | 726 | 10 | 5 | 39 | 24 | M36X3 |

| 700 | 960 | 875 | 820 | 715 | 711.2 | 50 | 80 | 754 | 776 | 10 | 5 | 42 | 24 | M39X3 |

| -750 | 1020 | 935 | 880 | 766 | 762 | 52 | 83 | 806 | 832 | 10 | 5 | 42 | 24 | M39X3 |

| 800 | 1085 | 990 | 930 | 817 | 812.8 | 54 | 86 | 865 | 885 | 10 | 5 | 48 | 24 | M45X3 |

| -850 | 1135 | 1040 | 980 | 868 | 863.6 | 56 | 89 | 916 | 936 | 10 | 5 | 48 | 24 | M45X3 |

| 900 | 1185 | 1090 | 1030 | 919 | 914.4 | 58 | 93 | 968 | 986 | 10 | 5 | 48 | 28 | M45X3 |

| 1000 | 1320 | 1210 | 1140 | 1021 | 1016 | 62 | 99 | 1070 | 1098 | 12 | 5 | 56 | 28 | M52X3 |

| -1100 | 1420 | 1310 | 1240 | 1123 | 1117.6 | 66 | 105 | 1180 | 1200 | 12 | 5 | 56 | 32 | M52X3 |

| 1200 | 1530 | 1420 | 1350 | 1225 | 1219.2 | 70 | 112 | 1282 | 1302 | 12 | 5 | 56 | 32 | M52X3 |

| Nominal Diameter of Flanges | Outside Diameter of Flanges D | flange Sectional Dimensions | Reference | |||||||||||||||||

| Diameter of Bolt Circle C | Diameter Of raised Face g | Inside DaimeterOf Flanges do | O.D. of Steel pipe | t | T | Hub Diameter | Radius r | f | D | Bolt Holes Number | Holes Dia. H | SIZE Of Bolt | S1 | M | S2 | N | L | |||

| a | b | |||||||||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 14 | 20 | 30 | 32 | 4 | 1 | – | 4 | 15 | M12 | 27 | 4 | 27 | 4 | – |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 14 | 20 | 34 | 36 | 4 | 1 | – | 4 | 15 | M12 | 31 | 4 | 31 | 4 | – |

| 20 | 100 | 75 | 56 | 27.7 | 27.2 | 16 | 22 | 40 | 42 | 4 | 1 | – | 4 | 15 | M12 | 37 | 4 | 37 | 4 | – |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 16 | 24 | 48 | 50 | 4 | 1 | 4 | 19 | M16 | 44 | 4 | 44 | 4.5 | – | |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 18 | 26 | 56 | 60 | 5 | 2 | – | 4 | 19 | M16 | 52 | 4 | 53 | 5 | – |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 18 | 26 | 62 | 66 | 5 | 2 | – | 4 | 19 | M16 | 58 | 4 | 59 | 5.5 | – |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 18 | 26 | 76 | 80 | 5 | 2 | – | 8 | 19 | M16 | 70 | 4 | 72 | 5.5 | – |

| 65 | 175 | 140 | 116 | 77.7 | 76.3 | 20 | 30 | 100 | 104 | 5 | 2 | 65.9 | 8 | 19 | M16 | 94 | 6 | – | – | 6 |

| 80 | 200 | 160 | 132 | 90 | 89.1 | 22 | 34 | 113 | 117 | 6 | 2 | 78.1 | 8 | 23 | M20 | 107 | 6 | – | – | 6 |

| -90 | 210 | 170 | 145 | 102.6 | 101.6 | 24 | 36 | 126 | 130 | 6 | 2 | 90.2 | 8 | 23 | M20 | 120 | 6 | – | – | 6 |

| 100 | 225 | 185 | 160 | 115.4 | 114.3 | 24 | 36 | 138 | 142 | 6 | 2 | 102.3 | 8 | 23 | M20 | 132 | 6 | – | – | 6 |

| 125 | 270 | 225 | 195 | 141.2 | 139.8 | 26 | 40 | 166 | 172 | 6 | 2 | 126.6 | 8 | 25 | M22 | 160 | 7 | – | – | 6 |

| 150 | 305 | 260 | 230 | 166.6 | 165.2 | 28 | 42 | 196 | 202 | 6 | 2 | 151 | 12 | 25 | M22 | 186 | 8 | – | – | 6 |

| 200 | 350 | 305 | 275 | 218 | 216.3 | 30 | 46 | 244 | 252 | 6 | 2 | 199.9 | 12 | 25 | M22 | 237 | 9 | – | – | 6 |

| 250 | 430 | 380 | 345 | 269.5 | 267.4 | 34 | 52 | 304 | 312 | 6 | 2 | 248.8 | 12 | 27 | M24 | 290 | 10 | – | – | 6 |

| 300 | 480 | 430 | 395 | 321 | 318.5 | 36 | 56 | 354 | 364 | 8 | 3 | 297.9 | 16 | 27 | M24 | 345 | 11 | – | – | 6 |

| 350 | 540 | 480 | 440 | 358.1 | 355.6 | 40 | 62 | 398 | 408 | 8 | 3 | 333.4 | 16 | 33 | M30X3 | 384 | 12 | – | – | 6 |

| 400 | 605 | 540 | 495 | 409 | 406.4 | 46 | 70 | 446 | 456 | 10 | 3 | 381 | 16 | 33 | M30X3 | 437 | 13 | – | – | 7 |

| 450 | 675 | 605 | 560 | 460 | 457.2 | 48 | 78 | 504 | 514 | 10 | 3 | 431.8 | 20 | 33 | M30X3 | 490 | 15 | – | – | 7 |

| 500 | 730 | 660 | 615 | 511 | 508 | 50 | 84 | 558 | 568 | 10 | 3 | 482.6 | 20 | 33 | M30X3 | 544 | 16 | – | – | 7 |

| -550 | 795 | 720 | 670 | 562 | 558.8 | 52 | 90 | 612 | 622 | 10 | 3 | 533.4 | 20 | 39 | M36X3 | 595 | 16 | – | – | 7 |

| 600 | 845 | 770 | 720 | 613 | 609.6 | 54 | 96 | 666 | 676 | 10 | 3 | 584.2 | 24 | 39 | M36X3 | 646 | 18 | – | – | 7 |

| *650 | 945 | 850 | 790 | 664 | 660.4 | 60 | 5 | 24 | 48 | M45X3 | ||||||||||

| *700 | 995 | 900 | 840 | 715 | 711.2 | 64 | 5 | 24 | 48 | M45X3 | ||||||||||

| *750 | 1080 | 970 | 900 | 766 | 762 | 68 | 5 | 24 | 56 | M52X3 | ||||||||||

| *800 | 1140 | 1030 | 960 | 817 | 812.8 | 72 | 5 | 24 | 56 | M52X3 | ||||||||||

| *850 | 1200 | 1090 | 1020 | 868 | 863.6 | 74 | 5 | 24 | 56 | M52X3 | ||||||||||

| *900 | 1250 | 1140 | 1070 | 919 | 914.4 | 76 | 5 | 28 | 56 | M52X3 | ||||||||||

Korean industrial flanges Standards

Korean industrial flanges are governed by several standards that ensure their compatibility, durability, and performance in various industrial applications. These standards are primarily set by Korean Standards (KS) and align with JIS (Japanese Industrial Standards) for many flange types. The key Korean industrial flange standards include:

-

KS B 1501 - Steel Flanges

Covers design, dimensions, and material requirements for steel flanges used in pressure piping systems. Common types include weld neck, slip-on, blind, and socket weld flanges, primarily used in oil & gas, petrochemical, and power industries. -

KS D 1501 - Flanges for Gas Pipelines

Specifies materials and pressure ratings for flanges used in gas pipelines to ensure secure seals and reliable performance. -

JIS B 2220 - Flanges for Pipes

Defines flange dimensions, materials, and pressure ratings, closely aligning with ASME B16.5. Types include weld neck, slip-on, blind, threaded, and socket weld, with pressure classes like 150, 300, and 600. -

KS B 1502 - Cast Iron Flanges

Focuses on cast iron flanges for moderate pressure systems, typically used in water, sewage, and other lower-pressure fluids. -

JIS B 2311 - Flanges for High-Pressure Applications

Specifies flanges designed to withstand high pressure and temperature, used in critical systems in oil, gas, and petrochemical industries. -

KS F 5103 - Stainless Steel Flanges

Details material and performance requirements for stainless steel flanges, ideal for high-corrosion environments in industries like chemical processing and pharmaceuticals.

Why Ample Alloys For Korean weld neck flanges !

Adherence to Korean Standards

Ample Alloys ensures all Korean flanges meet the rigorous standards such as KS B 1501, KS D 1501, and JIS B 2220. Our flanges are designed to meet specific dimensional, material, and pressure class requirements, ensuring reliability and durability in industrial applications.

Wide Range of Flanges

We offer a comprehensive range of Korean flanges, including weld neck, slip-on, blind, and socket weld flanges, designed for various industries such as oil & gas, petrochemical, and power generation.

Proven Industry Expertise

With years of experience in manufacturing and supplying industrial flanges, Ample Alloys has built a reputation for delivering quality products and solutions tailored to our clients' needs.

Competitive Pricing and Timely Delivery

We offer cost-effective pricing without compromising on quality, ensuring your project stays within budget. Our efficient manufacturing and logistics systems ensure on-time delivery.

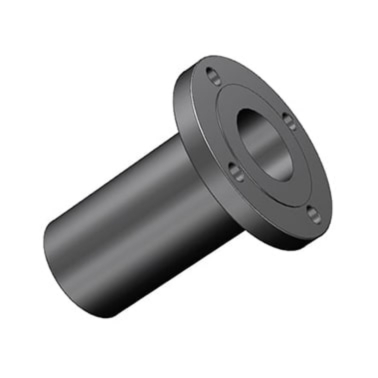

- Weld neck flanges

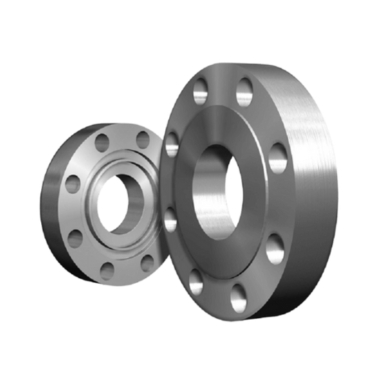

- Slip-on flanges

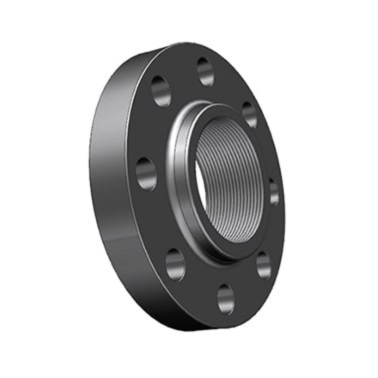

- Blind flanges

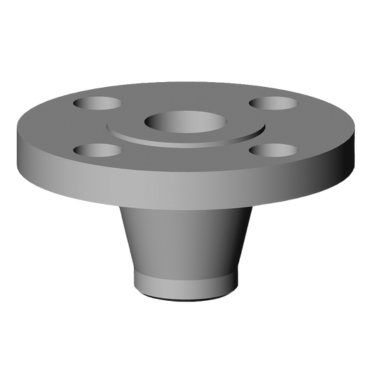

- Socket weld flanges

- Threaded flanges

Yes, Korean flanges are often compatible with other international standards, such as ASME and DIN, due to the similarities in their design, dimensions, and pressure class ratings. However, it’s important to verify compatibility for specific applications.

Yes, Korean flanges can be customized in terms of size, material, and pressure class to meet the specific needs of your project. Whether you require custom dimensions, higher pressure ratings, or special material grades, manufacturers like Ample Alloys can accommodate your requests.